Marine screw-type liquid nitrogen freezing equipment

A liquid nitrogen freezing and spiral technology, applied in auxiliary equipment, hull ventilation/heating/cooling, preservation of meat/fish by freezing/cooling, etc., to achieve high space utilization, reduce cold energy waste, and improve utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The following are specific embodiments of the invention and in conjunction with the accompanying drawings, the technical solution of the invention is further described, but the invention is not limited to these embodiments.

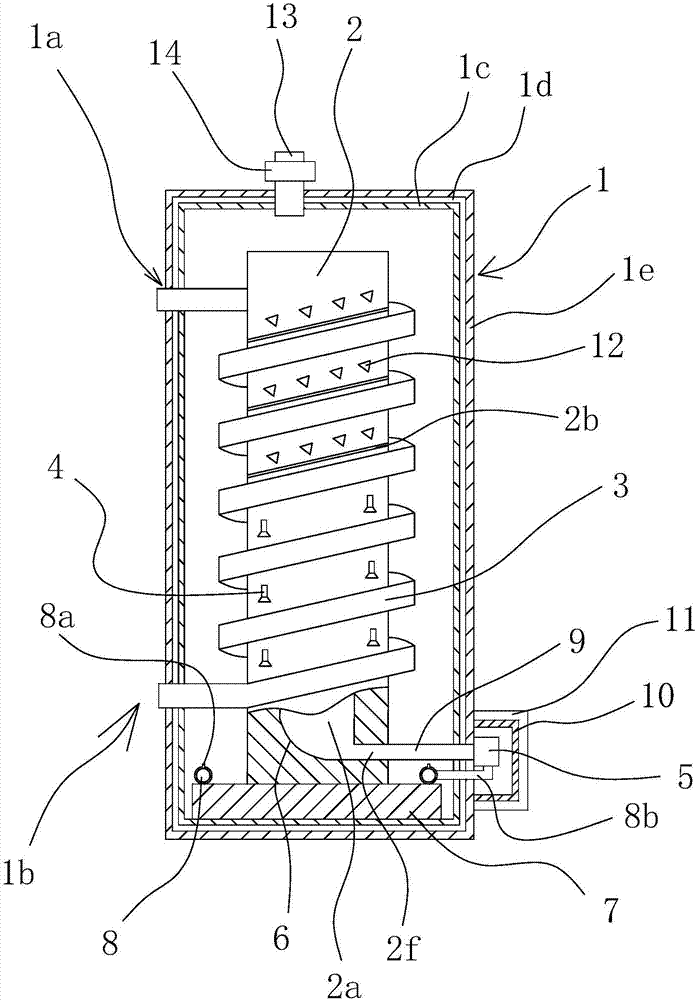

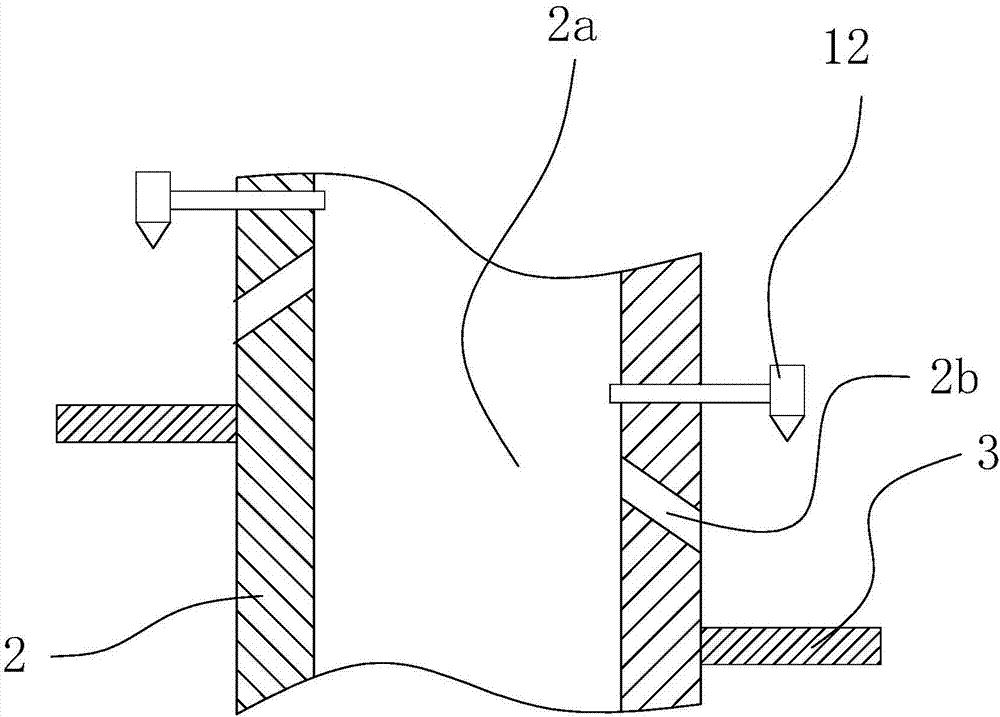

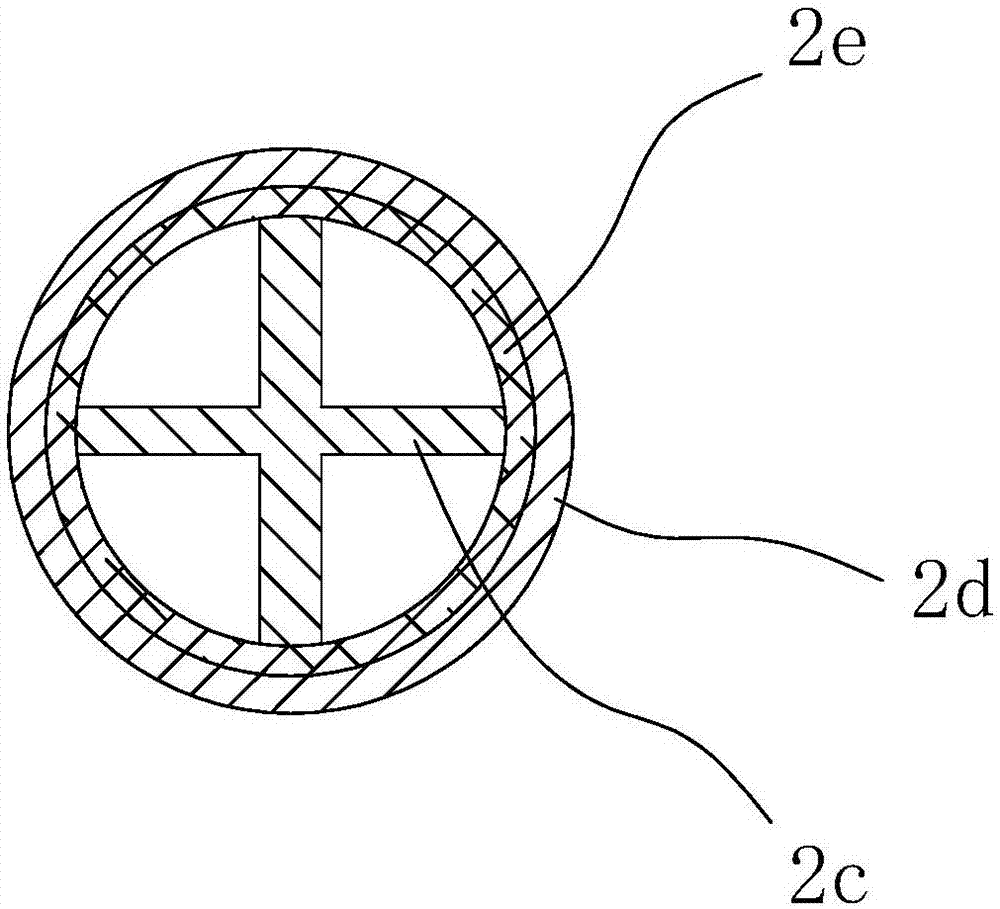

[0038]Such as Figure 1-3 As shown, a marine spiral liquid nitrogen freezing equipment includes a freezing chamber 1, a pillar 2 arranged in the freezing chamber 1, a conveying mesh belt 3 spirally arranged along the axial direction of the pillar 2, and the upper end of the freezing chamber 1 There is a feed port 1a, the lower end has a discharge port 1b, the upper end of the conveying mesh belt 3 communicates with the feed port 1a, and the lower end communicates with the discharge port 1b, the pillar 2 has an inner cavity 2a, and the pillar 2 It includes a pre-cooling section at the upper end and a freezing section at the lower end, and several liquid nitrogen spray nozzles 4 are arranged along the conveying mesh belt 3 on the freezing section, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com