Gallium alloy heat dissipation material provided with fiber framework and production technology thereof

A fiber skeleton and heat dissipation material technology, applied in the mechanical field, can solve problems such as excessive fluidity, poor heat dissipation effect of heat sinks, and increased heat dissipation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific diagrams.

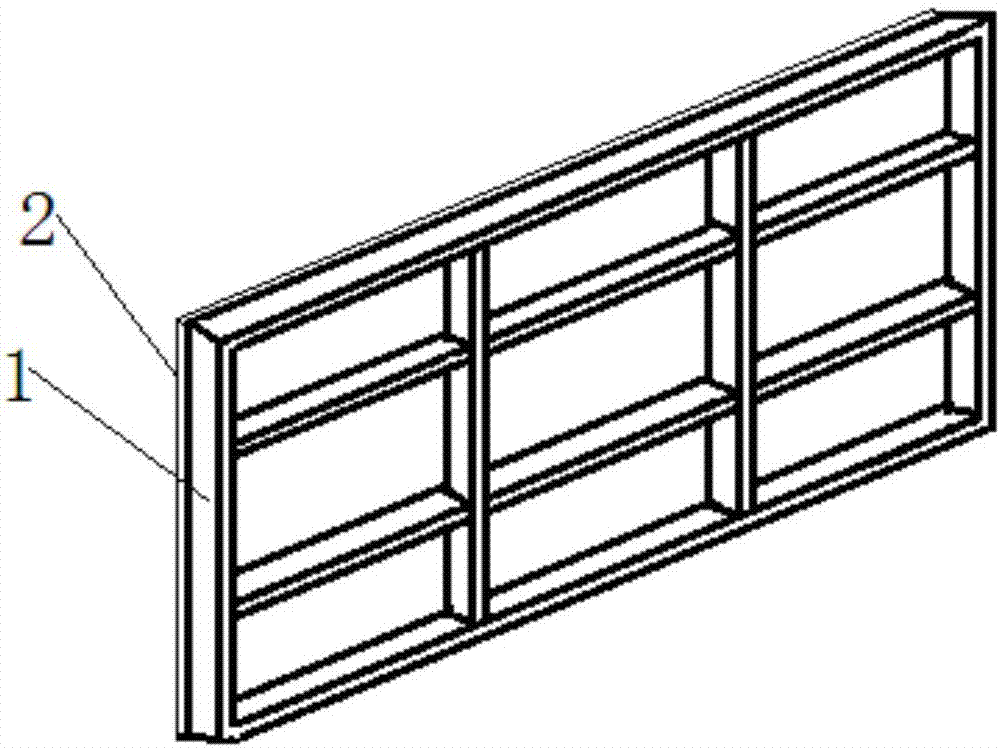

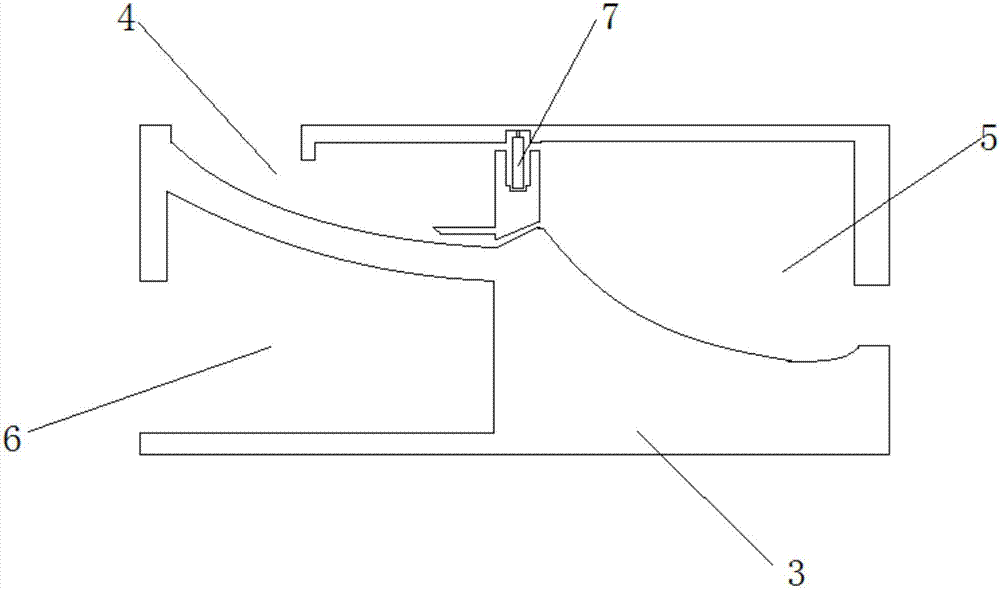

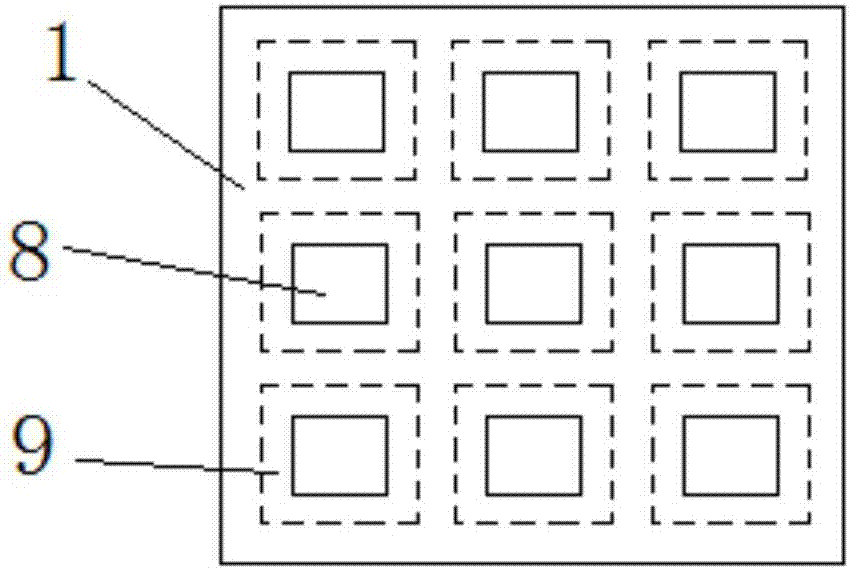

[0053] see figure 1 , figure 2 , image 3, a gallium alloy heat dissipation material with a fiber skeleton, including a carbon fiber mesh 1; the thickness of the carbon fiber mesh is 0.1 mm to 5 mm; mm ~ 5mm; the mesh is a through hole communicating with the front and back; the internal aperture 9 of the through hole is more than 1.5 times larger than the opening diameter 8 on the front side; gallium alloy is embedded in the mesh of the carbon fiber mesh. Because the surface tension of the gallium alloy is extremely strong when it is in a liquid state, the patent also sets a smaller mesh opening diameter and a relatively larger internal aperture of the through hole, so the gallium alloy is perfectly fixed in the carbon fiber mesh. Both can be in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com