Preparation of hierarchical porous materials and hierarchical porous materials

A technology of hierarchical porosity and secondary pores, which is applied in metal material coating process, anodic oxidation, coating, etc., can solve the problems of high cost, difficult to control, single silver pore structure, etc., and achieve low production cost, easy implementation, Effect of controllable pore size and porosity distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

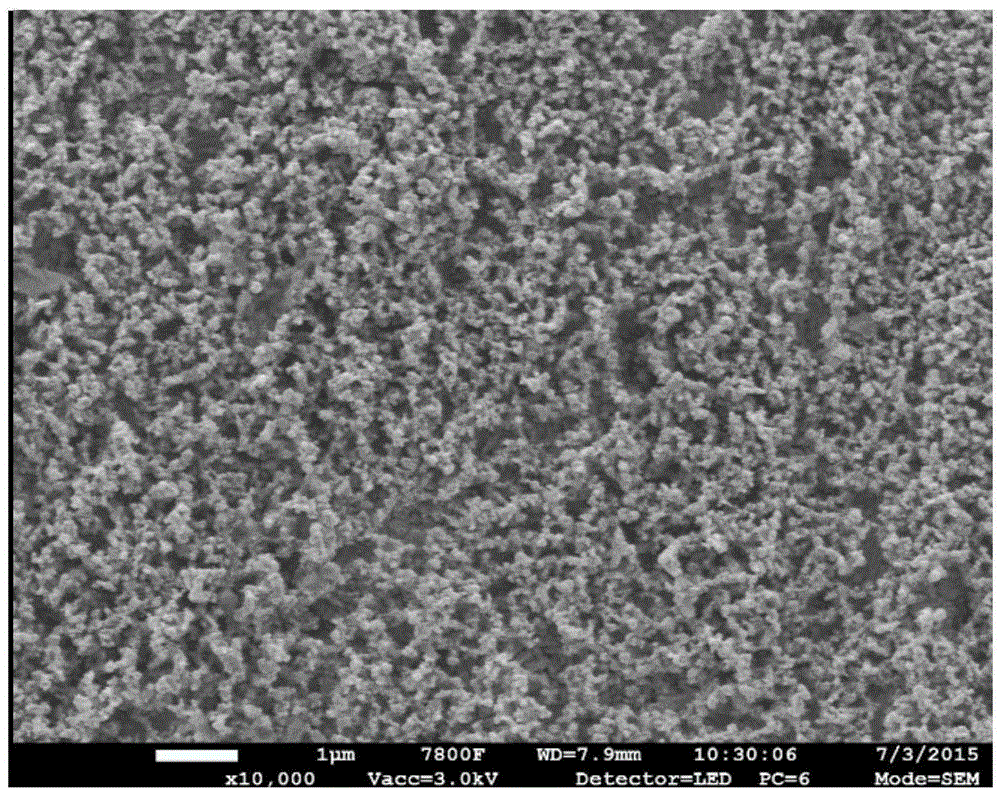

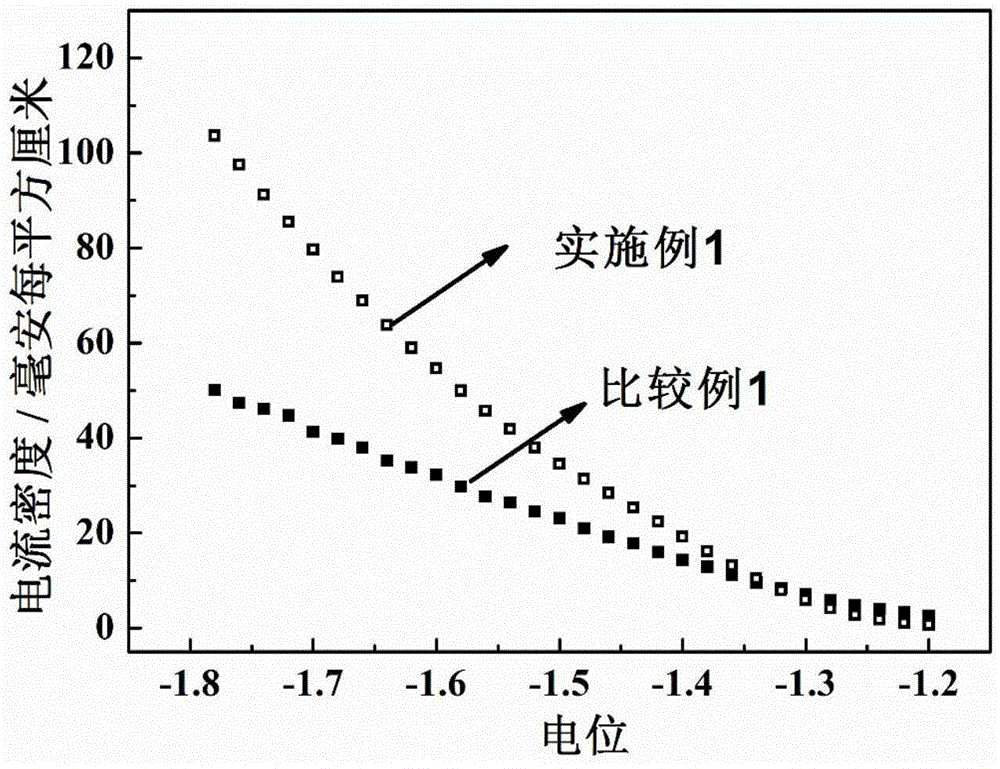

[0024] Embodiment 1: prepare the solution containing the NaOH of 0.1M and use it as electrolyte, zinc sheet is as working electrode, platinum sheet is counter electrode, mercury / mercuric oxide electrode is reference electrode, first in 3V (relative to reversible hydrogen electrode ) under electrochemical oxidation for 30 min, followed by electrochemical reduction at -3 V (relative to the reversible hydrogen electrode) for 10 min to obtain porous zinc.

Embodiment 2

[0025] Embodiment 2: prepare the solution containing the KOH of 0.2M and use it as electrolytic solution, copper wire is as working electrode, and platinum plate is counter electrode, and silver / silver chloride electrode is reference electrode, first at 0V (relative to reversible hydrogen electrode) for 1s, followed by electrochemical reduction at -2V (relative to the reversible hydrogen electrode) for 1s to obtain porous copper.

Embodiment 3

[0026] Embodiment 3: preparation contains the solution of the NaOH of 0.3M and it is used as electrolytic solution, nickel foil is as working electrode, and platinum sheet is counter electrode, and saturated calomel electrode is reference electrode, first at 2.0V (relative to reversible hydrogen electrode ) under electrochemical oxidation treatment for 12h, and then electrochemical reduction at -1.2V (relative to the reversible hydrogen electrode) to obtain porous nickel for 3h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap