LED packaging module detection method and detection apparatus

A technology of LED packaging and detection methods, which is applied in the direction of diode testing and single semiconductor device testing, etc., can solve the problems of undetectable reverse current and false detection, and achieve the effect of improving the picking rate and the detection process is simple and reliable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below in conjunction with specific embodiments shown in the accompanying drawings. However, these embodiments do not limit the present invention, and any structural, method, or functional changes made by those skilled in the art according to these embodiments are included in the protection scope of the present invention.

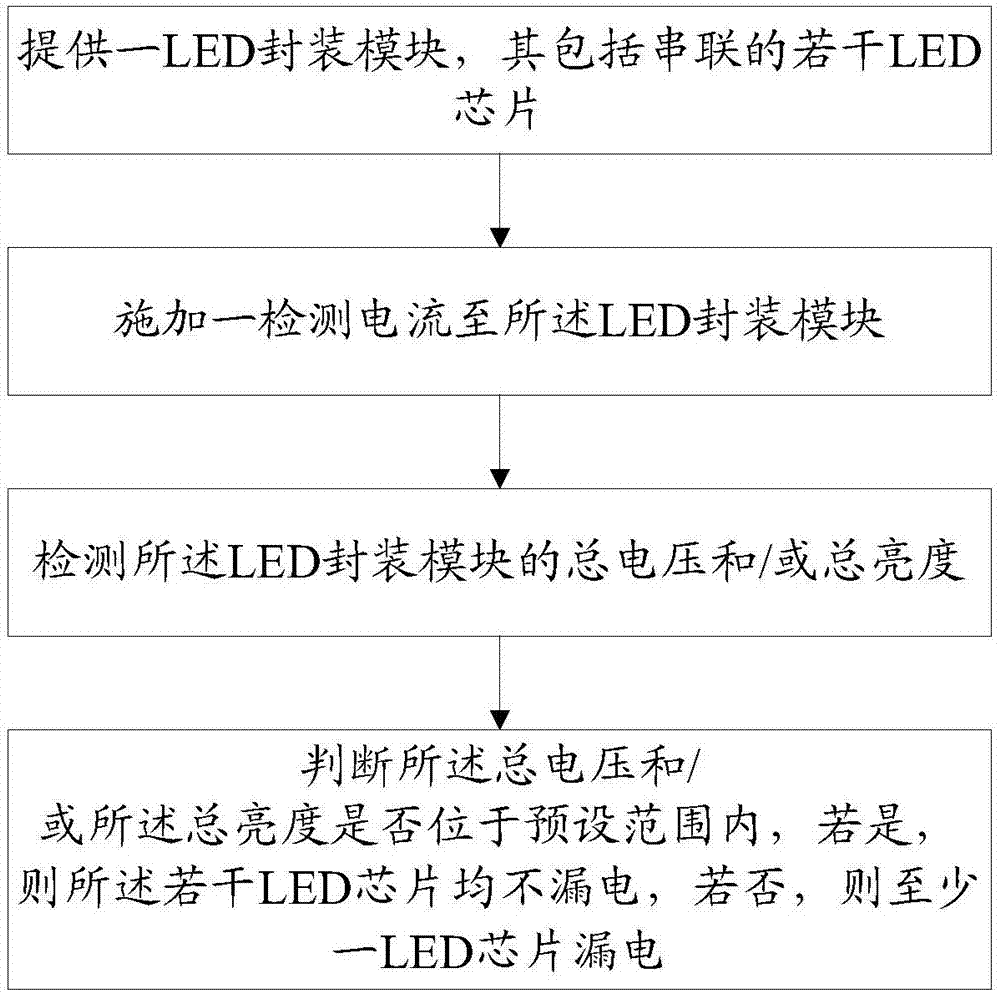

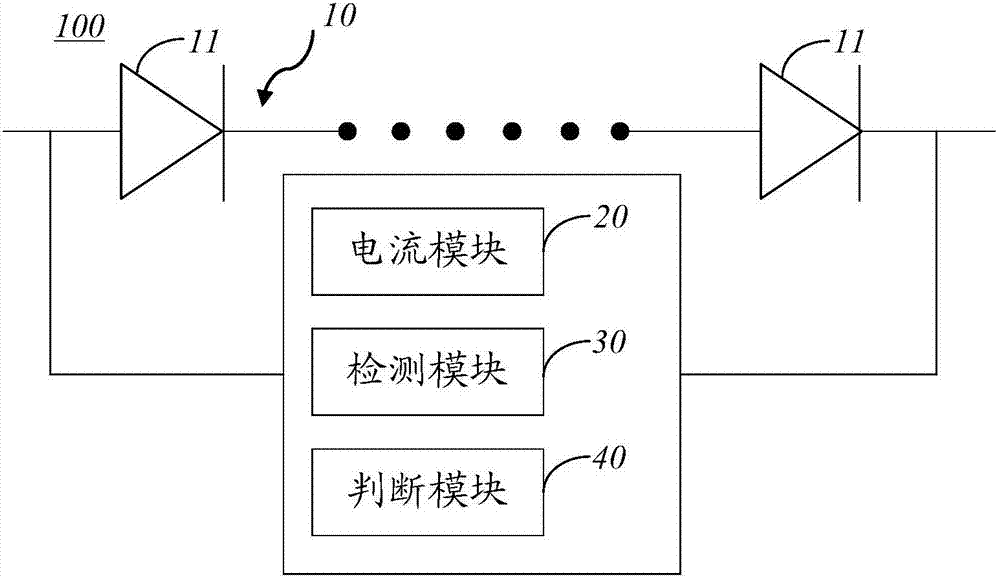

[0037] ginseng figure 1 , the LED packaging module detection method of one embodiment of the present invention comprises steps:

[0038] Provide an LED packaging module, which includes a number of LED chips connected in series;

[0039] applying a detection current to the LED packaging module;

[0040] Detecting the total voltage and / or total brightness of the LED packaging module;

[0041] Judging whether the total voltage and / or the total brightness is within a preset range, if yes, none of the plurality of LED chips leaks electricity, if not, at least one LED chip leaks electricity.

[0042] Her...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com