Oil-filled pressure balance type pluggable electrical connector

An oil-filled pressure, electrical connector technology, applied in the direction of connection, connecting device components, circuits, etc., can solve the problems of lack of underwater plug-in function, aging, affecting life, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

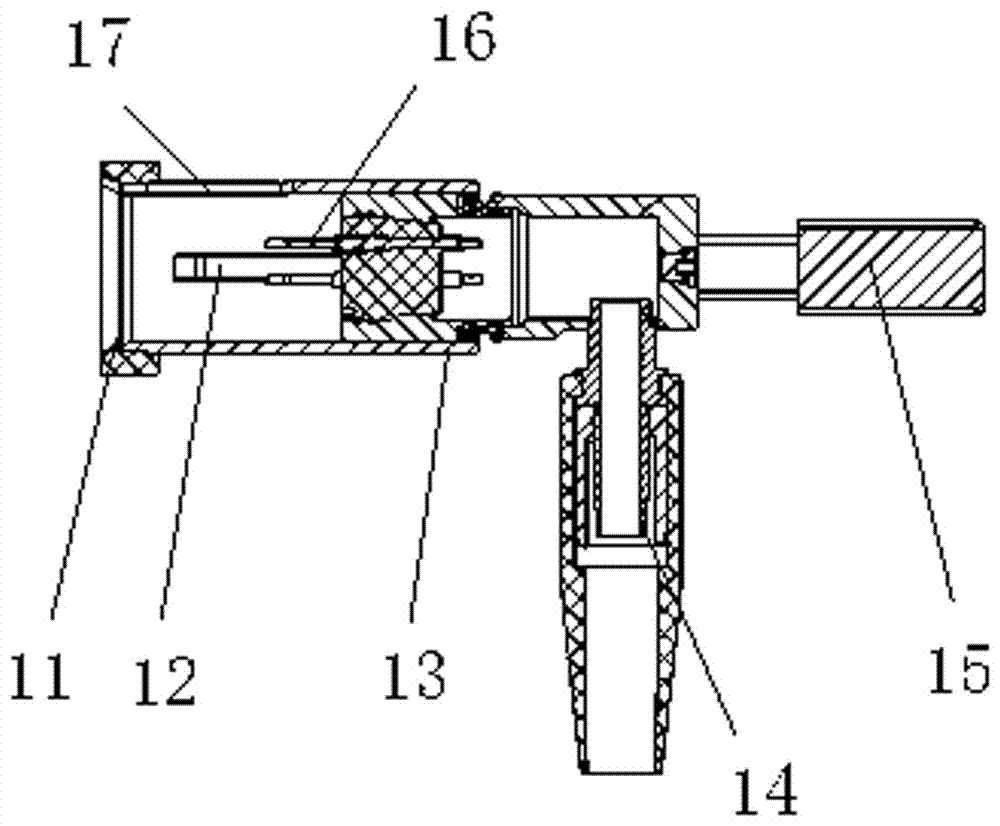

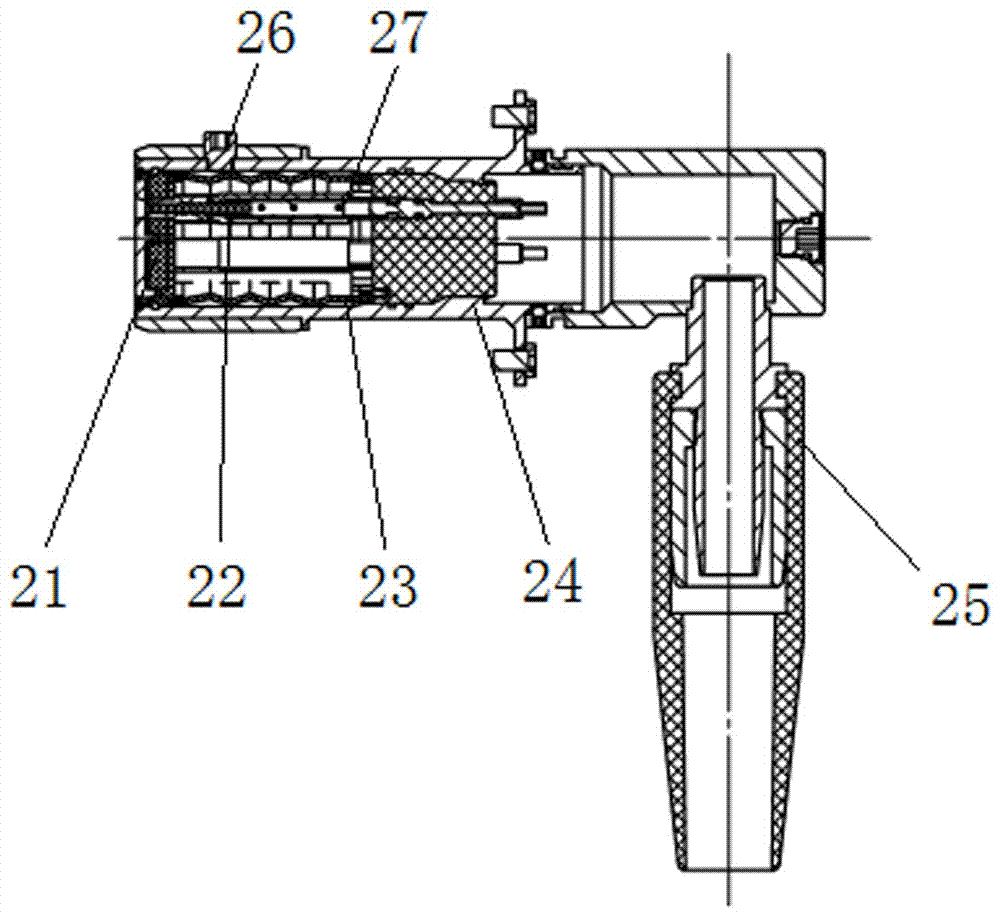

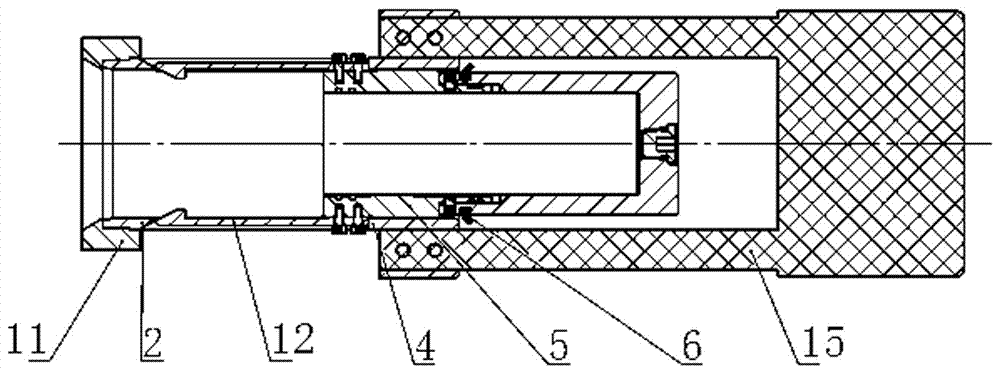

[0028] An oil-filled pressure-balanced underwater plug-and-pull electrical connector, including a plug connector and a socket connector, is characterized in that the plug connector includes

[0029] A floating housing 13, one side of the floating housing 13 is provided with a guide groove 17;

[0030] A plug connector tail attachment 14, the plug connector tail attachment 14 is arranged on one side of the floating housing 13, and the plug connector tail attachment 14 is used to be mated with a cable to form a transmission assembly;

[0031] An electric pin contact couple 16, the electric pin contact couple 16 is arranged in the floating housing 13, the front end of the electric pin contact couple 16 is a bare metal contact point, and the rear end surface is coated with an insulating layer;

[0032] Wide mouth guide structure 11, described wide mouth gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com