Method and device for freezing dough assisted by frequency conversion ultrasound

A technology of frozen dough and frequency conversion ultrasound, which is applied in food science, food preservation, application, etc. It can solve the problems of unfavorable industrial mass production, poor taste, and expensive equipment, so as to ensure the quality of frozen products, and the quality of products is stable and controllable. The effect of improving the freezing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

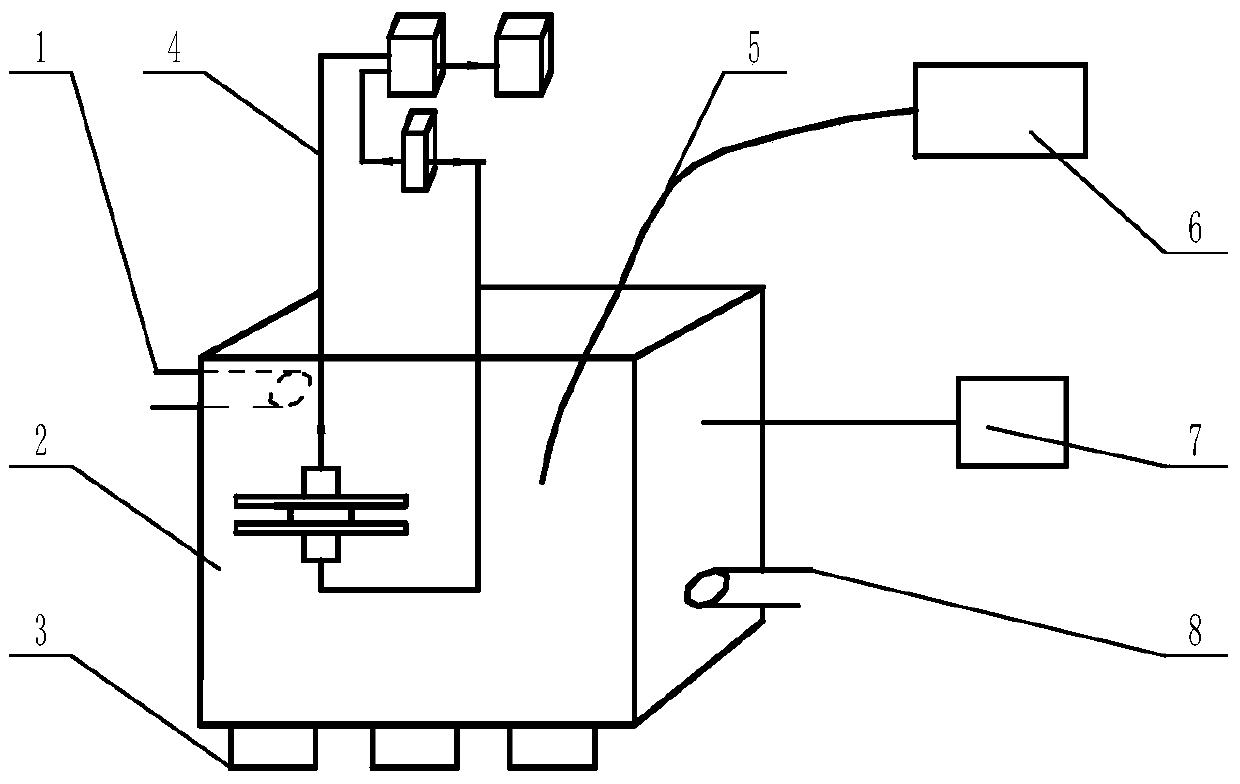

[0040] The device of the frequency conversion ultrasonic assisted freezing dough of the present embodiment is as figure 1 As shown, it includes an ultrasonic auxiliary freezing tank and an ultrasonic attenuation detector 4; Panel 7 ; the ultrasonic treatment chamber 2 is provided with a cooling liquid circulation outlet 1 and a cooling liquid circulation inlet 8 . The acoustic wave transducer is arranged under the ultrasonic treatment chamber and connected with the ultrasonic control panel; the thermocouple with armored head is connected with the temperature recorder.

