Air suction valve for ultra-efficient double-reed refrigerator compressor

A technology for refrigerator compressors and suction valves, which is applied to mechanical equipment, machines/engines, and liquid variable capacity machinery, etc. It can solve the problems of difficult production and processing, poor fatigue resistance, and high production costs, and reduce the cost of raw materials , Improved fatigue resistance, improved cooling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

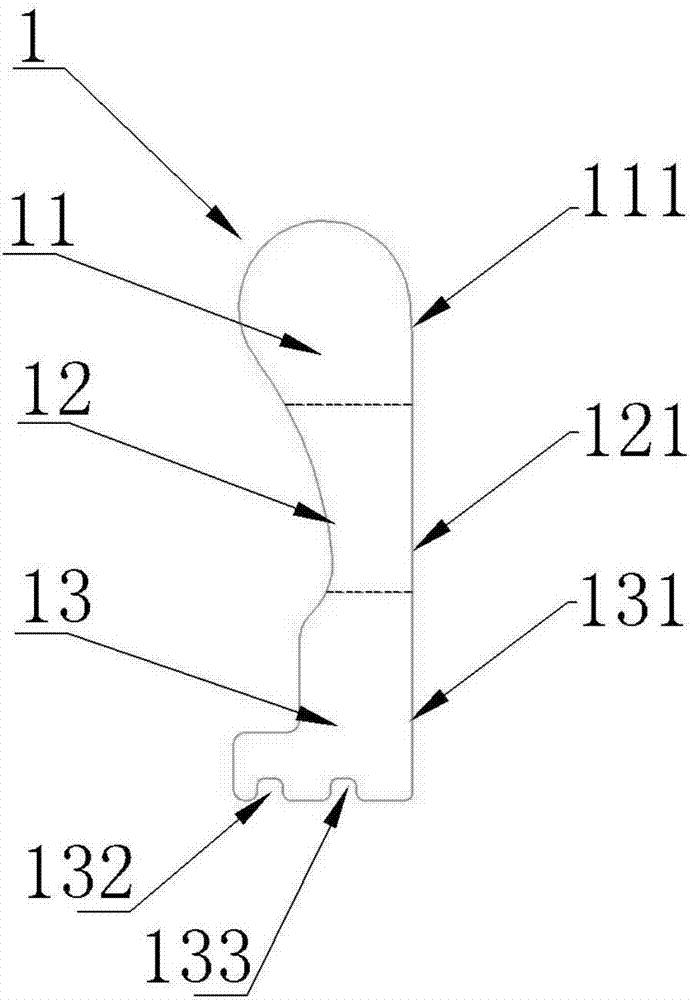

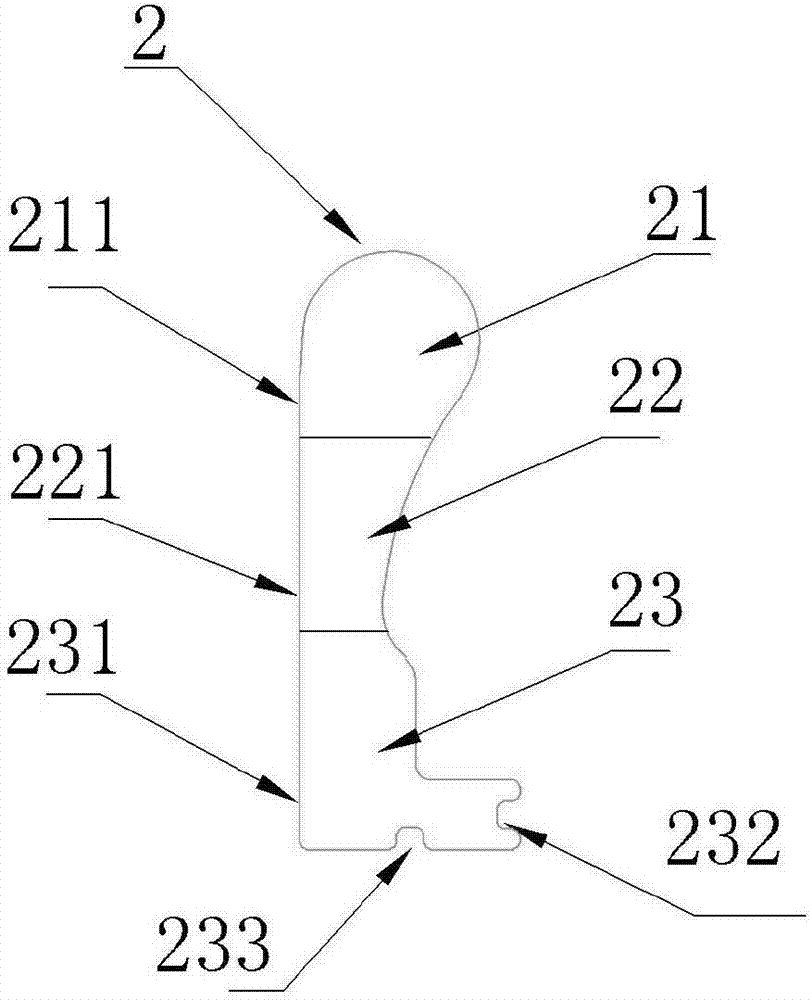

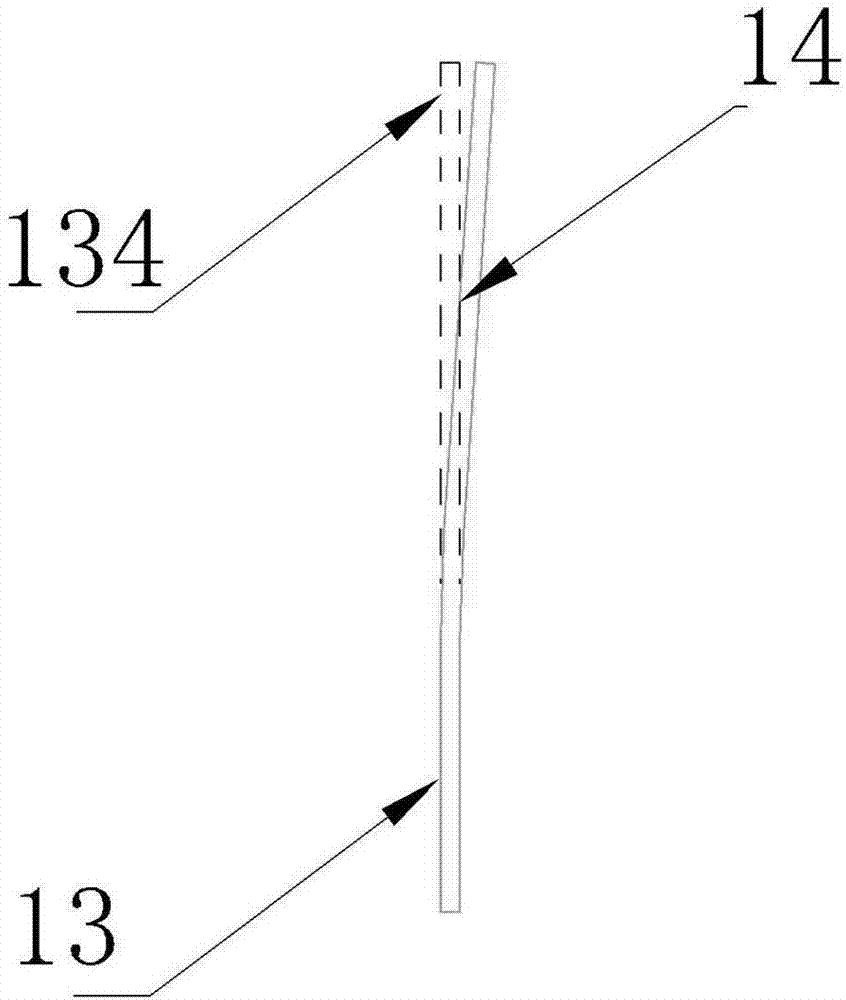

Embodiment 1

[0021] Embodiment 1 discloses a kind of ultra-efficient double reed refrigerator compressor suction valve plate, as Figure 6 As shown, it includes a left tongue reed 1, a right tongue reed 2 and a valve body 3 for installing the left tongue reed 1 and the right tongue reed 2, and the left tongue reed 1 and the right tongue reed 2 are installed and used in combination ,Such as figure 1 , figure 2 Shown, left tongue reed 1 comprises left reed tongue 11, left cantilever 12 and left fixed end 13, left cantilever 12 is positioned at the middle of left reed tongue 11 and left fixed end 13, the top of left cantilever 12 and left reed The bottom end of tongue 11 is fixedly connected, and the bottom end of left cantilever 12 is fixedly connected with the top of left fixed end 13; The inner edge 131 of the fixed end and the inner edge 111 of the left reed tongue are collinear to form the left line, and the left tongue reed 1 is in a q shape; the right tongue reed 2 includes the righ...

Embodiment 2

[0023] Embodiment 2 discloses an ultra-efficient dual-reed refrigerator compressor suction valve, including a left reed 1, a right reed 2, and a valve body for installing the left reed 1 and the right reed 2 3. The left tongue reed 1 and the right tongue reed 2 are installed and used in combination. The left tongue reed 1 includes a left reed tongue 11, a left cantilever 12 and a left fixed end 13. The left cantilever 12 is located between the left reed tongue 11 and the left In the middle of the fixed end 13, the top of the left cantilever 12 is fixedly connected with the bottom end of the left reed tongue 11, and the bottom end of the left cantilever 12 is fixedly connected with the top of the left fixed end 13; the left reed tongue 11, the left cantilever 12 and the left The fixed end 13 is integrally formed, and the inner edge 111 of the left cantilever, the inner edge 131 of the left fixed end and the inner edge 111 of the left reed tongue are collinear to form the left li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com