Optical unit with shake correction function and method of manufacturing the same

A shake correction, optical unit technology, applied in the direction of optical components, optical, electrical components, etc., can solve the problem of not being able to form a stop mechanism that limits the swing range of the movable body, and achieve the effects of preventing excessive swing, efficient manufacturing, and downsizing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

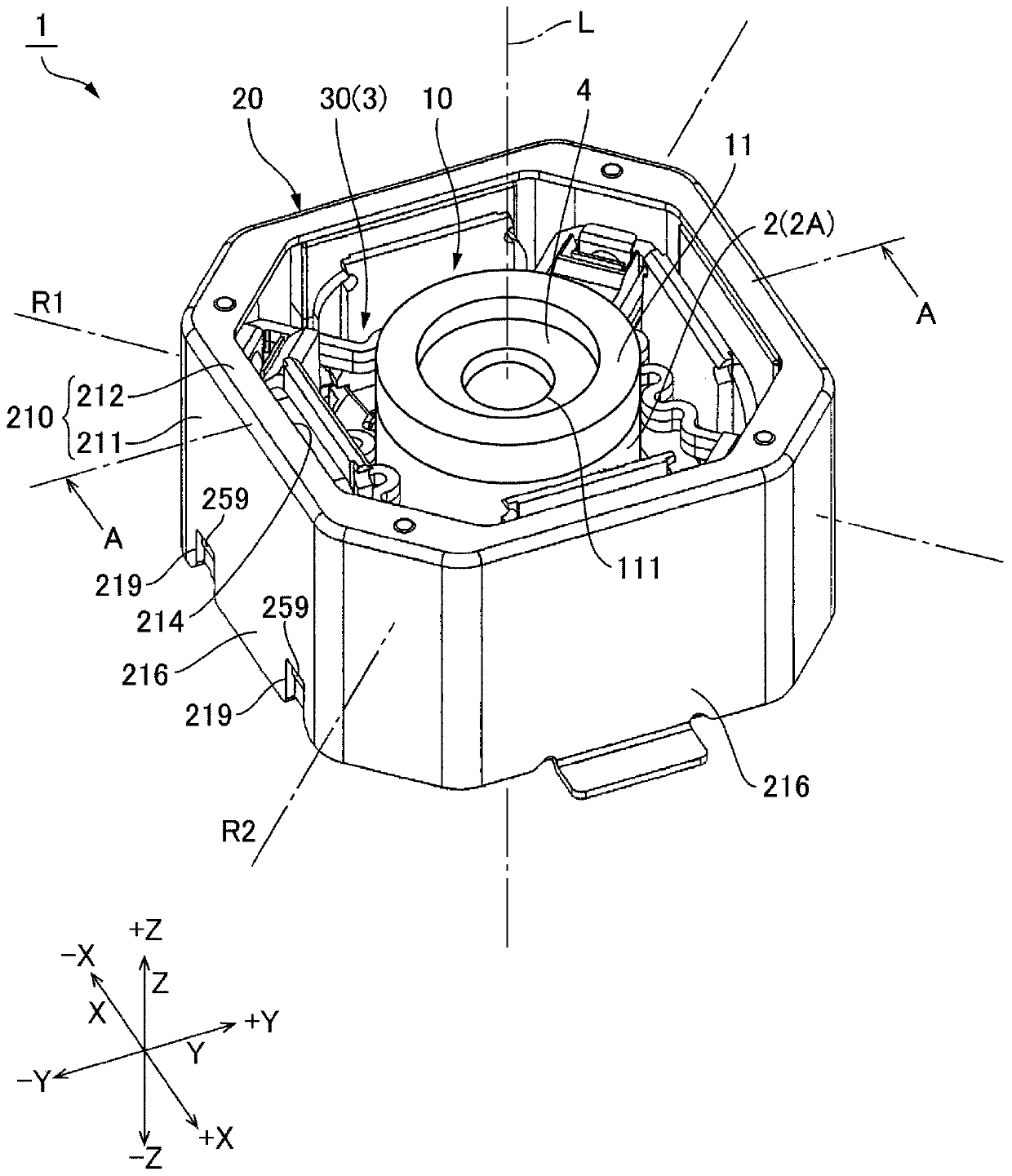

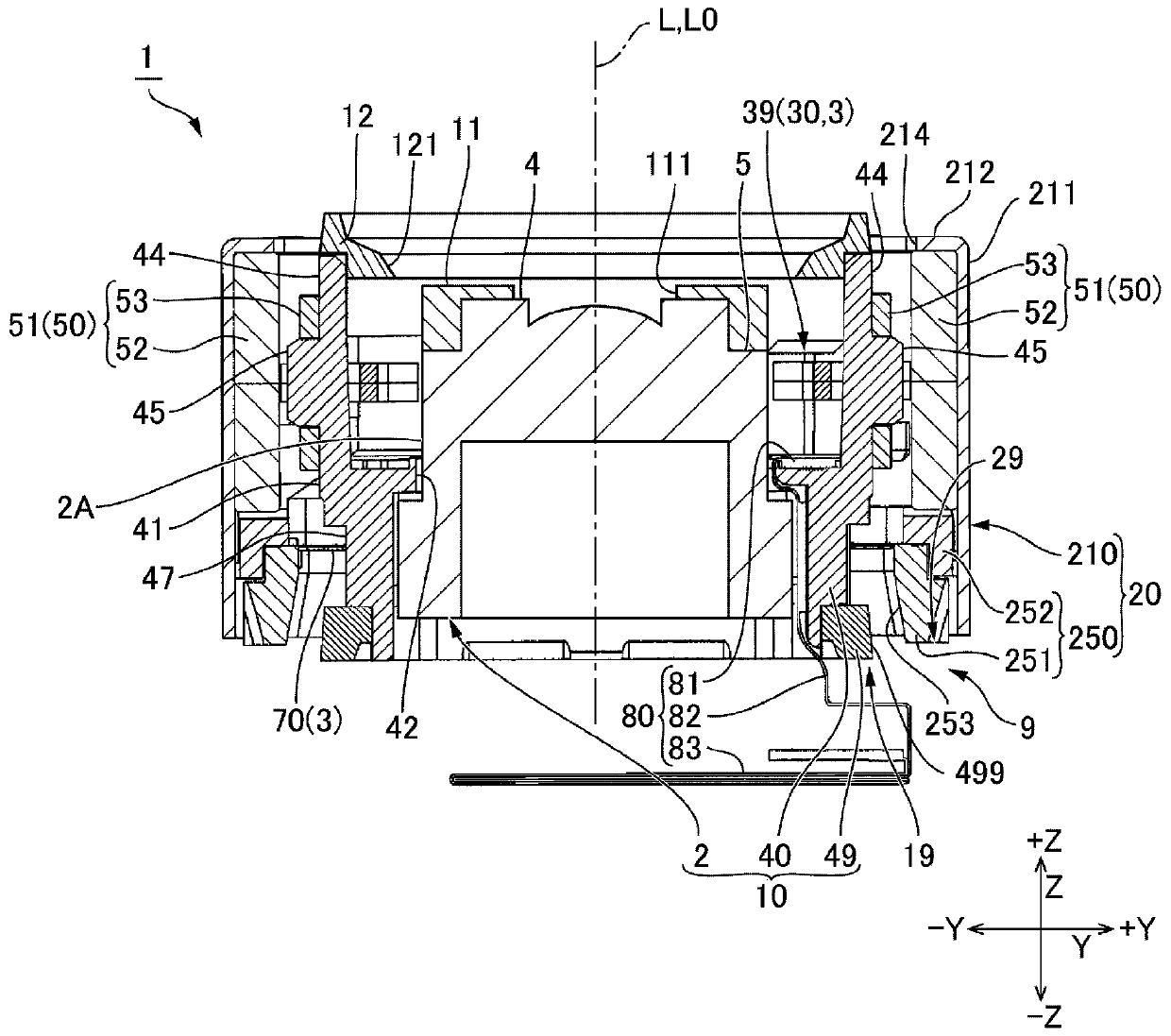

