Thickness-controllable high-performance graphene film and preparation method thereof

A graphene film and graphene technology, applied in graphene, chemical instruments and methods, inorganic chemistry, etc., can solve problems such as phonon scattering, disadvantages, and difficulty in application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

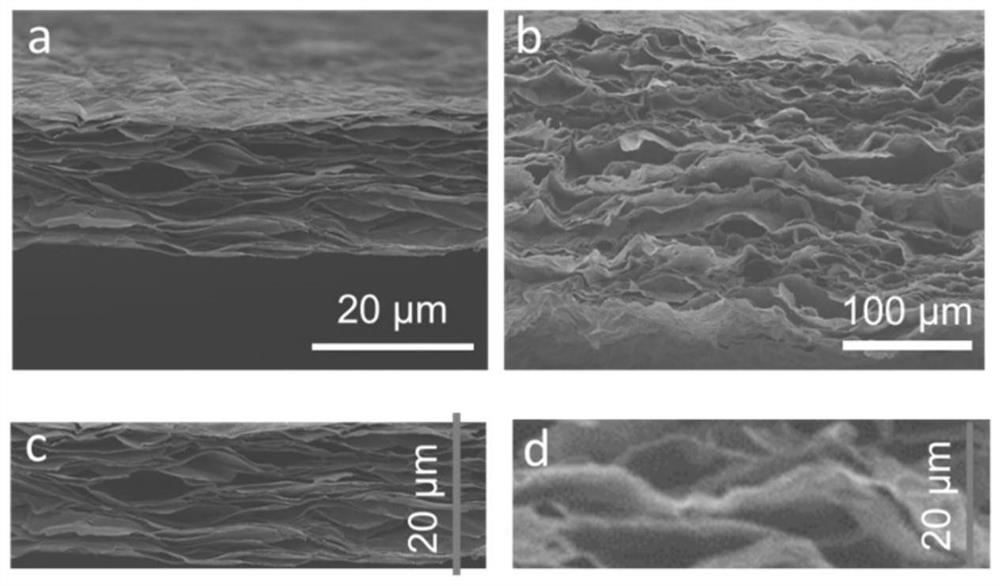

[0031] Embodiment 1: Structural unit research

[0032] (1) Evenly disperse graphene oxide and graphitizable polymer PAN in DMF, wherein the mass ratio of graphene oxide and graphitizable polymer PAN is 1:1; the mixed liquid-solid content is 1.02%.

[0033] (2) The mixture of graphene oxide and graphitizable polymer PAN is sprayed with a 50nm submicron film by means of centrifugal spraying. On the submicron membrane, a layer of 3nm polyvinyl alcohol (PVA) polymer was centrifugally sprayed. By spraying while drying (the drying temperature is 60°C), the submicron film and polyvinyl alcohol (PVA) layer are sprayed layer by layer to obtain a graphene film composite film with a thickness of 3 μm. After the membrane was removed, it was pre-oxidized at 270°C for 2 hours.

