Vertical shaft difference freezing device

A differential freezing and shaft technology, applied in shaft equipment, sinking, mining equipment, etc., can solve the problems of long freezing period of rock and soil, affecting the progress of the project, etc., and achieve the goal of improving the effective utilization rate, prolonging the residence time, and improving the freezing efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

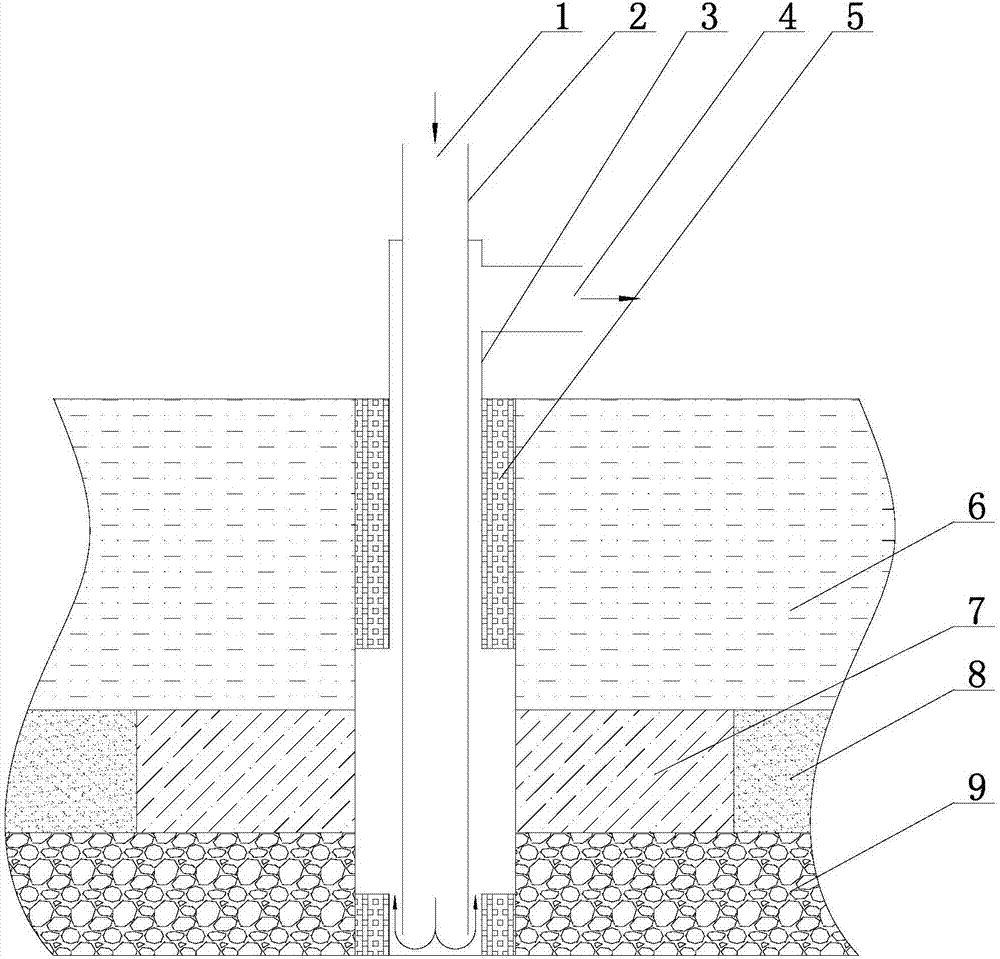

[0018] Such as figure 1 As shown, the shaft differential freezing device of the present invention comprises an inner tube 2 and an outer tube 4, and the outer tube 4 is sleeved outside the inner tube 2, increasing the outer diameter of the middle part of the outer tube 4, so that the outer diameter of the middle part of the outer tube 4 The outer diameter is greater than the outer diameter of its upper and lower parts, and the outer circumference of the upper and lower parts of the outer tube 4 (i.e. the small part of the outer tube 4 outer diameter) is wrapped with an insulating layer 5, and the outer diameter of the insulating layer 5 is the same as the outer diameter of the outer tube 4 (i.e. Outer tube 4 outside diameter small part) has the same outer diameter; The top of inner tube 2 has freezing liquid liquid inlet 1, and its bottom is open and height is h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com