Flameproof, aliphatic polyketone materials, moulded articles produced therefrom and also method for the production thereof

An aliphatic polyketone, polyketone technology, applied in the field of phosphinate, halogen-free fireproof molding material, can solve the problem of non-prevention and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

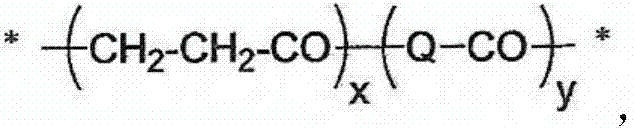

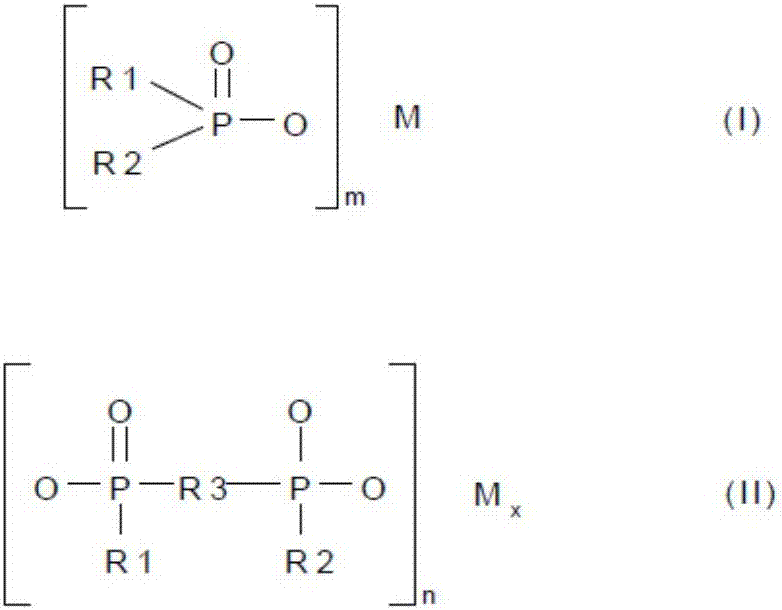

Method used

Image

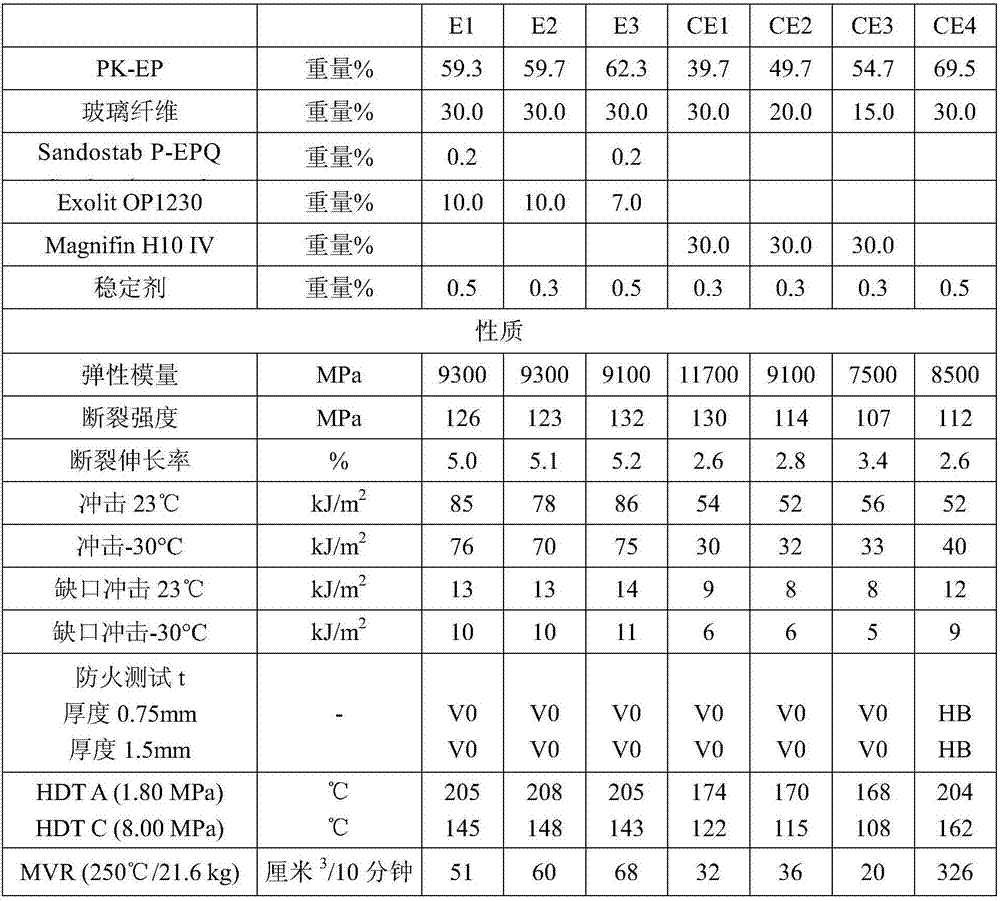

Examples

Embodiment Construction

[0091] Preferred embodiments of the invention are described below with reference to embodiments given by way of illustration, which are for illustration only and are not to be construed as limiting.

[0092] Preparation of polyketone molding compound:

[0093] The raw materials of components (A), (C) and (D) were premixed and fed by weight into a twin-screw extruder of type ZSK25 (Werner and Pfleiderer). Component (B) was metered into the melt via a sub-feeder by 4 shell units before discharge. Processing was performed at a cylinder temperature of 200°C to 270°C, with a rotary screw speed of 200 rpm and a throughput of 10 kg / hour. The compound is discharged through a nozzle and pelletized after cooling the wire. Drying was then carried out in vacuum at 100° C. for 24 hours.

[0094] Preparation of molded articles:

[0095] The production of the molded articles was carried out on an injection molding machine Arburg Allrounder 420C-1000-250 in the rising cylinder tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com