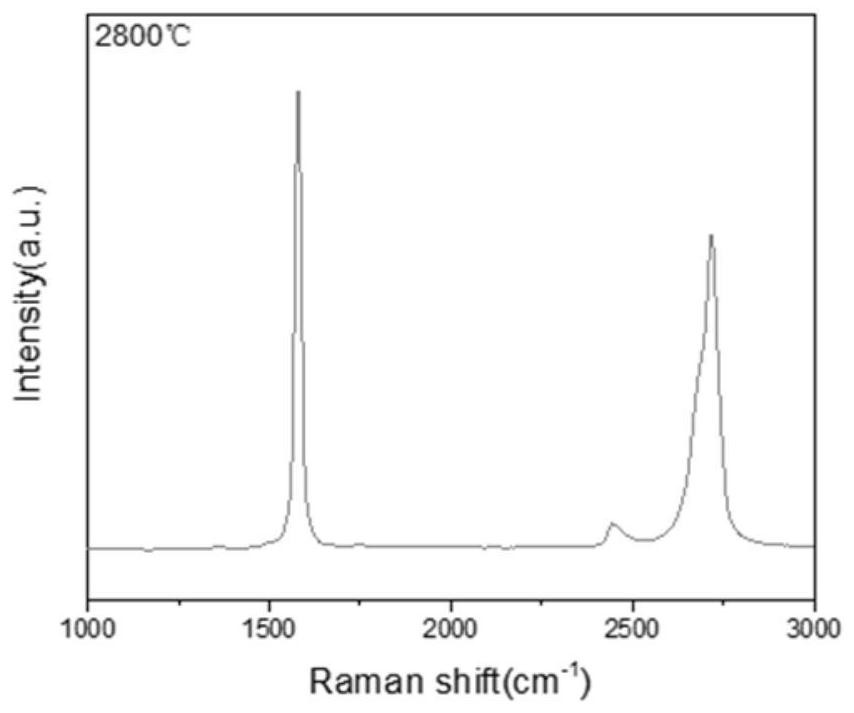

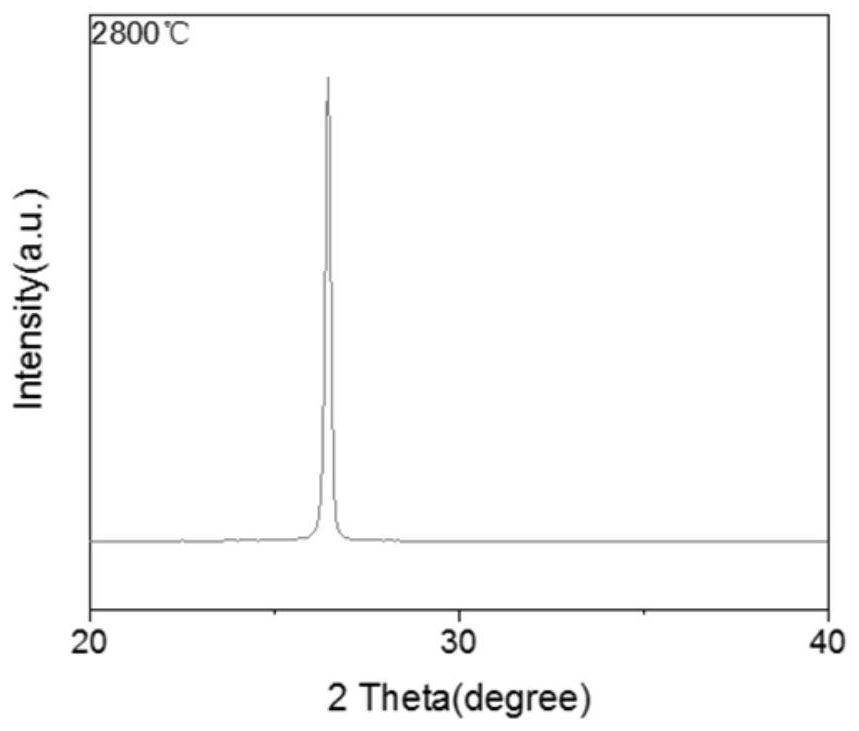

[0034] (3) A 1 μm high-performance graphene film was obtained after a 3 μm thick film was processed at a high temperature of 2800 ° C.

[0035] Through such layer-by-layer assembly and high temperature treatment ...

Embodiment 2

[0036] Embodiment 2: structural unit research

[0037] (1) Evenly dispersing graphene oxide and graphitizable polymer PAA in water, wherein the mass ratio of graphene oxide and graphitizable polymer PAN is 2 / 3; the solid content of the mixed liquid is 1.5%;

[0038] (2) The graphene oxide and graphitizable polymer PAA mixture is sprayed with a layer of 100nm submicron film by means of centrifugal spraying. On the submicron membrane, a layer of 5nm polyvinyl alcohol (PVA) polymer was centrifugally sprayed. By spraying while drying (the drying temperature is 60°C), the submicron film and polyvinyl alcohol (PVA) layer are sprayed layer by layer to obtain a graphene film composite film with a thickness of about 15 μm.

[0039] (3) Put the 15 μm composite film into a vacuum oven for thermal imidization, and treat it in the vacuum oven at 250° C. for 2 hours. A graphene-PI composite film is obtained, and the composite film is processed at a high temperature of 2800°C to obtain a h...

Embodiment 3

[0041] Embodiment 3: structural unit research

[0042] (1) Evenly dispersing graphene oxide and graphitizable polymer lignin in water, wherein the mass ratio of graphene oxide to graphitizable polymer PAN is 1.5; the solid content of the mixed liquid is 1.48%;

[0043] (2) The mixture of graphene oxide and graphitizable polymer lignin is sprayed with a layer of 200nm submicron film by means of centrifugal spraying. On the submicron membrane, a layer of 10nm polyvinyl alcohol (PVA) polymer was centrifugally sprayed. By spraying while drying (the drying temperature is 60° C.), the submicron film and polyvinyl alcohol (PVA) layer are sprayed layer by layer to obtain a graphene film composite film with a thickness of about 30 μm.

[0044] (3) Put the 30 μm composite film into an oven and dry at 60° C. for 12 hours. Graphene-lignin composite film, the composite film is processed at a high temperature of 2800 ° C to obtain a high-performance graphene film of about 20 μm.

[0045]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com