Recycled concrete aggregate screening device

A technology of recycled concrete and screening device, which is applied in the direction of filter screen, solid separation, grille, etc. It can solve problems such as difficult to clean, aggregate stuck, and affect the efficiency of aggregate screening, so as to achieve labor-saving operation and good aesthetics Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

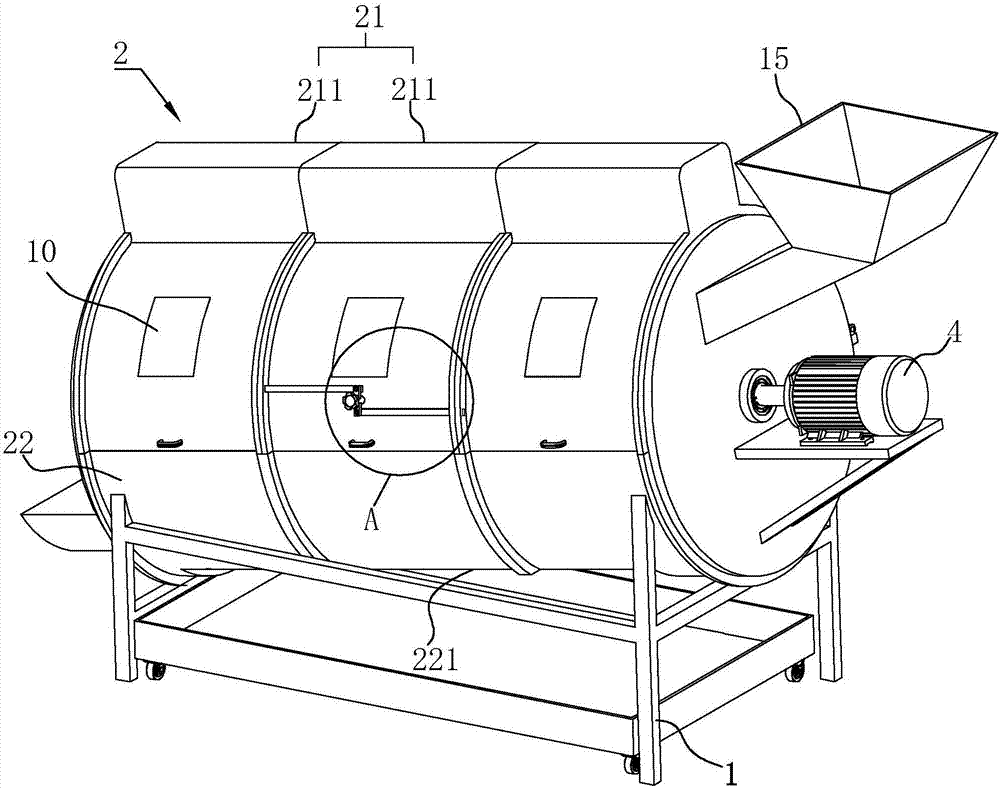

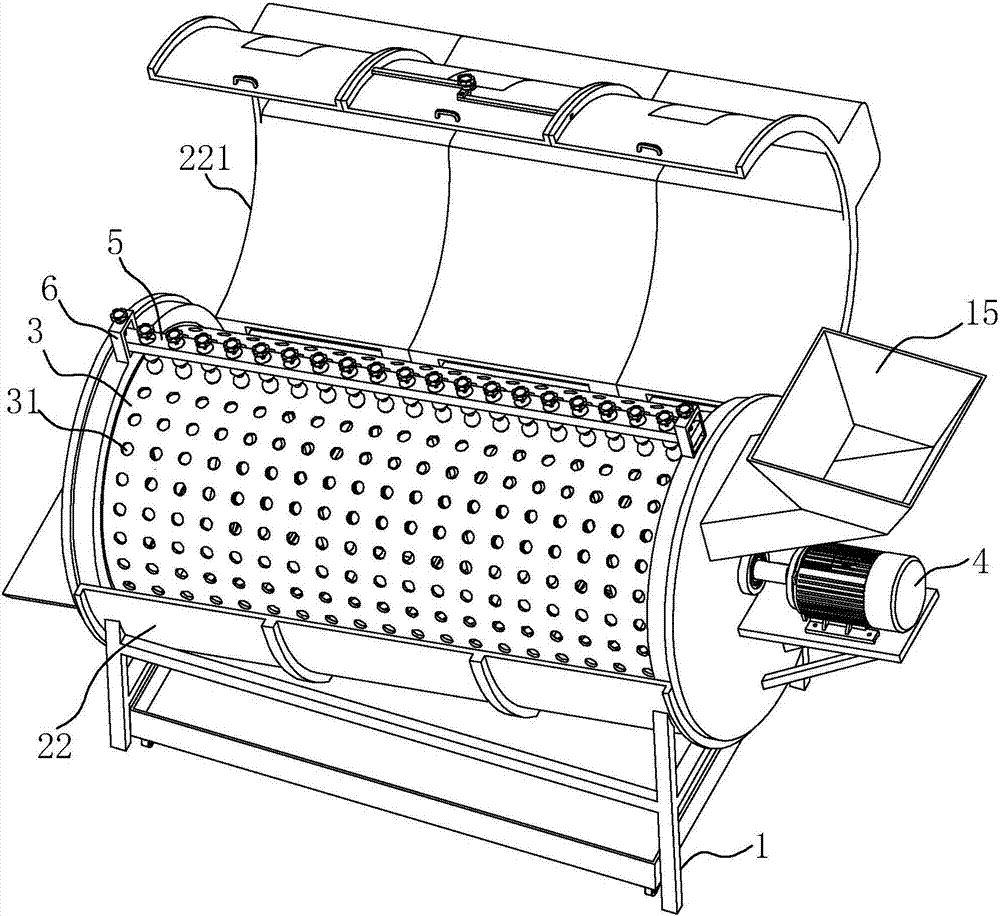

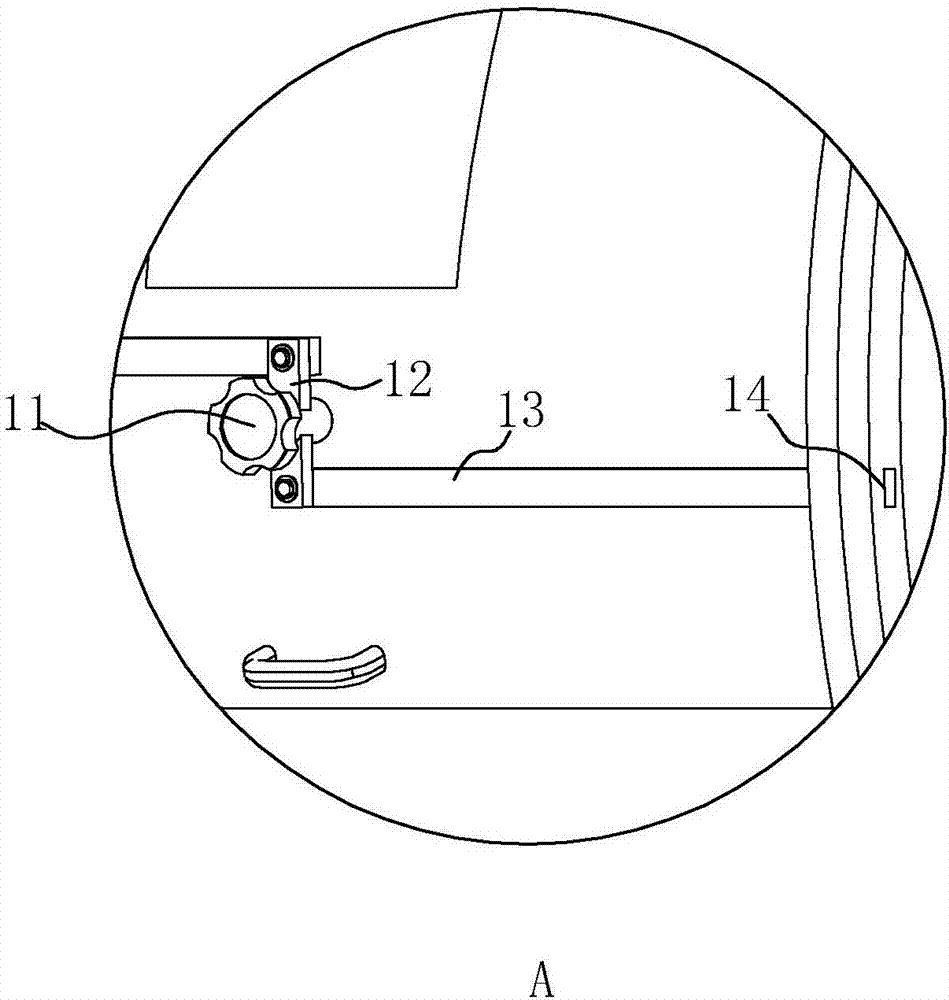

[0037] Embodiment 1: A kind of recycled concrete aggregate screening device, such as figure 1 and figure 2 As shown, it includes a support frame 1 and a body. The body includes a housing 2 and is connected with a sieve body 3 in a tilted rotation in the housing 2, and a feed hopper 15 communicated with the sieve body 3 is provided on one end of the housing 2. There are sieve holes 31 evenly distributed on the sieve body 3, and a drive mechanism for driving its rotation is provided on the sieve body 3, the drive mechanism is a motor 4 and a reducer, and the housing 2 includes a top shell 21 and a bottom shell 22 , and a material leakage port 221 is opened on the upper bottom of the bottom shell 22, so that the aggregate is poured from the feed hopper 15 into the rotating sieve body 3, and the aggregate with smaller particles can fall from the sieve hole 31 and Leaks out from the leakage port 221, and the aggregate with larger particles rolls to the lowest point of the sieve b...

Embodiment 2

[0042] Embodiment 2: A kind of recycled concrete aggregate screening device, such as Figure 7 and Figure 8 As shown, the difference between it and Embodiment 1 lies in the difference of the driving member. The driving member includes a stud 8 that penetrates in the chute 61 and abuts against the mounting bar 5 . The end of the mounting bar 5 away from the stud 8 and the chute The second spring 9 is arranged between the 61 inner walls, so only the stud 8 needs to be rotated, and the mounting bar 5 is pushed to adjust the position by means of the stud 8. When the stud 8 is rotated and moved inwardly, the second spring 9 is compressed, and the stud 8 is turned over. When the post 8 moves back, the mounting strip 5 will recover under the action of the second spring 9, the structure is simple, and the threaded stud 8 also has an axial anti-reverse effect, making the adjustment of the position of the mounting strip 5 more stable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com