Axial flow pump online detecting bearing temperature change

A bearing temperature, axial flow pump technology, applied in non-variable-capacity pumps, components of pumping devices for elastic fluids, pumps, etc., can solve problems such as inability to measure temperature, inability to perform signal transmission, and intermittent temperature measurement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings.

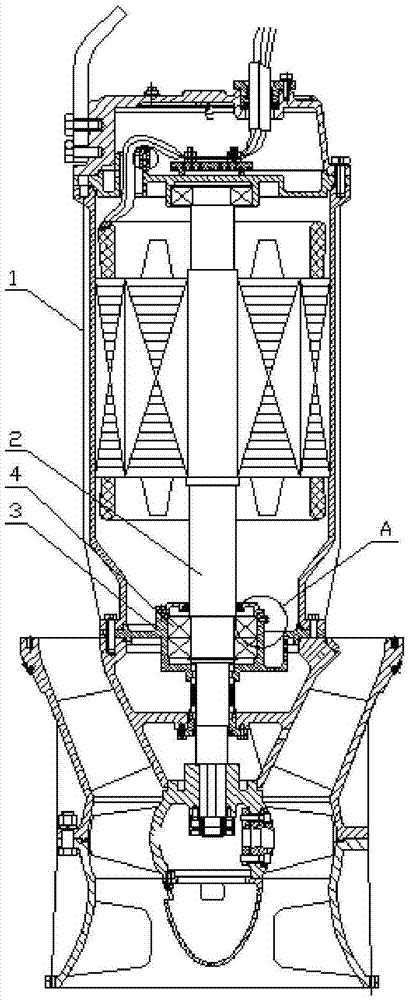

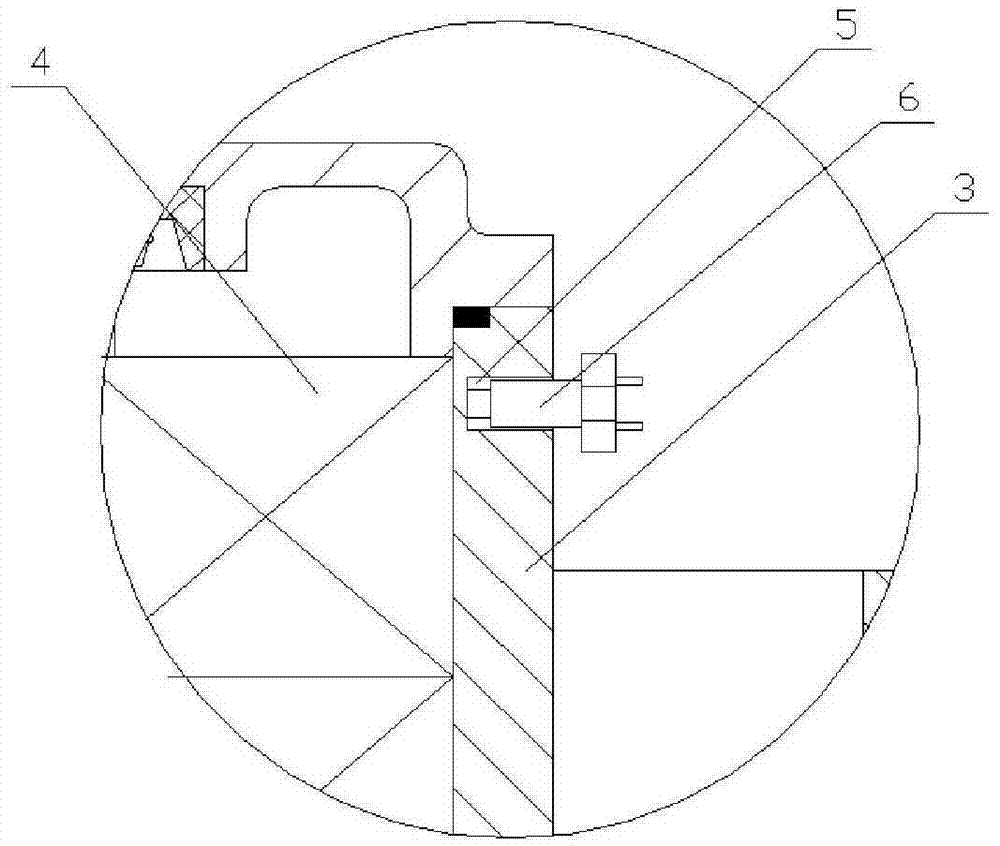

[0016] Such as figure 1 As shown in the structural diagram of the present invention, the present invention provides an axial flow pump for online detection of bearing temperature changes, including a motor casing 1, a pump shaft 2 and a bearing seat 3, and the pump shaft 2 is axially installed on the motor casing 1 Inside, the bearing seat 3 is fixed on the bottom of the motor housing 1 by bolts, a bearing 4 is installed between the bearing seat 3 and the pump shaft 2, and a mounting hole 5 is opened on the outer side of the bearing seat 3 , a temperature sensor 6 is arranged in the installation hole 5 . The mounting hole 5 is opened laterally on the outer side of the bearing seat 3 .

[0017] The model of the temperature sensor 6 is PT100. The output end of the temperature sensor 6 is connected to the control end of the axial flow pump. The temperature sensor 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com