Cavity floor with supporting steel mesh bodies with holes

A technology of cavity floor and mesh body, which is applied in the direction of floors, building components, buildings, etc., and can solve problems such as cost and construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The invention will be further described below in conjunction with the accompanying drawings.

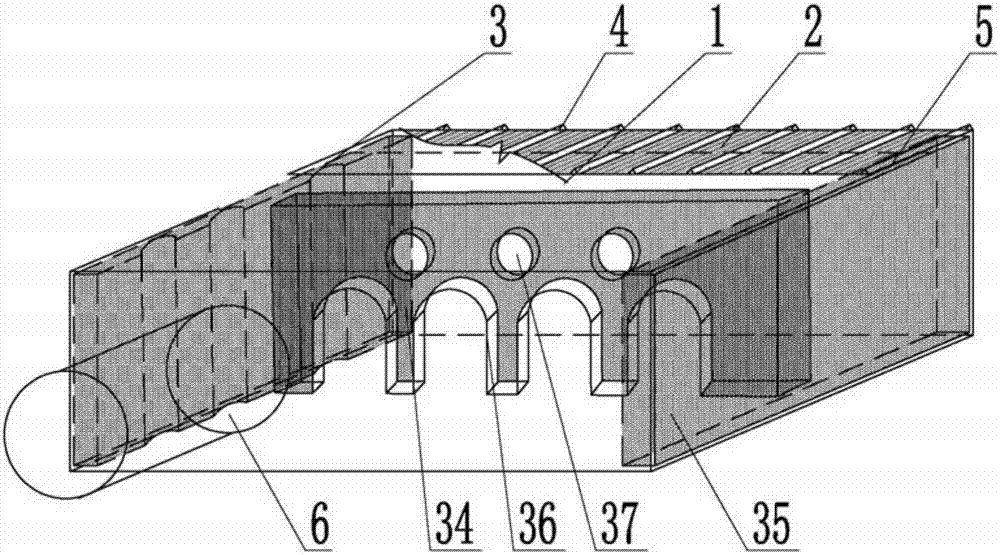

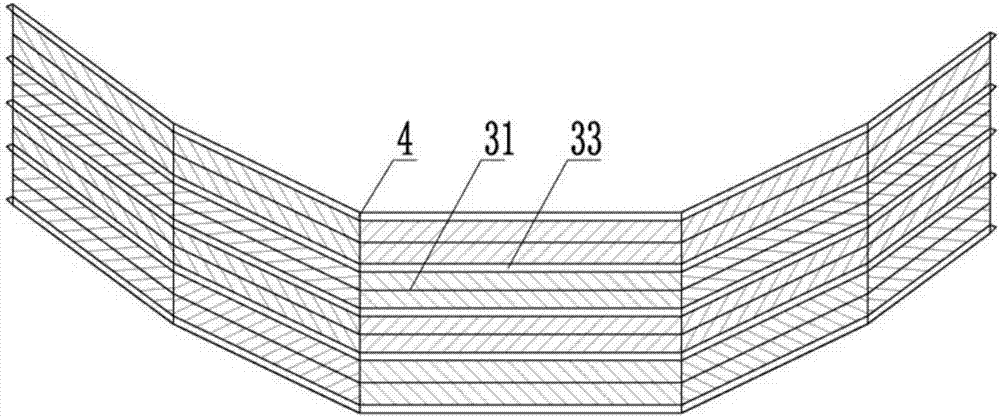

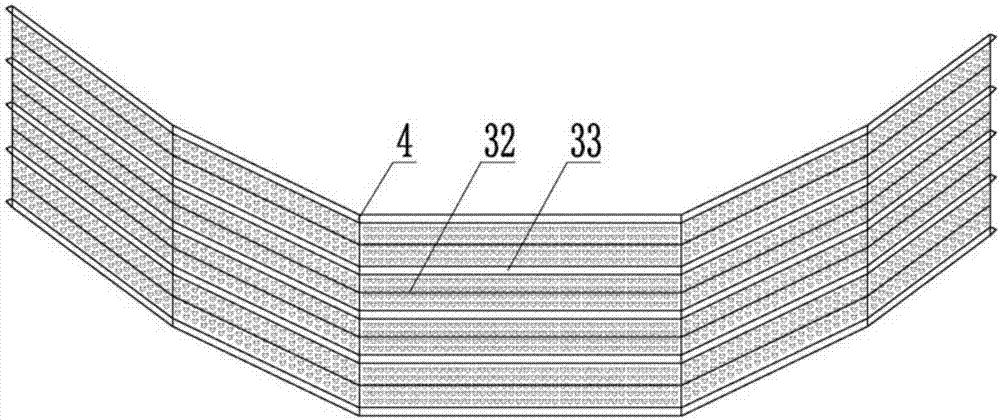

[0021] figure 1 It is an elevation view of a cavity floor supporting steel mesh body with holes in the present invention. When the present invention is implemented, the ribbed steel mesh 2 prepared from the factory is transported to the construction site; The foamed cement blocks of the required specifications are produced on the construction site; the foamed cement blocks are placed in 4 places on the fixed-length mold marks of the ribbed steel mesh, and the ribbed steel mesh wraps the foamed cement blocks along the fixed-scale mold marks, and the foamed cement blocks The block is a support foam cement block 34 and a plugging foam cement block 35, and the support foam cement block 34 lower end has a prefabricated notch 36, and there are N reserved holes 37 in the support foam cement block; There is a prefabricated notch 3 on the inner wall; the two ends of the ribbed steel m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com