Mechanical touching type conveyor belt tearing detection method

A detection method and conveyor belt technology, applied in the direction of conveyor objects, conveyor control devices, transportation and packaging, etc., can solve the problems of poor underground transportation conditions, high price, unreliability, etc., and achieve simple, reliable and accurate detection in the detection process The effect of high rate and improved detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

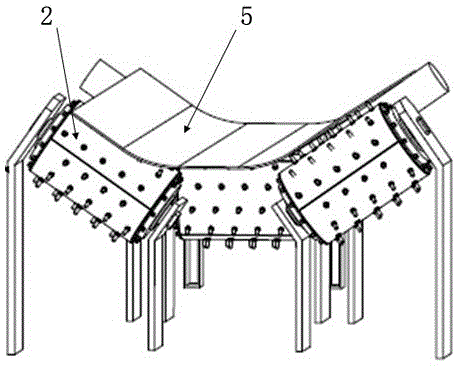

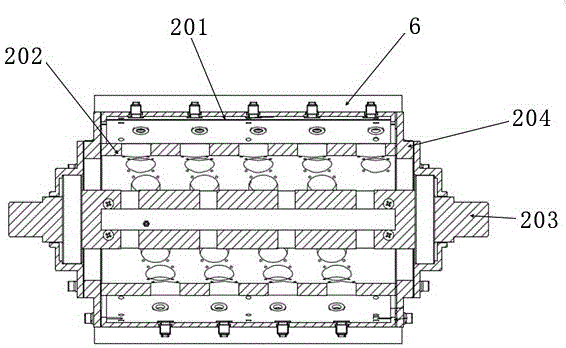

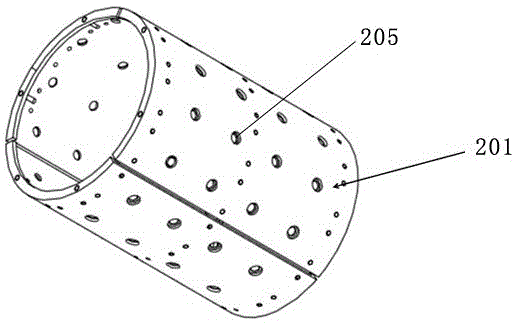

[0026] A mechanical touch conveyor belt tear detection method uses a probe 1 arranged on a rotating body 2 that rotates with a conveyor belt 5 to contact the surface of the conveyor belt to form a touch detection. When the conveyor belt 5 is normal, when the probe 1 contacts the conveyor belt with the rotation of the rotating body 2, the conveyor belt 5 presses the probe 1 to compress the elastic element 7, so that the elastic element produces an effect on the probe. needle elasticity. When encountering the torn area on the surface of the conveyor belt, the elastic force applied by the elastic element 7 connected to the probe 1 causes the probe to be inserted into the crack on the surface of the conveyor belt, and when the probe is inserted into the crack, the probe is connected to the probe The trigger mechanism 9 touches the trigger switch 8, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com