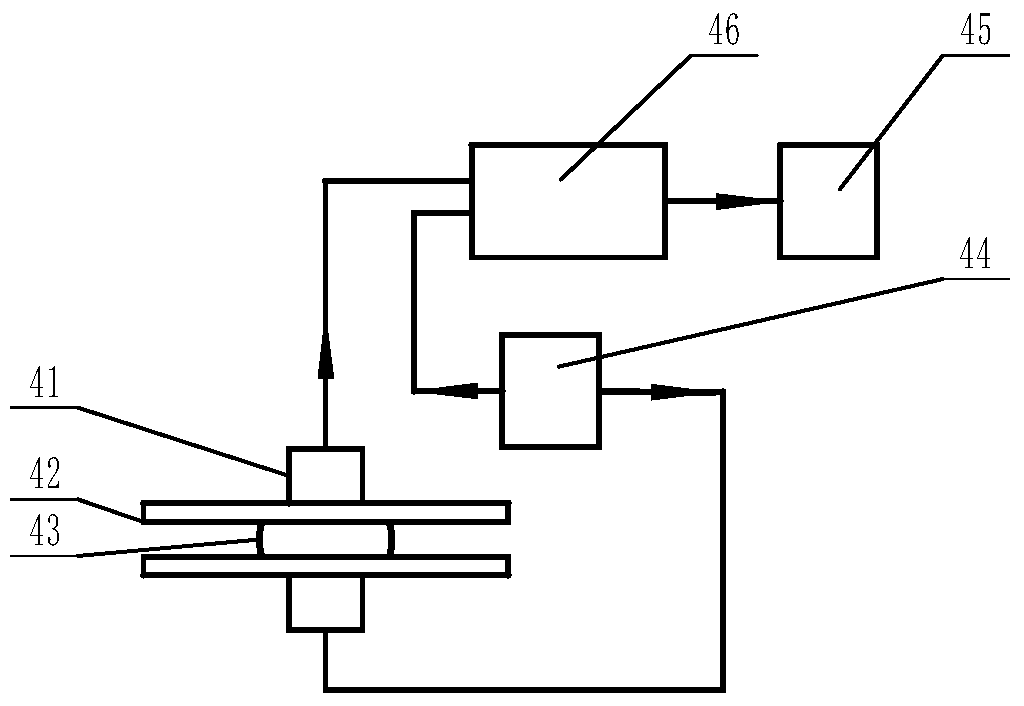

[0041] Such as figure 2 As shown, the ultrasonic attenuation detector includes an acrylic tray 42, an ultrasonic transducer 41, a pulse generator 44, a computer 45, and a signal receiver 46; between the lower parts; the ultrasonic transducers are two, respectively located above the top of the acrylic tray and below the bottom of the acrylic tray; the pulse generator is connected with one of the ultrasonic tr...

