A cavity type phase shifter

A phase shifter and cavity technology, applied in waveguide-type devices, antennas, circuits, etc., can solve the problems affecting the performance and deformation of the phase shifter, and avoid blackening of solder joints, low intermodulation, and good welding effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to explain the technical solutions of the embodiments of the present invention more clearly, the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments. Obviously, the embodiments and drawings described below are only a part of the embodiments of the present invention. For those of ordinary skill in the art, without any creative work, everything made based on the technical solutions of the present invention Modifications, improvements, etc. are all included in the protection scope of the present invention.

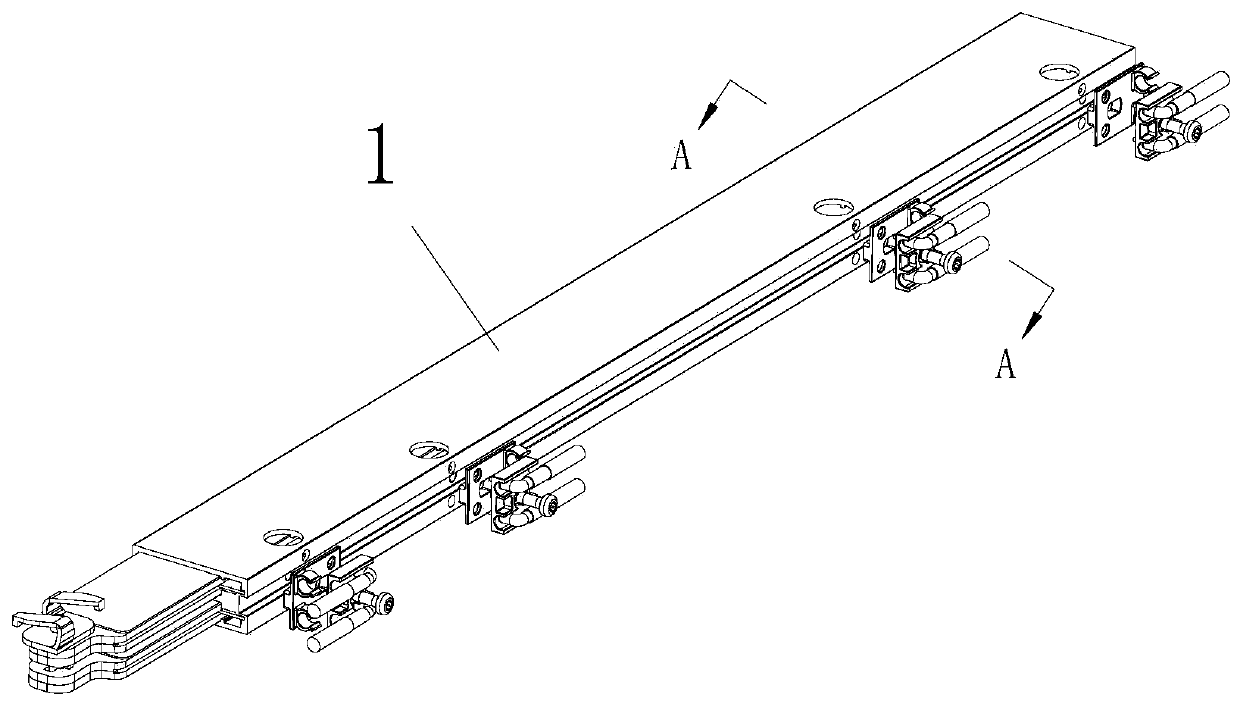

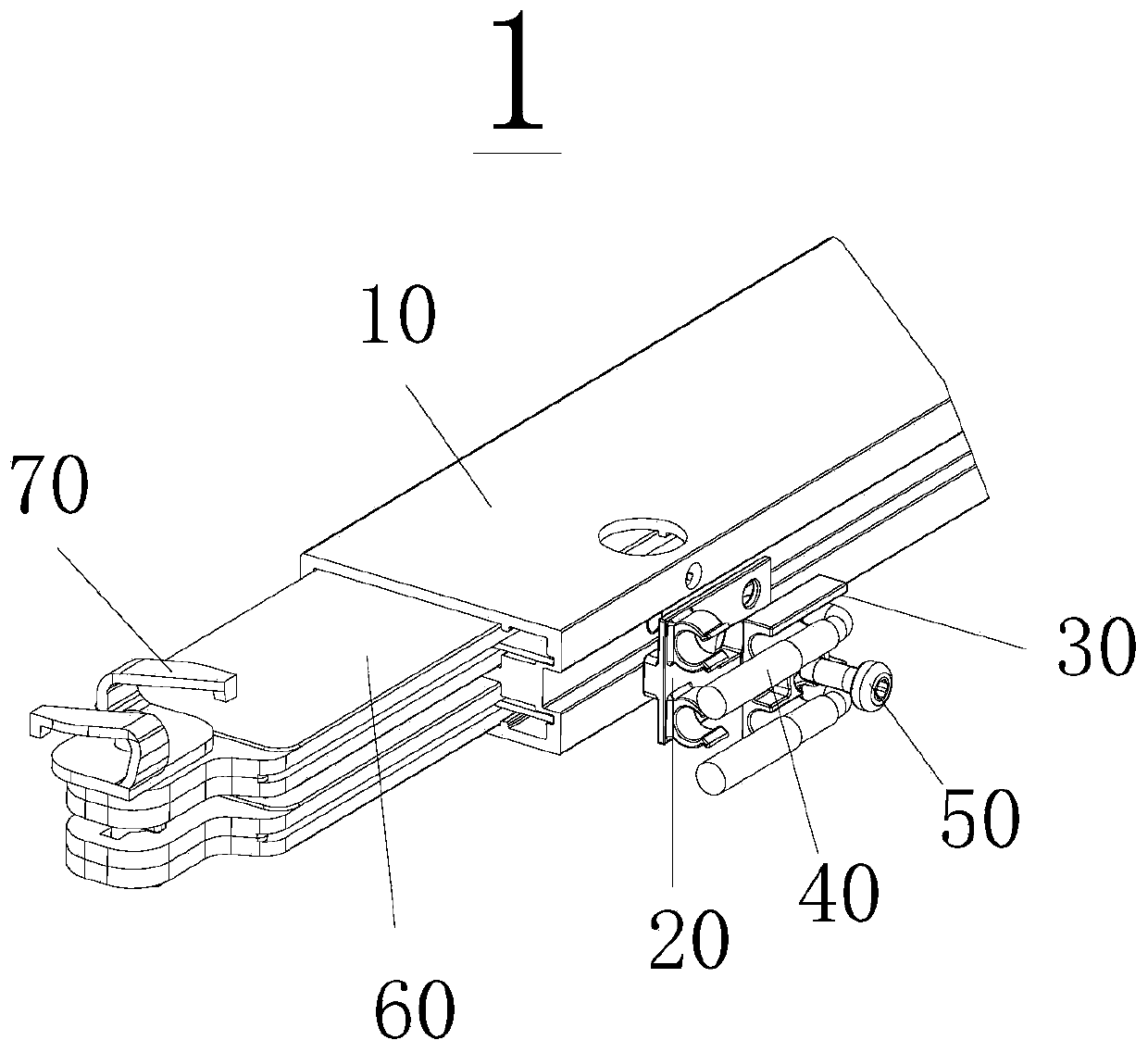

