A kind of segment color slub yarn production device and production method

A production device and technology for slub yarn, which is applied in the directions of yarn, spinning machine, textile and paper making, etc., can solve the problems of increasing the transformation cost, inconvenient quantitative adjustment and control of roving, etc., and achieve the effect of reducing the transformation cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

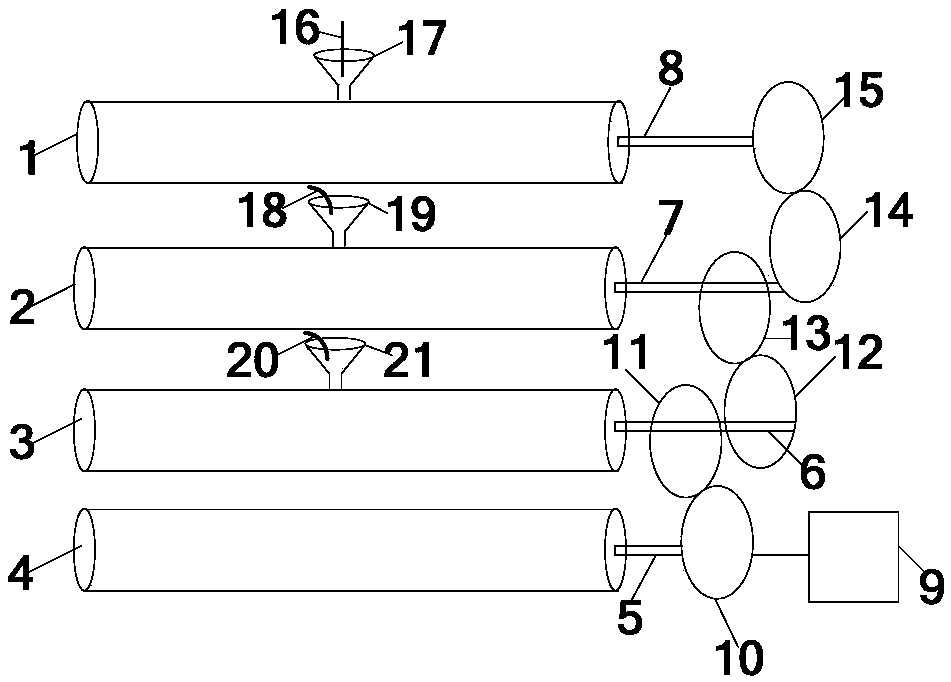

[0009] Depend on figure 1 As shown, a segment color slub yarn production device includes a rear roller 1, a middle rear roller 2, a middle front roller 3, and a front roller 4. The front roller 4 includes a front roller sleeve and a front roller shaft 5, and the front roller sleeve is integrally fixed on On the surface of the front roller shaft, the right end of the front roller shaft stretches out from the right end of the front roller sleeve, and the front roller shaft is driven to rotate by the main motor 9, and a front connecting gear 10 is installed on the right end where the front roller shaft extends out of the front roller sleeve. Connecting teeth are evenly distributed on a circumference of the gear surface. The middle front roller 3 is located at the back and upper part of the front roller. The middle front roller includes a middle front roller sleeve and a middle front roller shaft 6. The middle front roller sleeve is integrally fixed on the middle front roller shaft...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap