Quick-freezing device

A quick-freezing device and freezing chamber technology, which is applied to household refrigeration devices, coolers, lighting and heating equipment, etc., can solve the problems of increased operating costs and material costs, loss of freezing medium, difficulty in maintaining freezing efficiency, etc., and achieve reduction of freezing medium The effect of loss, reduction of escape, and improvement of freezing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

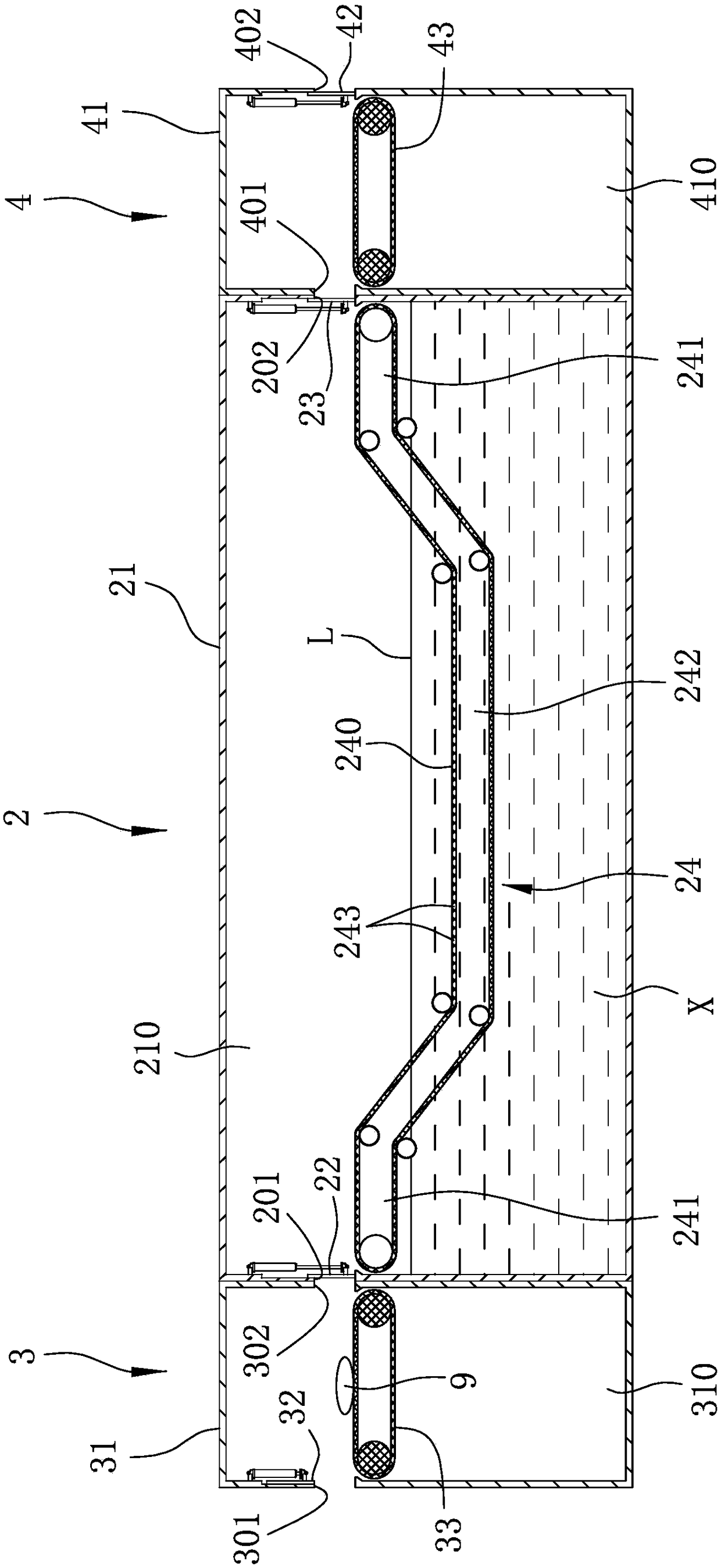

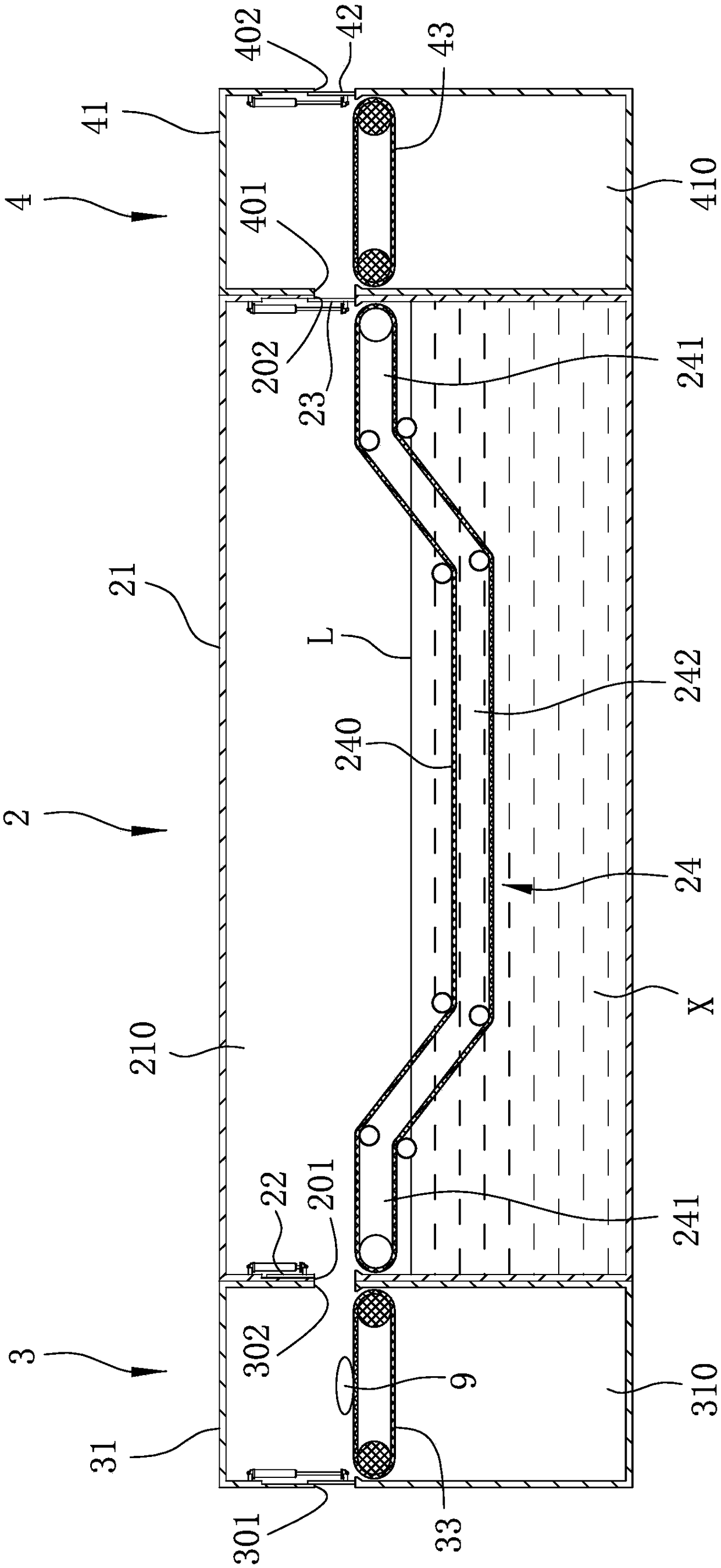

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

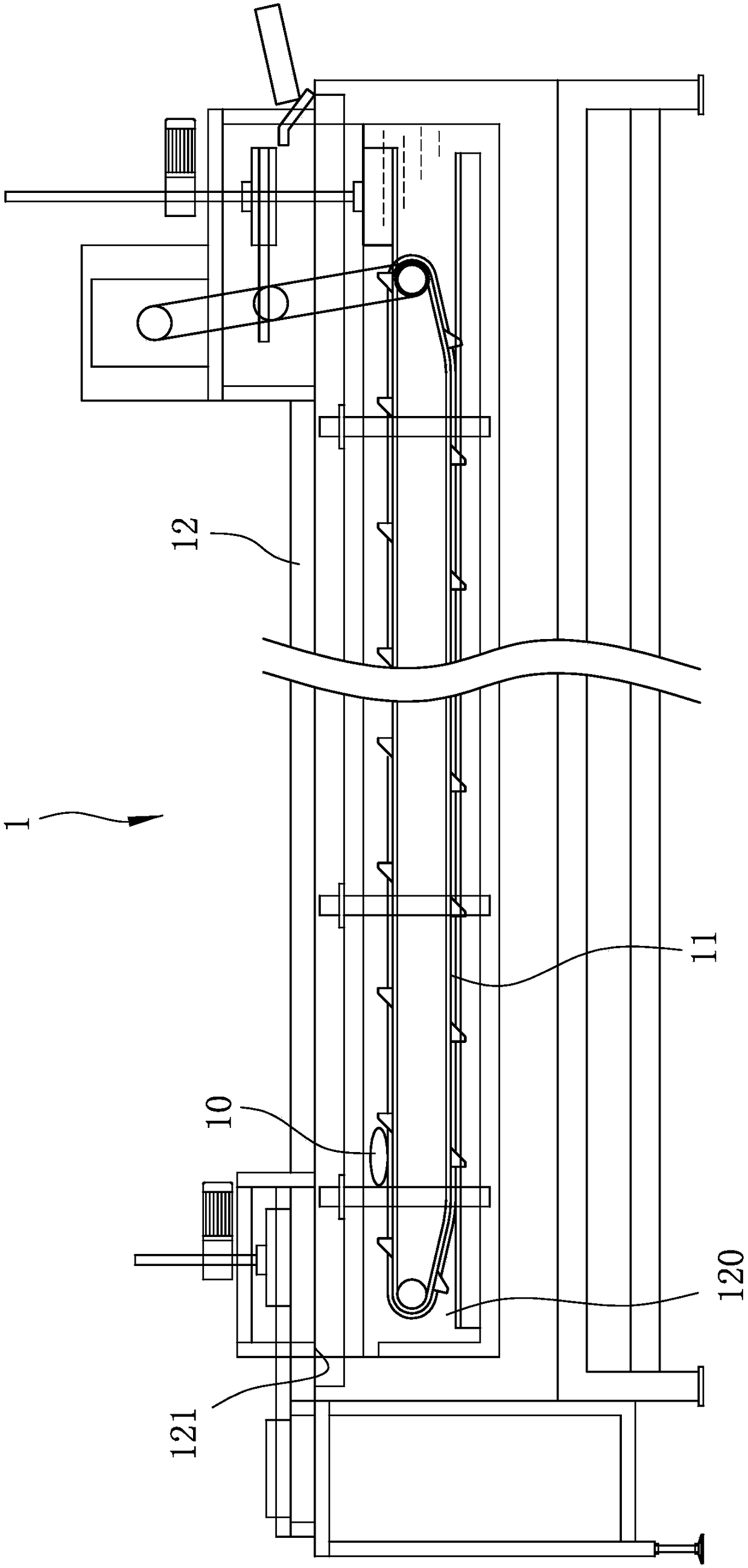

[0023] refer to figure 2 , a first embodiment of the quick-freezing device of the present invention is suitable for freezing a plurality of objects to be frozen 9, and includes a main bucket unit 2, a first isolation unit 3 connected to the upstream of the main bucket unit 2, and a A second isolation unit 4 downstream of the main barrel unit 2 . It should be explained first that in this embodiment, the process of freezing a single object 9 at a time is taken as an example. When the first embodiment is actually used, a plurality of objects 9 can be frozen in the same way.

[0024] The main tub unit 2 includes a body 21 surrounding a freezing chamber 210 with an upstream port 201 and a downstream port 202, an upstream gate 22 switchably arranged at the upstream port 201, a switchably provided at the The downstream gate 23 of the downstream port 202 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com