Method and apparatus for providing aluminum alloy meltwater

A technology of aluminum alloy and molten liquid, which is applied to equipment for feeding molten metal into casting molds, casting melt containers, metal processing equipment, etc., can solve the problems of reducing casting yield, difficult to maintain melting temperature, power consumption, etc., Achieve the effect of improving yield, reducing heat dissipation to the outside world, and saving electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention is described in detail below in conjunction with accompanying drawing and embodiment:

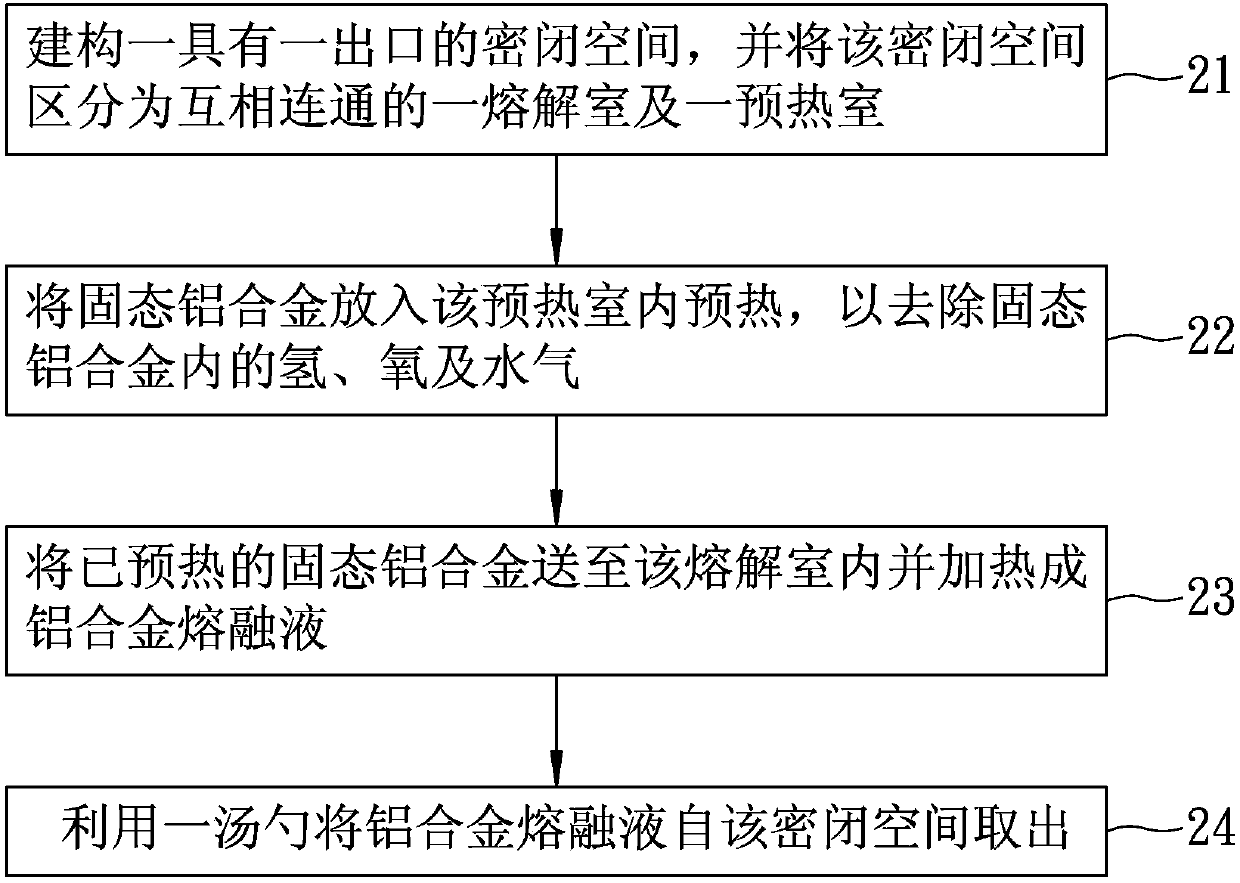

[0042] refer to figure 2 , a preferred embodiment of the method for supplying molten aluminum alloy in the present invention comprises the following steps:

[0043] Step 21: Construct a closed space with an outlet, and divide the closed space into a melting chamber and a preheating chamber connected to each other, and the preheating chamber is located above the melting chamber.

[0044] Step 22: Preheating the solid aluminum alloy in the preheating chamber to remove hydrogen, oxygen and moisture in the solid aluminum alloy. In this preferred embodiment, the solid aluminum alloy is aluminum grains of aluminum alloys, but it can also be other smaller volumes of aluminum alloys, such as aluminum shavings of aluminum alloys. The temperature in the preheating chamber is about 450°C to 550°C. The heat energy comes from the high heat generated in the melting chamber...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com