Molecular sieve, and sound absorption material and electro-acoustic device adopting molecular sieve

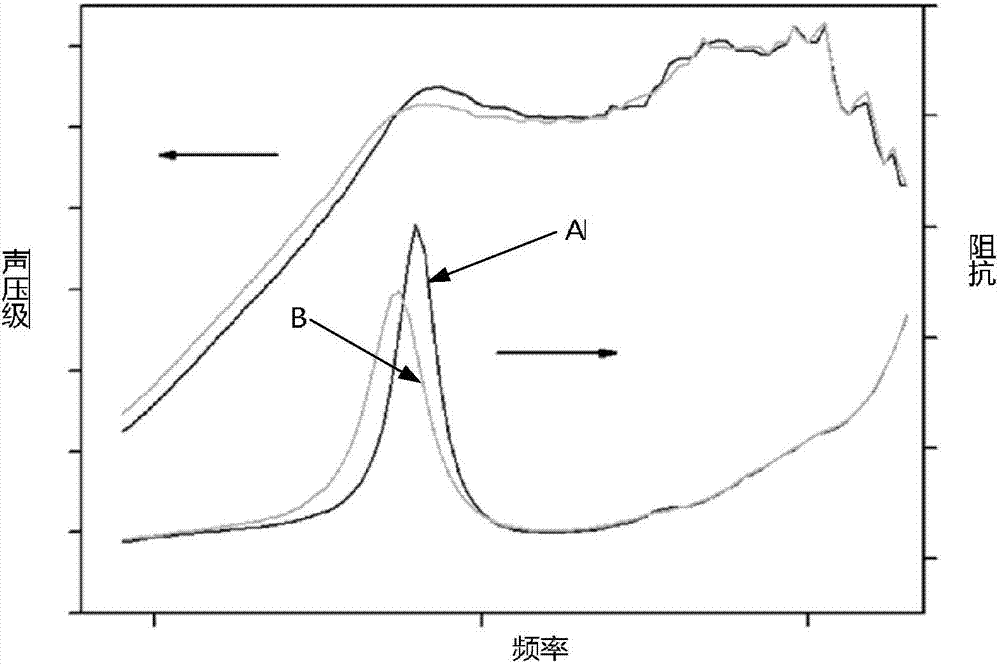

A sound-absorbing material and molecular sieve technology, applied in the field of molecular sieves, can solve problems such as fuzzy composition requirements, achieve good low-frequency performance, increase the sound pressure value, and increase the volume of the cavity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

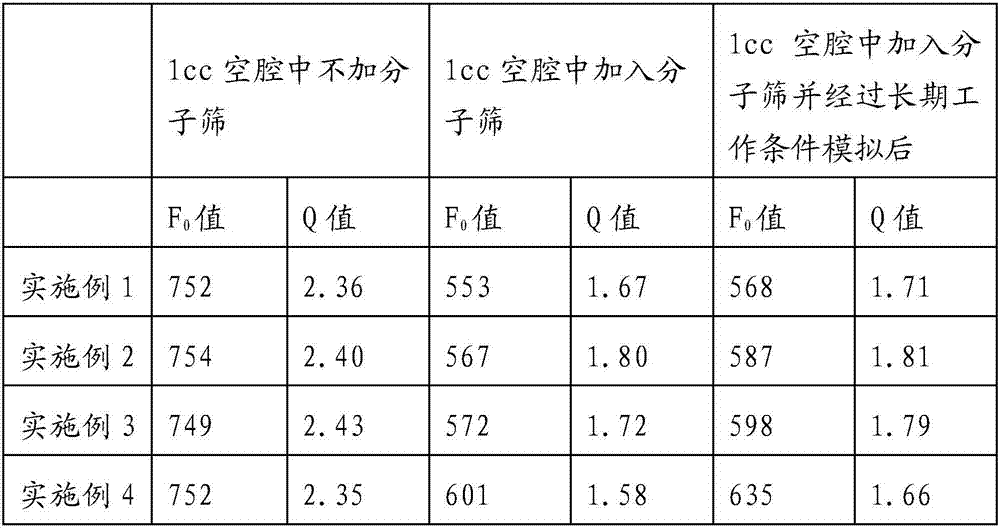

Embodiment 1

[0035] A kind of MFI molecular sieve, its crystal framework component content: SiO 2 98.55%, Al 2 o 3 0.31%; the cation content of the balance skeleton charge: Na20 is 0.39%, CaO is 0.11%, and K2O is 0.23%. The content of each ingredient is less than 100% because it will inevitably contain some other trace ingredients, the type is uncertain, but it will not affect the performance.

Embodiment 2

[0037] A kind of MFI molecular sieve, its crystal framework component content: SiO 2 98.10%, Al 2 o 3 0.42%; cation content to balance the charge of the skeleton: Na 2 O is 0.71%, CaO is 0.14%, K 2 O is 0.21%.

Embodiment 3

[0039] A kind of MFI molecular sieve, its crystal framework component content: SiO 2 98.23%, Al 2 o 3 0.34%; cation content to balance the charge of the skeleton: Na 2 0 is 0.27%, CaO is 0.09%, K 2 O is 0.68%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com