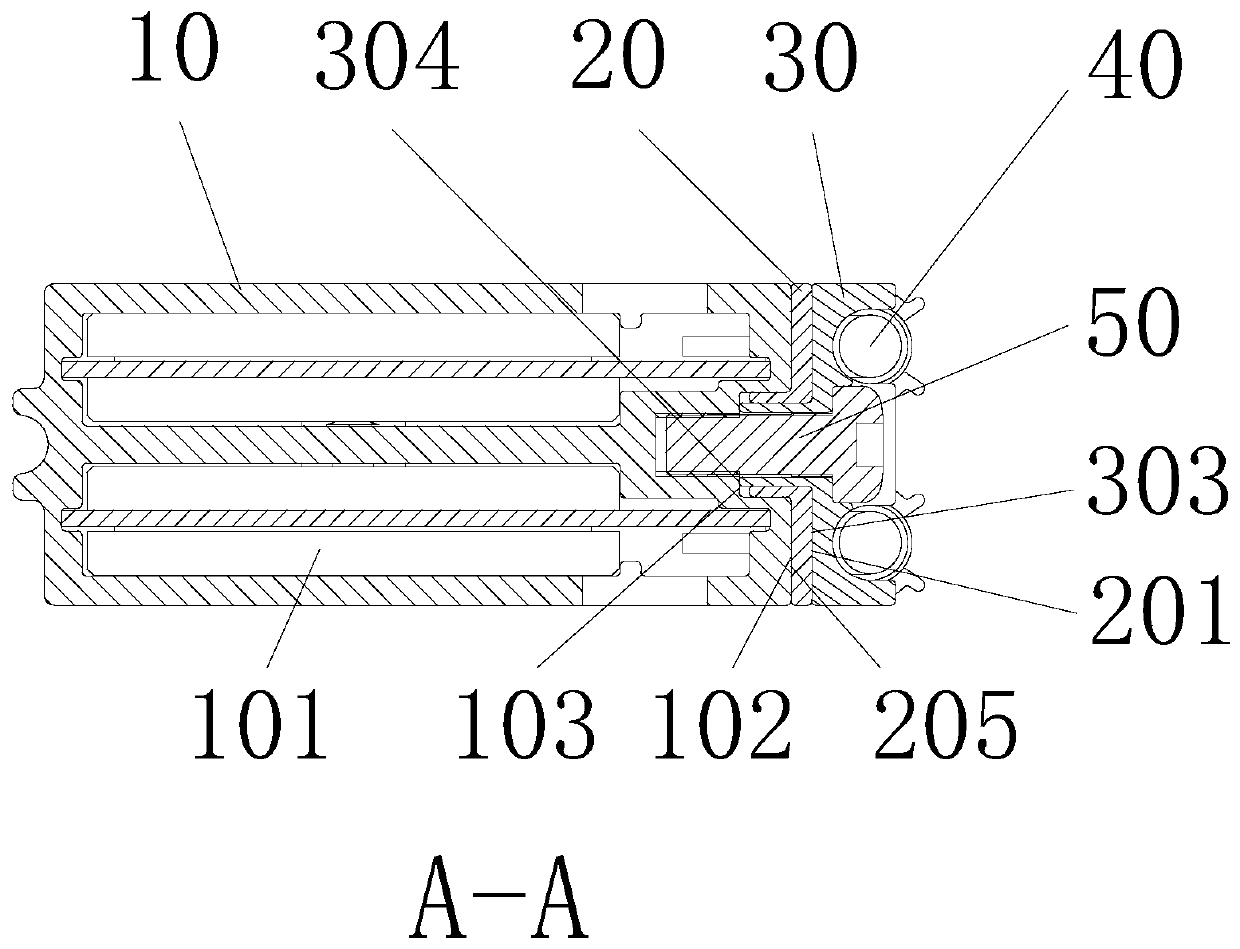

[0051] Such as Figure 1 to Figure 8 As shown, a phase shifter 1 includes a cavity 10, an insulating card 20, a feeder seat 30, a dielectric plate 60, a drive pin 70, and a coaxial cable 40. The corresponding microwave network is set up in specific implementation, and is used where necessary Screw 50 connection.

[0052] The side wall outside the cavity is a concave groove. O...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com