Pressing Device For A Machine Tool For Machining Workpieces Made Of Wood, Plastic And The Like, As Well As A Machine Tool With At Least One Pressure Member

A technology of a pressing device and a machine tool, which is applied to workpiece feeding devices, woodworking safety devices, wood processing appliances, etc., can solve the problems of difficulty in fixing bolts, inability to optimally adjust pressing components, etc., and achieve the effect of simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

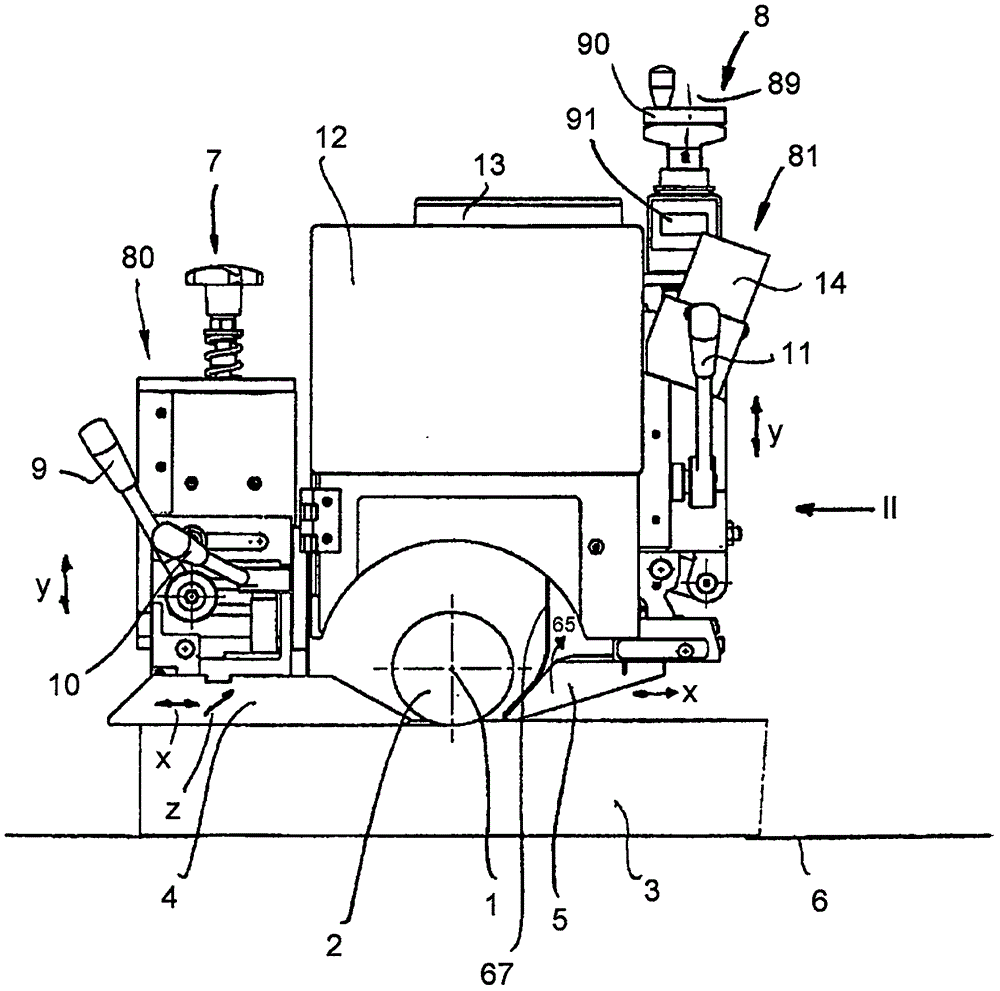

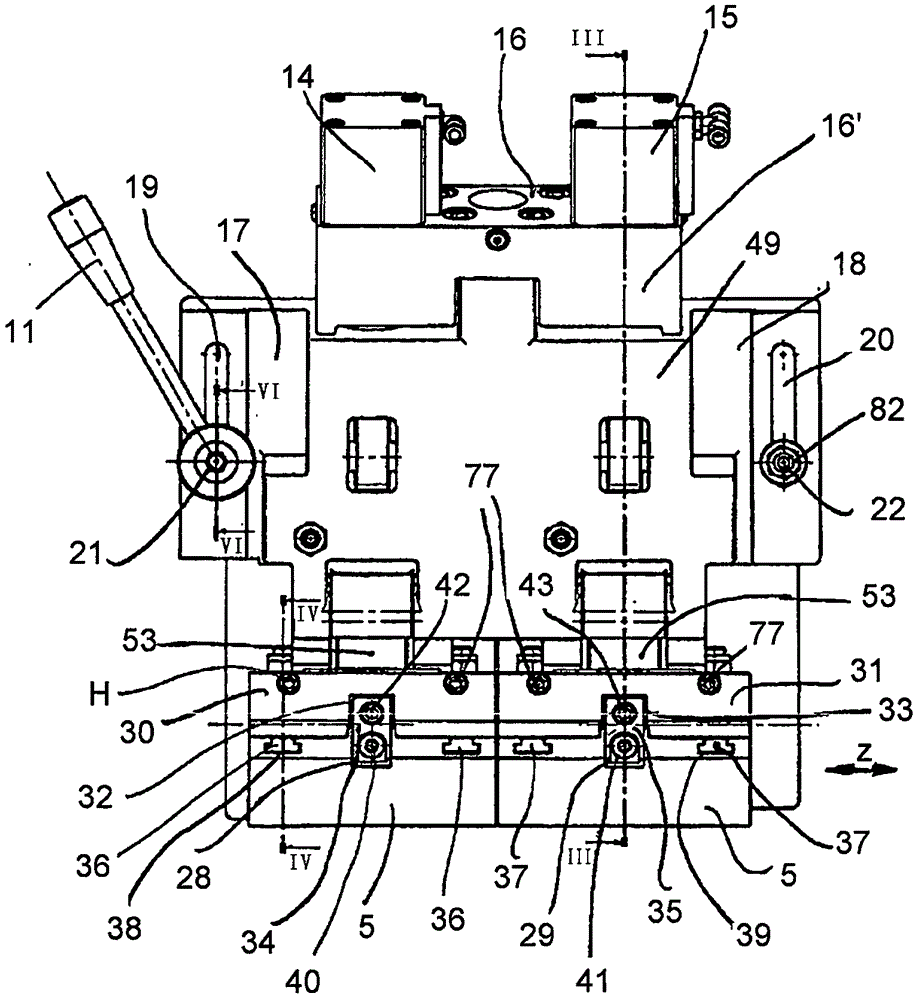

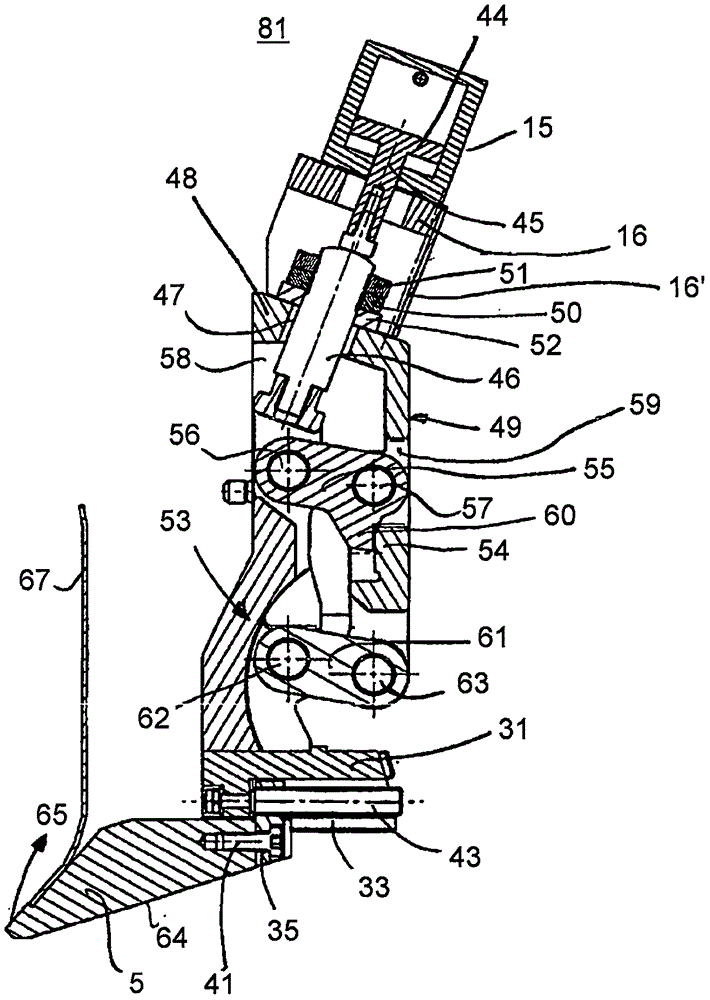

[0039]The pressing device is a part of the lace planer (groove planer), and the side of the workpiece can be processed by the lace planer while it is moving. In general, workpieces made of wood preferably have a rectangular cross section. When such a workpiece passes through the lace planer, the four outer sides of the workpiece are processed by corresponding tools. In the direction of passage, the lace planer successively has a lower spindle, a right spindle, a left spindle and an upper spindle. These spindles are spaced one behind the other at a distance 3 in the direction of passage and carry corresponding machining tools. During passage through the planer, the workpiece is guided along one of its longitudinal sides, preferably the right longitudinal side, on a stop bar. The stop is interrupted in the working area of the tool mounted on the right spindle, so that the right longitudinal side of the workpiece can be machined with this tool when the workpiece passes throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com