Full-automatic impression, lineation and knife folding all-in-one machine

A fully automatic, all-in-one machine technology, which is applied in the direction of folding thin materials, separating objects, and supplying objects, which can solve the problems of low production efficiency, creasing and scribing folding knives without special equipment, etc., achieve high speed, and solve paper pattern stereotypes Problems, Position-Precise Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

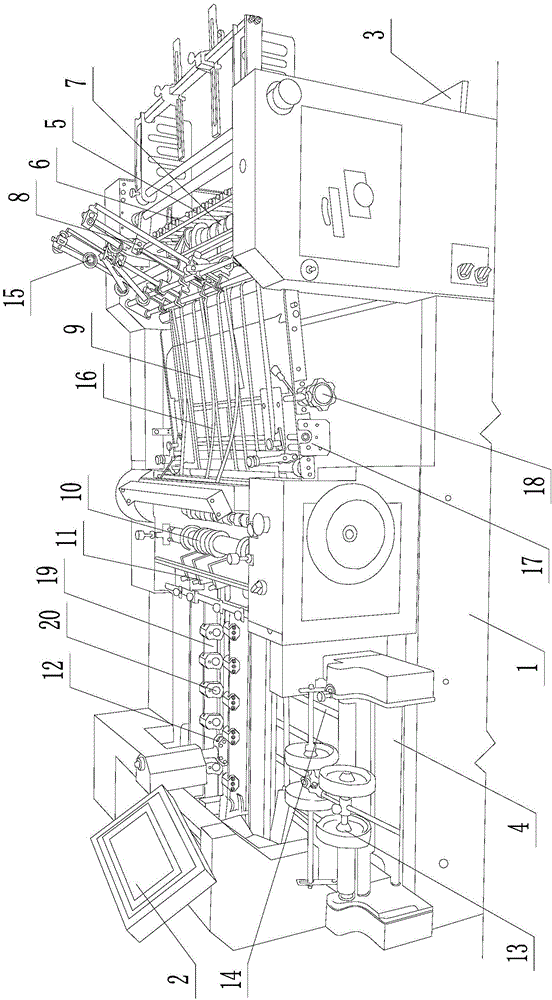

[0016] Such as figure 1 As shown, a fully automatic creasing and scribing folding knife machine includes a body 1 and a control panel 2. The body 1 is provided with a paper feeding table 3, a paper passing mechanism, a creasing part, a scribing part, a folding knife part and The paper output table 4 and the paper feeding table 3 are connected with the paper passing mechanism. The paper passing mechanism is equipped with a plurality of suction nozzles 5, which are connected with the air pump. The suction nozzles 5 are installed on the connecting rod 6, and the connecting rod 6 is rotatable. , one side of the connecting rod 6 is provided with a paper feed roller 7 and a double-sheet controller 8 in turn, the paper passing mechanism is provided with a conveyor belt 9, and the conveyor belt 9 sends the paper into the creasing part and the marking part, and the creasing part is provided with a creasing part. Marking mold 10, the scribing part is provided with scribing mold 11, one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com