Embodiment 2

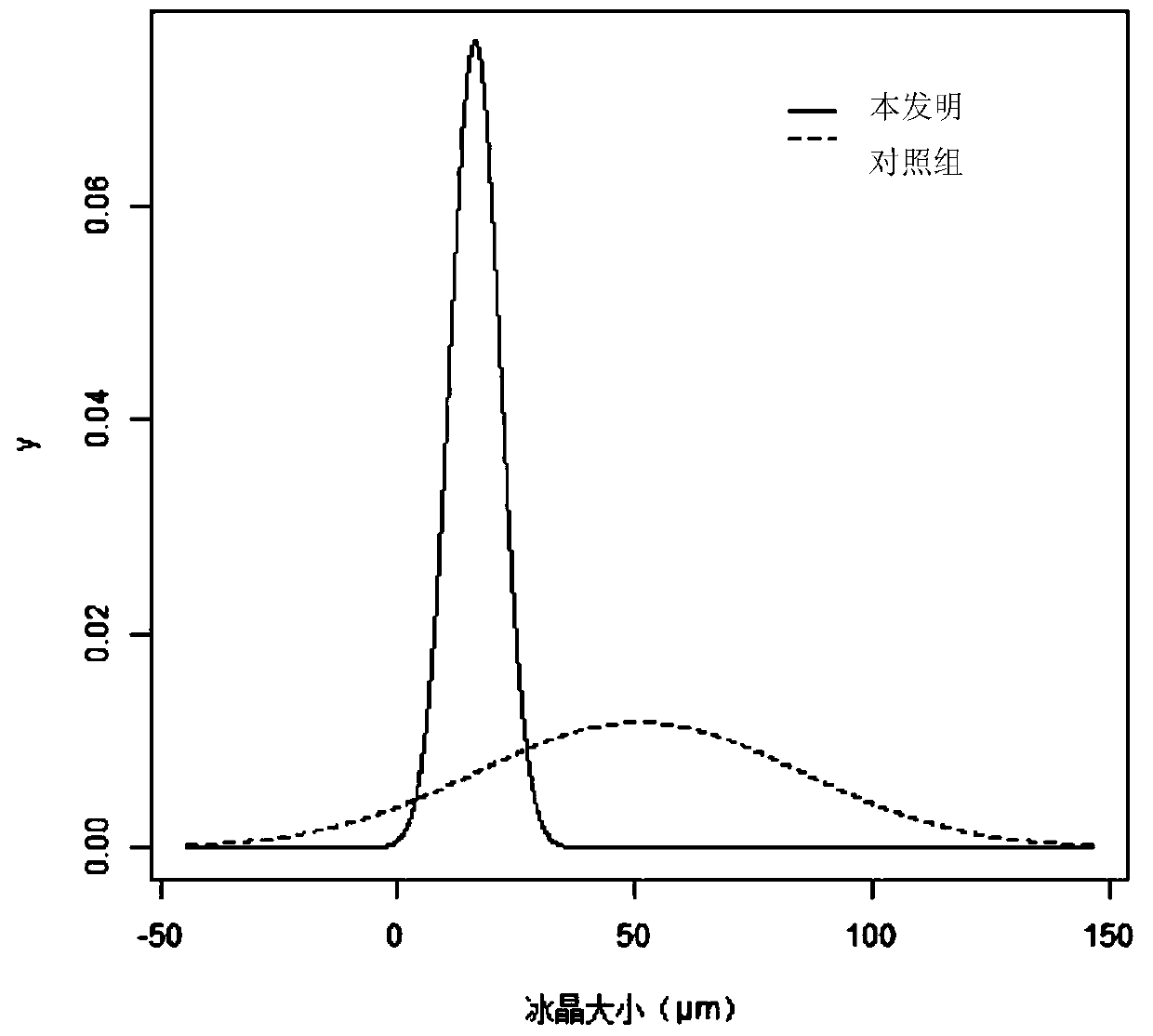

[0061] Take raw materials: 500g of flour, 10g of salt, 20g of yeast, and 300g of water are put into the blender evenly. Then put the dough into an 80cm*60cm*30cm ultrasonic-assisted freezing device, let it stand, and wait for the dough to proof. At the same time, connect the outlet and inlet of the refrigerant circulation to the refrigerator model HRS-140F, the temperature of the facility is -23°C, and turn on the equipment for precooling. Use 50kHz, 700W ultrasonic waves for detection, when Δα reaches 2, open the refrigerant circulation outlet and inlet, and the flow rate is 6L / min. When the temperature of the center of the dough reaches -1°C, turn on the 80kHz, 1000W ultrasonic wave, with 10s as a working cycle, the ultrasonic wave works for 3s and stops for 7s. When the temperature of the center of the dough reaches -4°C, the ultrasonic frequency is converted to 20kHz, and the temperature of the center of the dough is reached. At -18°C, stop the ultrasound and take out th...

Embodiment 3

[0063] Take raw materials: 500g of flour, 10g of salt, 20g of yeast, and 300g of water are put into the blender evenly. Then put the dough into an 80cm*60cm*30cm ultrasonic-assisted freezing device, let it stand, and wait for the dough to proof. At the same time, connect the outlet and inlet of the refrigerant circulation to the refrigerator model HRS-140F, the temperature of the facility is -23°C, and turn on the equipment for precooling. Detect with 50kHz, 1000W ultrasonic waves. When Δα reaches 1.5, open the coolant circulation outlet and inlet with a flow rate of 6L / min. When the temperature of the center of the dough reaches -2°C, turn on the 80kHz, 1000W ultrasonic wave, with 10s as a working cycle, the ultrasonic wave works for 4s and stops for 6s. When the temperature in the center of the dough reaches -5°C, switch the ultrasonic frequency to 40kHz. When the temperature in the center of the dough reaches -18°C, stop the ultrasonic wave and take out the dough. Put it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com