Fast test method for interface thermal resistance of single power cell

A technology of power battery and interface thermal resistance, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of complex test methods, non-quantitative test methods, complex test instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

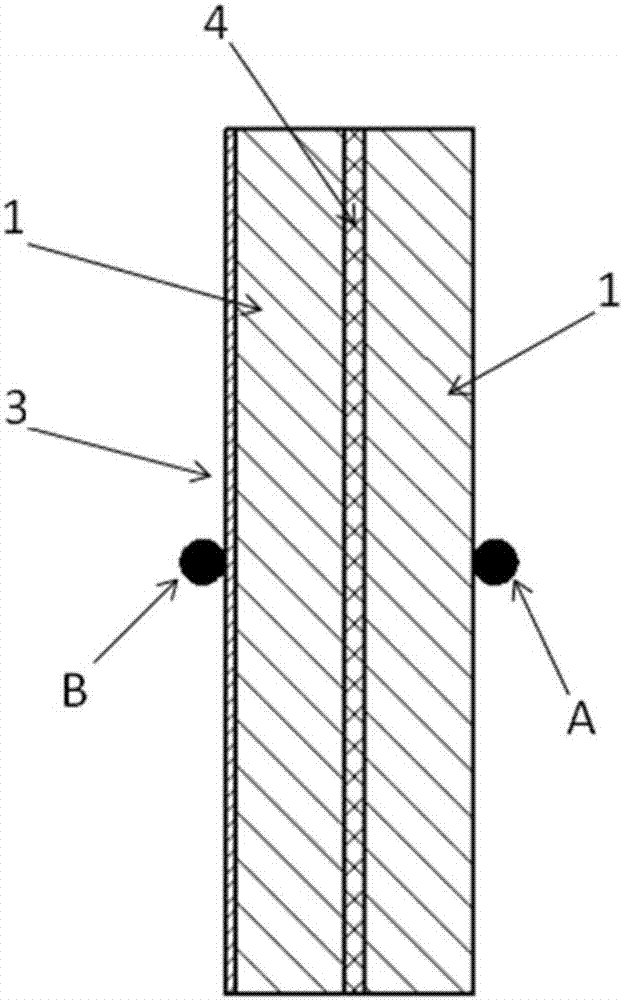

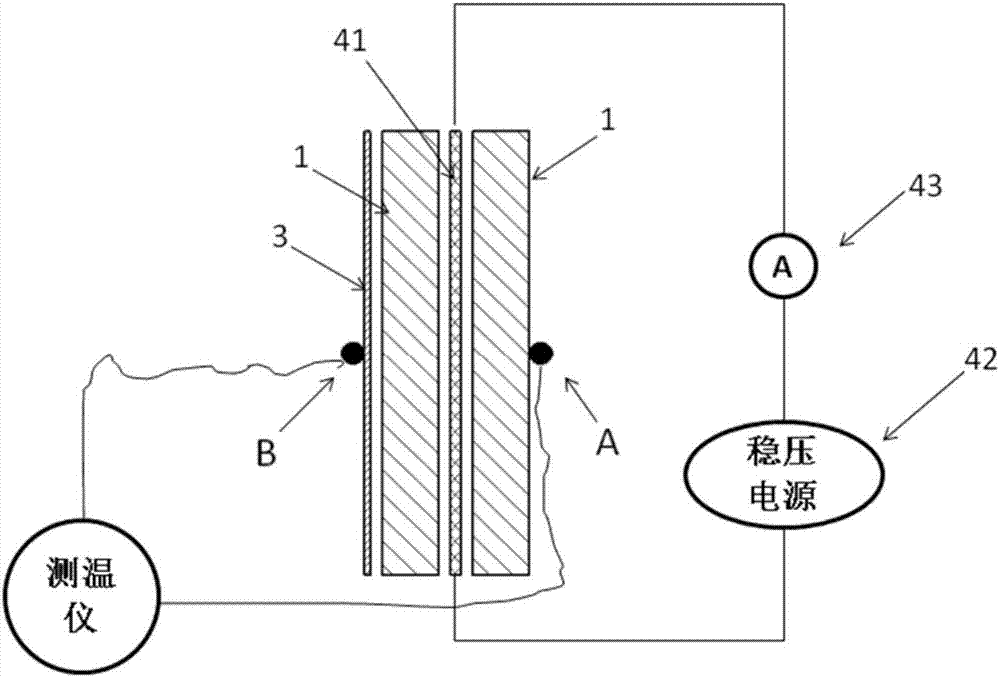

[0025] This embodiment provides a rapid test method for the interface thermal resistance of a power battery cell, which uses a test device to complete the test. The test device includes a heating unit, a heat conduction unit, and two identical power battery cells; the heating unit is Clamped between the two power battery cells, the heat conduction unit covers the left surface of the power battery cell on the left side, and the central points of the heat generating unit, the heat conduction unit and the two power battery cells coincide.

[0026] The method comprises the steps of:

[0027] S10. Place the test device above in a constant temperature environment and place it in the air; for example, the test device can be placed in environments with different temperatures to complete the interface thermal resistance of power battery cells at different temperatures.

[0028] S20. The heating unit emits heat to start heating the power battery unit.

[0029] In this embodiment, when ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com