Anti-chopping shield with W-shaped shield body

A shield and anti-cutting technology, applied in the direction of defensive objects, can solve the problems of throwing liquid splash, lack of ability, damage, etc., and achieve the effect of avoiding splash, ensuring safety and good protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

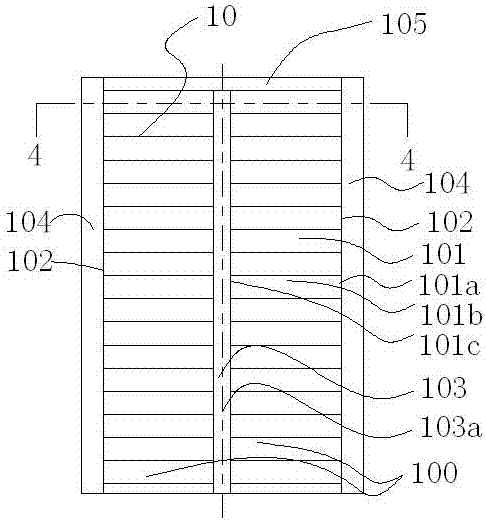

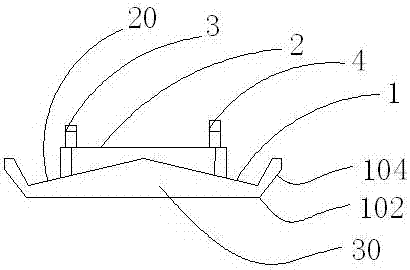

[0036] Embodiment 1: as Figure 1-4 As shown, a W-shaped shield is an anti-cut shield, which includes a shield body 1, a handle 4, a pad 2 and an elbow locking fixture 3, and the shield body 1 includes a shield body front 10 and a shield body back 20, the pad 2 is connected to the back 20 of the shield body, the handle 4 and the elbow locking fixture 3 pass through the pad 2 and connected to the shield body 1, wherein the shield body front 10 Including shield ridge 102, shield front 100, shield side 104 and shield bottom 103, the shield ridge 102 extends laterally to the shield bottom 103 to form the shield front 100, and the height of shield ridge 102 gradually decreases when it extends laterally, the definition of height here It is the distance from the front of the shield 100 to pad 2. The shield ridge 102 extends along the direction of the shield back 20 to form a shield side 104 , and the shield side 104 may also extend obliquely outward or inward along the direction of ...

Embodiment 2

[0046] Such as figure 1 and Figure 6 As shown, this embodiment provides another preferred technical solution for the structure of the second guide groove 106 on the basis of Embodiment 1, and what has been described in Embodiment 1 will not be repeated in this embodiment. Wherein, the shield bottom 103 further includes a second guide groove 106, and the second guide groove 106 is vertically arranged along the shield bottom axis 103a. The second guide groove 106 includes a groove opening 106a and a groove bottom 106b, the size of the groove opening 106a is smaller than the size of the groove bottom 106b, and the second guide groove 106 can be a convex groove or a dovetail groove or a pocket groove, or can be is a polygon slot. Compared with the situation in which the size of the groove opening 106a of the second guide groove described in the foregoing embodiment 1 is greater than or equal to the size of the groove bottom 106b, this technical solution is mainly for catching a...

Embodiment 3

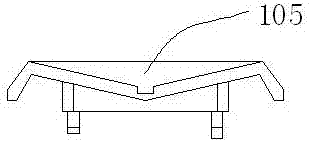

[0048] Such as Figure 7-8 As shown, this embodiment provides another preferred technical solution for the shield ridge 102 on the basis of the first embodiment. The content already described in Embodiment 1 will not be repeated in this embodiment. Wherein, the shield ridge 102 and the protective plate 105 surface are provided with anti-cutting strips 107, and the shield body 1 also includes a shield head 30, and the surface of the shield head 30 is also provided with anti-cutting strips 107, and the anti-cutting strips 107 can pass through The prior art methods such as bonding or screw connection are connected with the corresponding parts, and the anti-cut strip 107 is made of flexible or semi-rigid material, such as high-strength rubber material, which can effectively resist cutting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com