Paper cutter with rotatable paper cutting table

A paper cutter and paper cutting technology, applied in metal processing and other directions, can solve problems such as affecting cutting accuracy and paper shift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

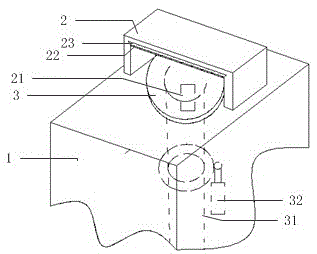

[0012] Such as figure 1 As shown, a paper cutter with a rotatable paper cutting table in the present invention includes a machine base 1, a frame 2 is arranged on the machine base 1, a disc-shaped paper cutting table 3 is arranged on the machine base 1, and the paper cutting machine The connecting column 31 on the lower side of the platform 3 is covered with a gear, which meshes with the driving gear of the motor 32 placed in the machine base 1, so that the paper cutting table is driven to rotate by the motor 32, and the bottom of the connecting column 31 is connected with the hydraulic cylinder , so as to realize the lifting of the paper cutting table.

[0013] The cutter 4 is arranged on the front side of the frame 2 , and the inside of the paper cutting table 3 is provided with a coil 21 which generates magnetism when energized. A flake-shaped magnet block 22 is arranged at the corresponding position on the frame 2, and the magnet block 22 is adsorbed on the magnet end 23 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com