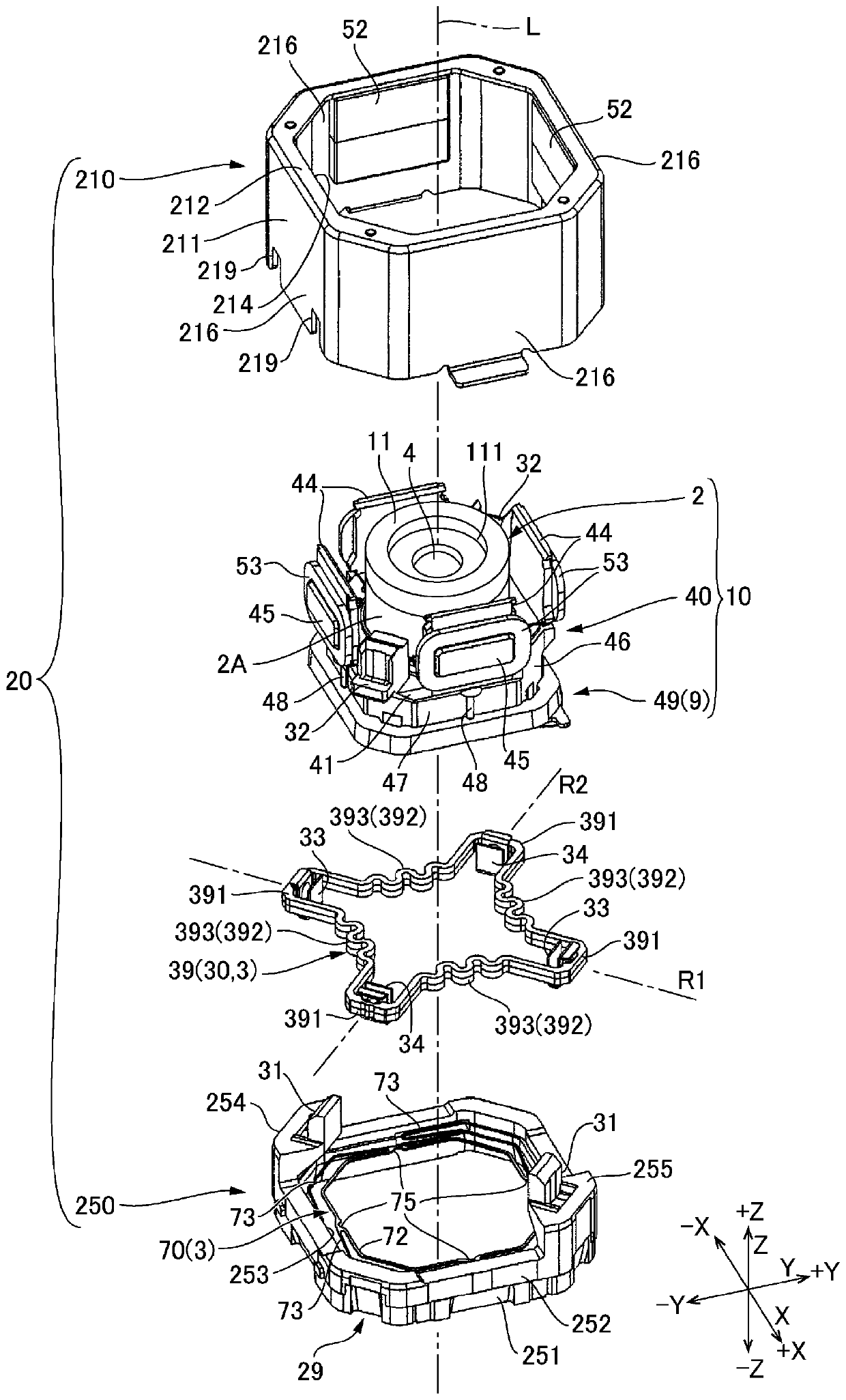

[0072] An optical unit 1 with a shake correction function to which the present invention is applied will be described with reference to the drawings. In the following description, the three axes of XYZ are mutually orthogonal directions, +X indicates one side of the X-axis direction, -X indicates the other side of the X-axis direction, and +Y indicates one side of the Y-axis direction , Use -Y to indicate the other side of the Y-axis direction, use +Z to indicate one side of the Z-axis direction, and use -Z to indicate the other side of the Z-axis direction. The Z-axis direction is the central axis L of the optical unit 1 with a shake correction function. The direction of the central axis L is the direction of the optical axis of the optical module 2 installed in the optical unit 1 with shake correction function. The −Z direction is a direction toward the image side of the optical axis direction, and the +Z direction is a direction toward the object side of the optical axis d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com