Power module integrated with water-cooled radiator

A water-cooled radiator, power module technology, applied in the direction of electric solid device, semiconductor device, semiconductor/solid-state device parts, etc. The effect of high sealing, reasonable structure and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

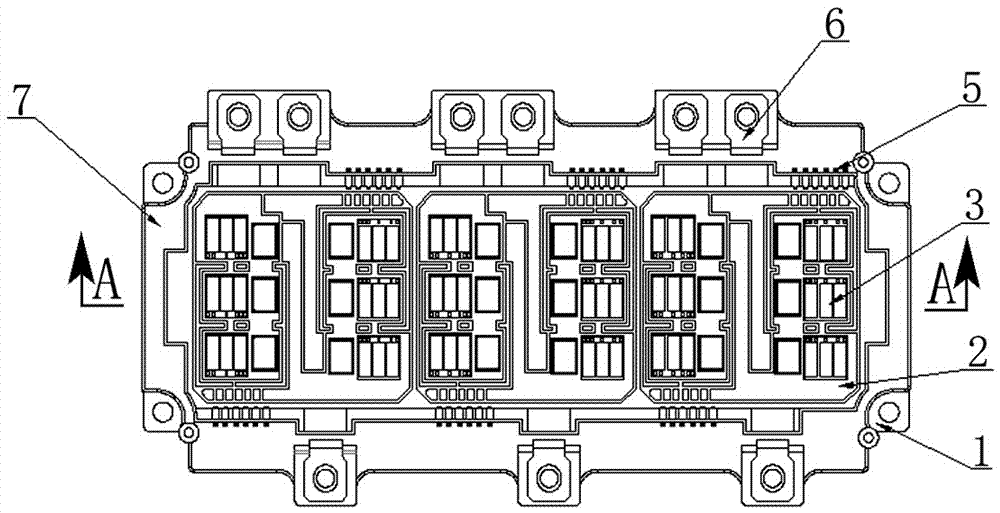

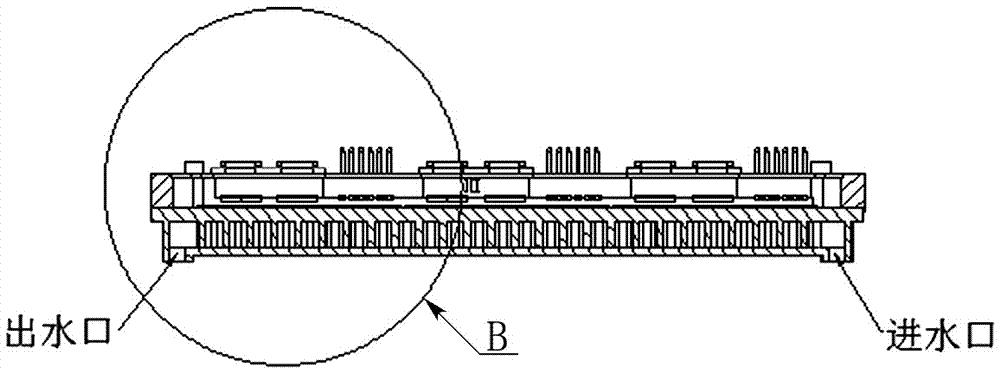

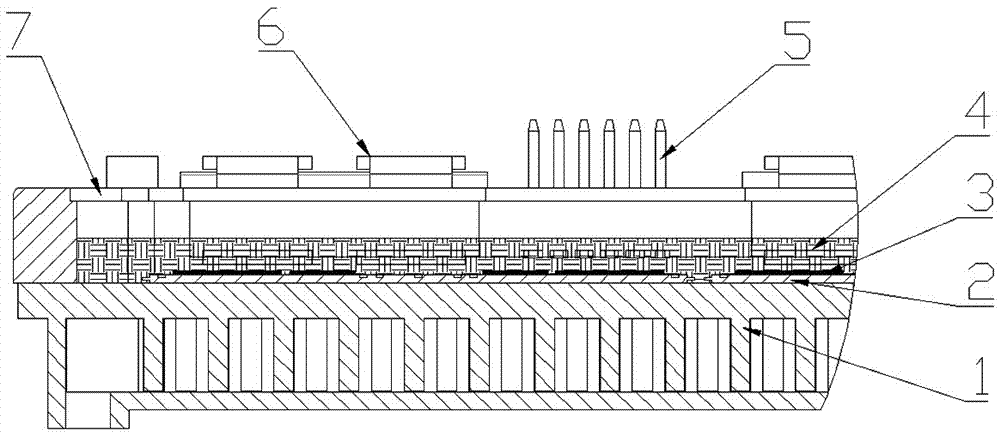

[0018] The present invention will be further described below in conjunction with accompanying drawing. Figure 1-3 As shown, a power module with an integrated water-cooled radiator includes a heat-dissipating substrate 1 integrated with a water-cooled radiator, an insulating substrate 2 welded to the heat-dissipating substrate by reflow, and a chip 3 welded to the insulating substrate 2 to realize chip 3 and the insulating substrate. 2 Aluminum wires electrically connected to the copper layer on the surface, silicone gel 4 for protecting the chip 3 and the aluminum wires, a plastic case 7 covering the power terminals 6, the front of the heat dissipation substrate 1 is bonded to the insulating substrate 2, and the back of the heat dissipation substrate 1 It is a water-cooled radiator, and the bottom of the heat dissipation substrate 1 is provided with at least two water inlets and outlets connected to the external water circulation to form the overall heat dissipation system of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com