A kind of ultra-high temperature and high pressure resistant air felt with high air permeability and preparation method thereof

A technology of ultra-high temperature and air felt, which is applied in textiles, papermaking, non-woven fabrics, etc. It can solve the problems of affecting the quality of composite materials, shedding, and poor air permeability of air felt, and achieves excellent air permeability at room temperature and air conduction. The effect of outstanding ability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

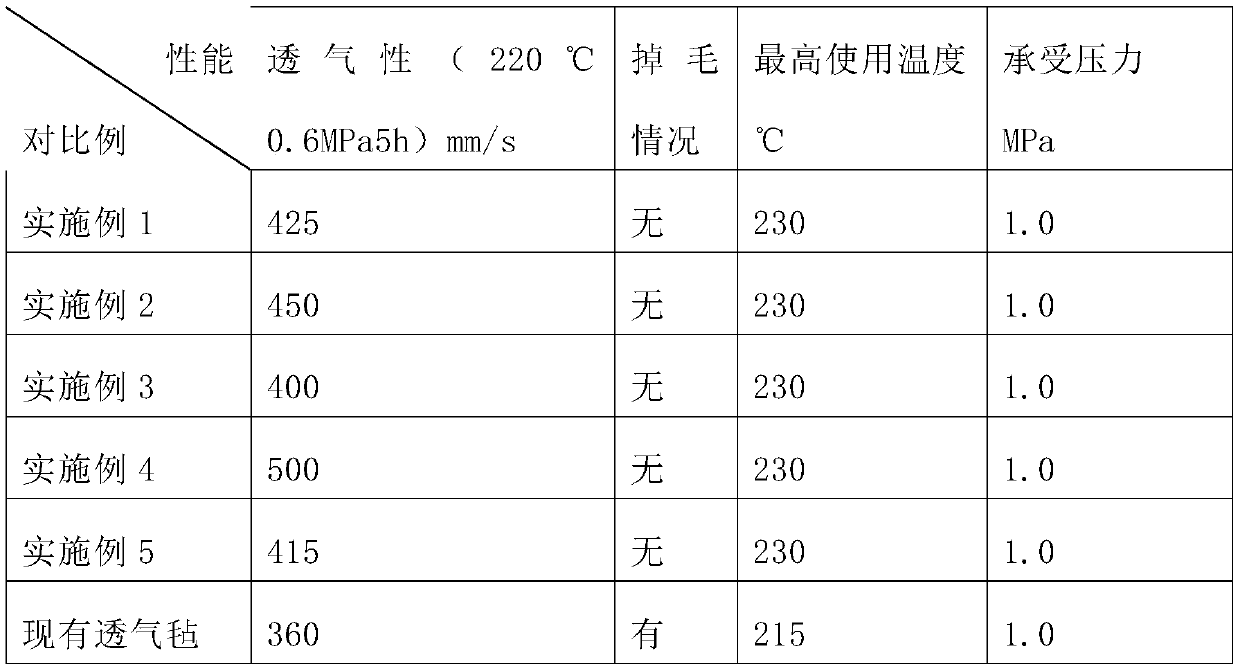

Examples

Embodiment 1

[0028] An air felt with ultra-high temperature and high pressure resistance and high air permeability is prepared by needle punching mixed with 70% modified nylon 66 staple fiber and 30% polyester staple fiber. The modified nylon 66 short fiber is prepared by twin-screw blending, extruding, granulating, and spinning after nylon 66 chip, heat stabilizer, and antioxidant in a certain ratio of 99:0.5:0.5. The specific preparation method of this embodiment comprises the following steps:

[0029] (1) After unpacking the modified nylon 66 staple fiber and polyester staple fiber, they were manually added to the bins of two unpacking machines. The polyester staple fiber was prepared by melt direct spinning, and the modified nylon 66 staple fiber and polyester staple fiber were The specification of staple fiber is 3dtex×30mm. The bale opener is mixed according to the set weight percentage ratio of 7:3 and then added to the pre-opener for preliminary loosening. The speed of the corner ...

Embodiment 2

[0036] An air felt with ultra-high temperature and high pressure resistance and high air permeability is prepared by needle punching mixed with 80% modified nylon 66 staple fiber and 20% polyester staple fiber. The modified nylon 66 staple fiber is prepared by twin-screw blending, extruding, granulating, and spinning after nylon 66 chip, heat stabilizer, and antioxidant in a certain ratio of 97:2:1. The specific preparation method of this embodiment comprises the following steps:

[0037] (1) After unpacking the modified nylon 66 staple fiber and polyester staple fiber, they were manually added to the bins of two unpacking machines. The polyester staple fiber was prepared by melt direct spinning, and the modified nylon 66 staple fiber and polyester staple fiber were The specification of staple fiber is 12dtex×45mm. The unpacking machine is mixed according to the set weight percentage ratio of 8:2 and then added to the pre-opening machine for preliminary loosening. The speed o...

Embodiment 3

[0044] An air felt with ultra-high temperature and high pressure resistance and high air permeability is prepared by needle punching mixed with 50% modified nylon 66 staple fiber and 50% polyester staple fiber. The modified nylon 66 short fiber is prepared by twin-screw blending, extruding, granulating, and spinning after nylon 66 chip, heat stabilizer, and antioxidant in a certain ratio of 97:0.5:2.5. The specific preparation method of this embodiment comprises the following steps:

[0045] (1) After unpacking the modified nylon 66 staple fiber and polyester staple fiber, they were manually added to the bins of two unpacking machines. The polyester staple fiber was prepared by melt direct spinning, and the modified nylon 66 staple fiber and polyester staple fiber were The specification of staple fiber is 20dtex×65mm. The unpacking machine is mixed according to the set weight percentage ratio of 5:5 and then added to the pre-opening machine for initial loosening. The speed of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| service temperature | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com