Telescopic valve handle

A valve handle and handle technology, applied in valve details, valve device, valve operation/release device, etc., can solve the problems of slow switching speed, small opening and closing torque of gate valve, and laborious switching, so as to speed up the switching speed and prevent The effect of level loosening and fast switching speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings.

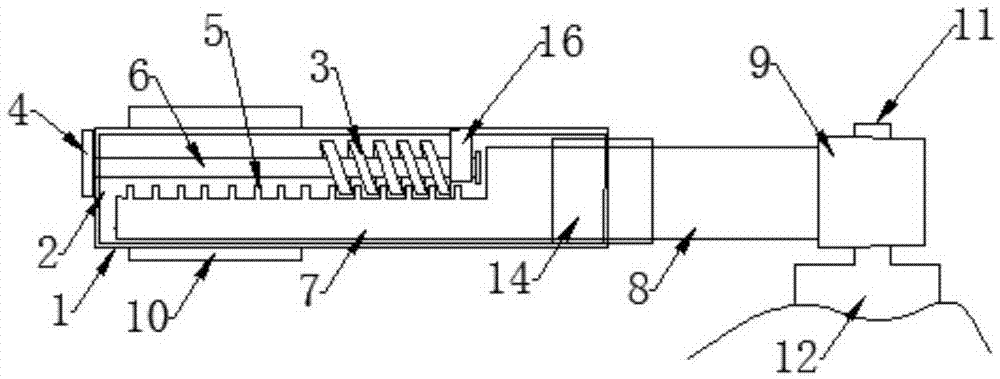

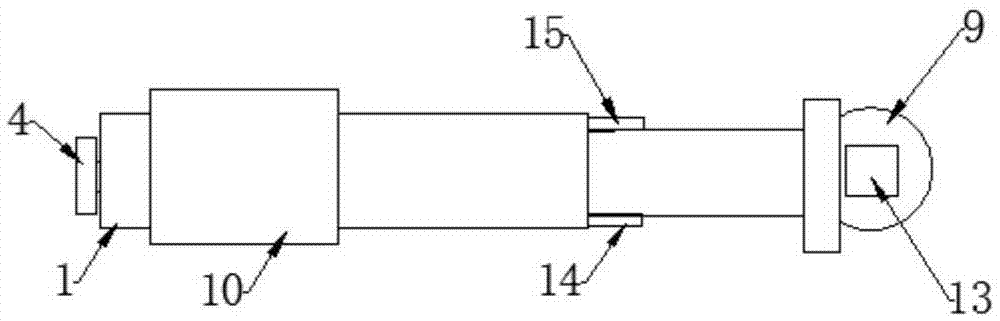

[0022] Such as figure 1 , figure 2 As shown, a telescopic valve handle of the present invention includes a fixed handle 1, a sliding cavity 2, a screw thread 3, a rotary knob 4, saw teeth 5, a screw shaft 6, a telescopic plate 7, a telescopic handle 8, a valve stem rotating plate 9, Grip cover 10, stem hole 13, front baffle 14, rear baffle 15, fixed block 16;

[0023] The fixed handle 1 is provided with a sliding chamber 2, and the sliding chamber 2 is provided with an axially rotatable screw shaft 6. The left end of the screw shaft 6 passes through the left side of the fixed handle 1 and is connected with the rotary knob 4. The fixed block 16 fixed on the top of the sliding cavity 2, the screw shaft 6 is provided with a screw thread 3;

[0024] A telescopic plate 7 is arranged below the screw shaft 6, and the upper surface of the telescopic plate 7 is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com