Electromechanical Servo Brake

A servo brake, electromechanical servo technology, applied in the direction of brakes, brake transmission devices, hydraulic brake transmission devices, etc., can solve problems such as wear and loss of freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

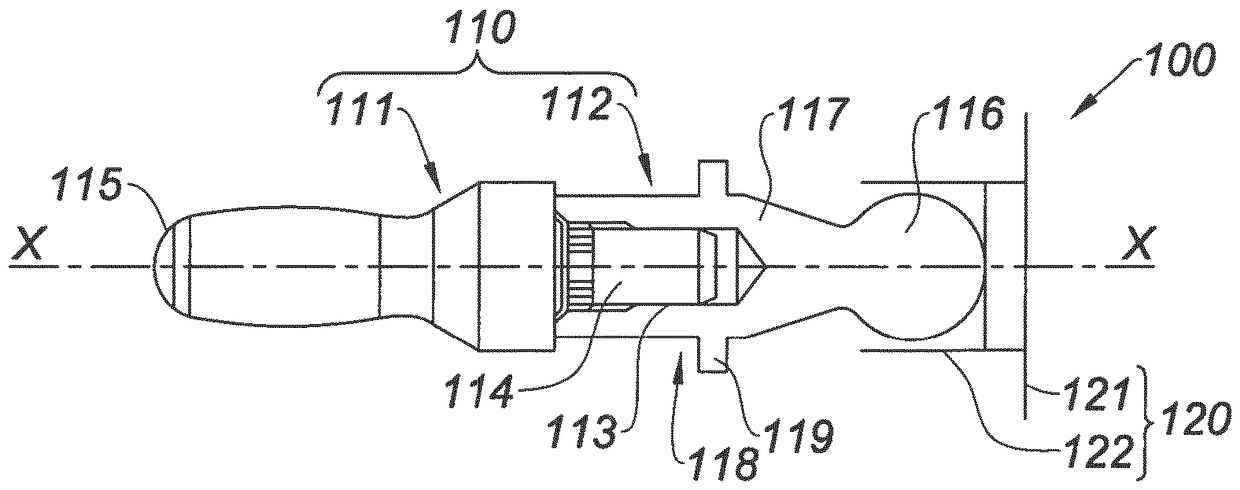

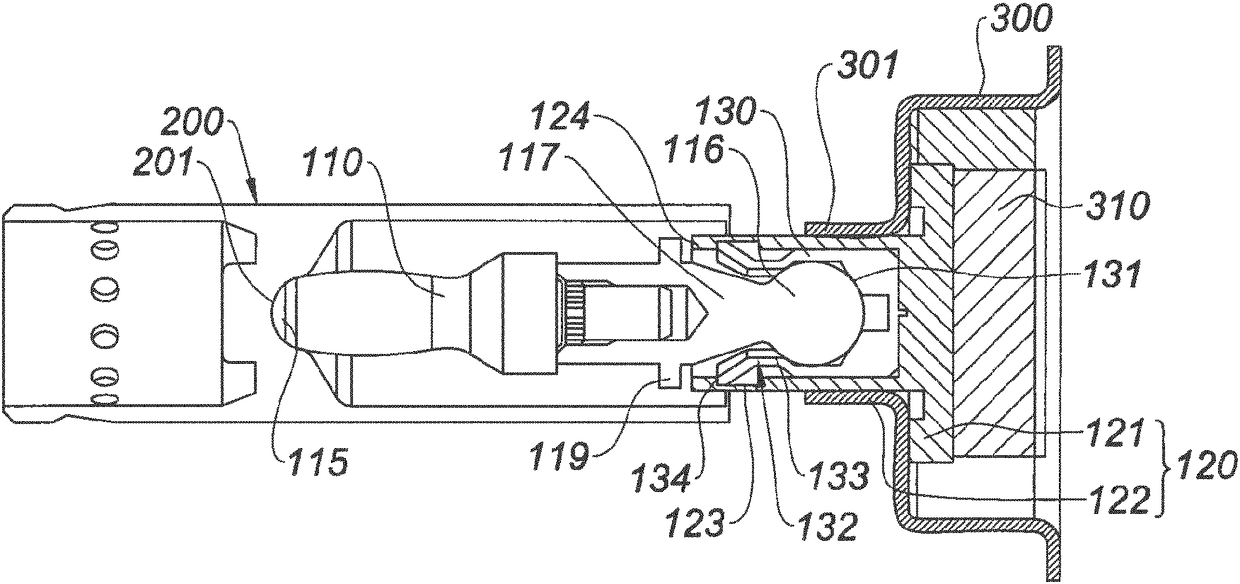

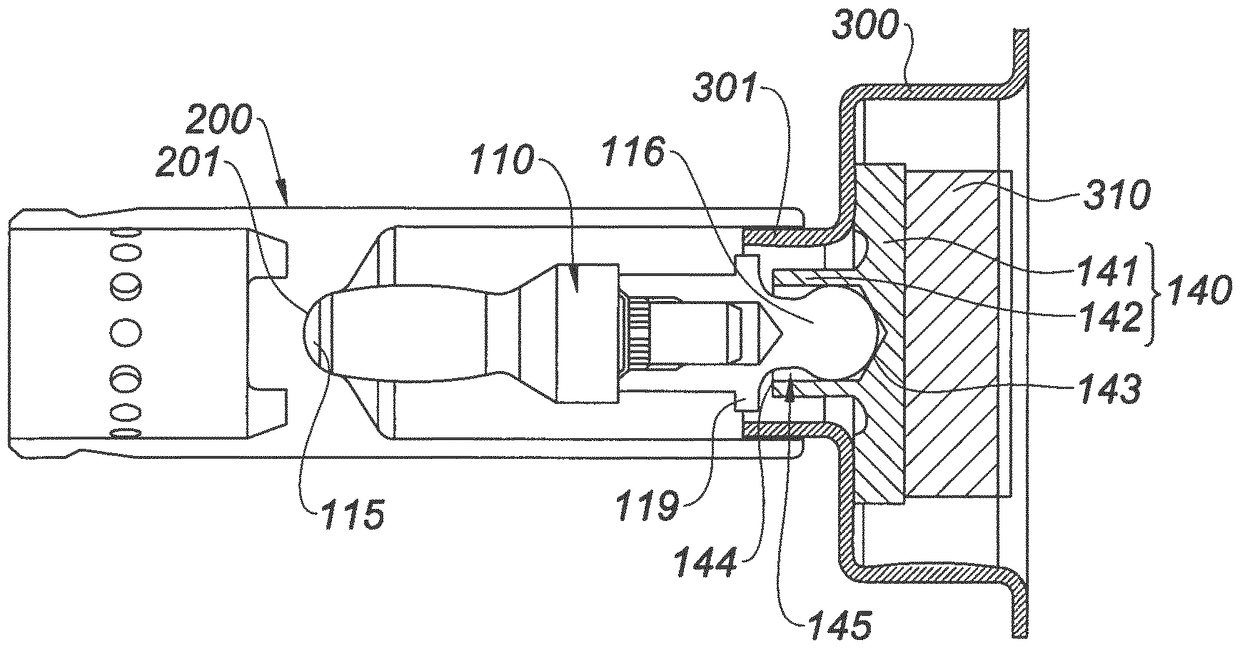

[0022] To simplify the description, by convention, such as figure 1 As shown, the front (AV) of the servo brake is on the side of the tandem master cylinder and the rear (AR) is on the side of the lever actuated by the brake pedal.

[0023] figure 2 A thrust unit 100 of a servo brake according to the invention is shown very schematically for transmitting the thrust of the auxiliary piston to the main piston. The thrust unit 100 comprises a push rod 110 and a bearing 120 which receives one end of the push rod and bears against the auxiliary piston, while the other end of the push rod bears in the coupelle of the main piston. The push rod 110 is made in two parts, where the front part 111 and the rear part 112 are assembled together by a tight fit. A section of the front part 111 is not shown, but a section of the rear part 112 is shown.

[0024] The rear part 112 has a cylindrical groove 113 for positively fitting the main shaft 114 of the front part 111 and constitutes a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com