An exhaust valve performance testing system and testing method

A test system and exhaust valve technology, which is applied in mechanical valve testing, mechanical component testing, machine/structural component testing, etc., can solve the problem of single flow meter range, achieve wide application range, avoid waste, and ensure Effect of measurement accuracy and measurement precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

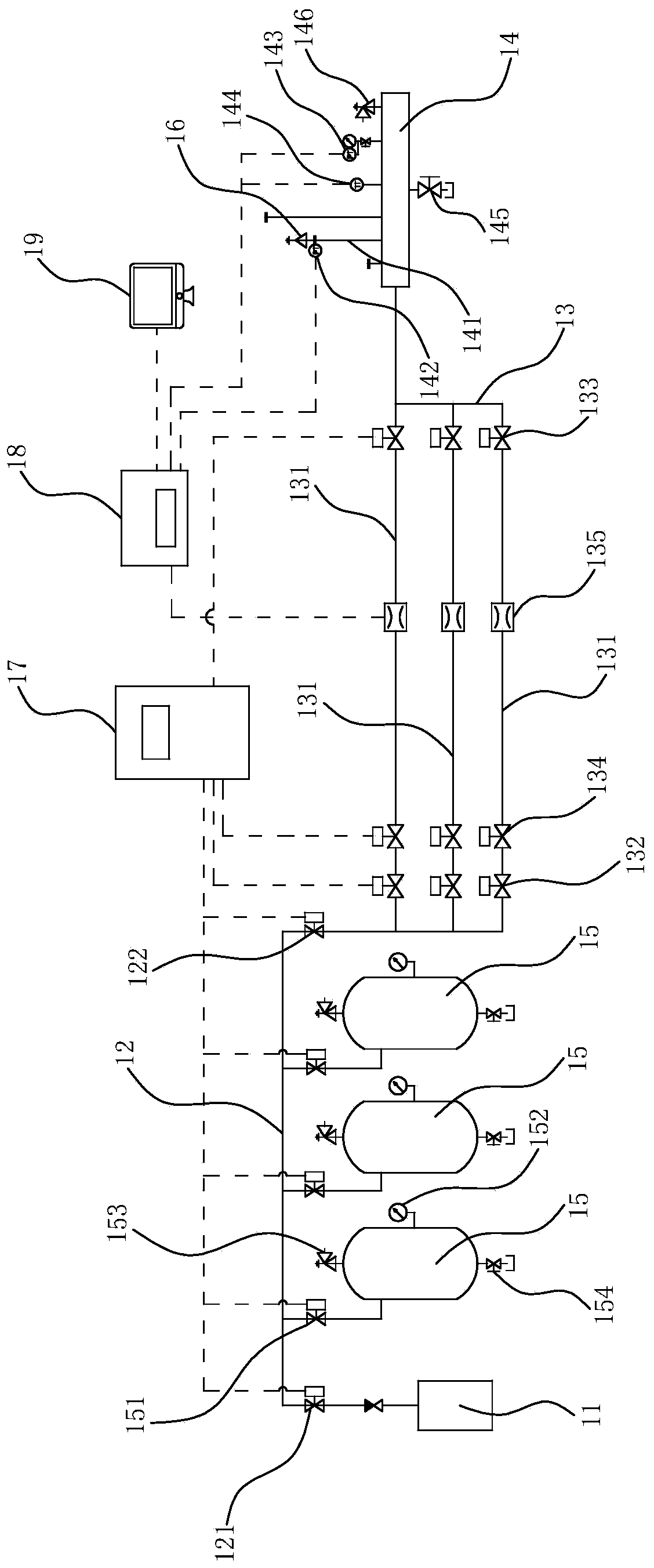

[0031] Such as figure 1 As shown, the exhaust valve performance test system in the present invention includes a compressor 11, a gas storage section pipeline 12, a flow measurement section pipeline 13 and a test container 14 connected in sequence along the gas flow direction, and the compressor 11 is connected to the gas storage section. A main valve 121 is arranged between the section pipelines 12; the gas storage section pipeline 12 is connected with a plurality of gas storage tanks 15 arranged side by side; There is a switch valve 1 151; the flow measurement section pipeline 13 includes a plurality of branch pipelines 131 with different calibers and arranged side by side, each branch pipeline 131 inlet is provided with a switch valve 2 132, and each branch pipeline 131 outlet is provided with On-off valve three 133, the branch pipeline 131 is also provided with a pressure regulating valve 134 and a flow meter 135; the test container 14 is connected with an installation pipe...

Embodiment 2

[0041] The test method of the above-mentioned exhaust valve performance test system comprises the following steps:

[0042] S1, close the main valve two 122, open the main valve one 121 and the switch valve one 151, start the compressor 11, inflate each air storage tank 15 through the compressor 11, after each air storage tank 15 is full, Close the on-off valve one 151 and the main valve one 121;

[0043] S2. According to the caliber parameters of the tested valve 16, determine the number of gas storage tanks 15 required for the test, the number and the caliber of the branch pipelines 131;

[0044] S3, open the main valve two 122 and the on-off valve one 151 of each gas storage tank 15 required for the test, open the required branch pipeline 131 inlet end on-off valve two 132, pressure regulating valve 134 and outlet end on-off valve three 133, After the medium flows out from the gas storage tank 15, it first enters the branch pipeline 131 and then flows into the test contain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com