Method for improving quantum dot luminescence through core-shell structural nanoparticles

A quantum dot luminescence and nanoparticle technology, which is applied in nano optics, nanotechnology for materials and surface science, nanotechnology, etc., can solve the problem that quantum dot luminescence behavior is not obtained, and achieve simple preparation methods and raw materials, and improve Optical behavior and the effect of widening the range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Preparation of a core-shell nanoparticle:

[0034] figure 1 A schematic diagram of the experimental flow for core-shell nanoparticles is given.

[0035] Take thin-layer silica-coated silver core-shell nanoparticles as an example. Its specific preparation method is:

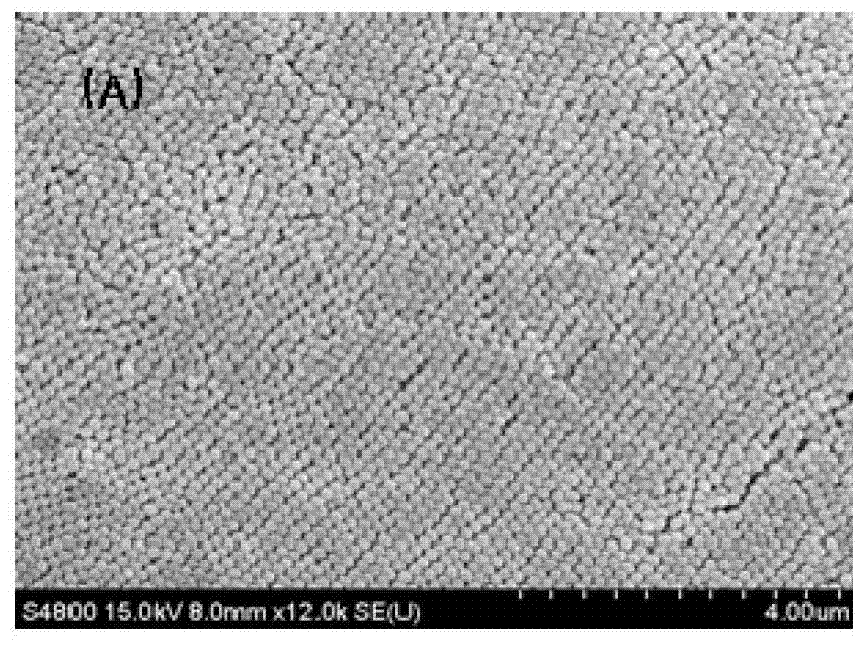

[0036] Take 200 mL of 0.01% chloroauric acid aqueous solution, heat it to boiling under stirring conditions, then add 1.6 mL of 1% sodium citrate aqueous solution, and keep boiling slightly for 50 min, the solution gradually turns brownish red, Allow it to react completely and cool down to room temperature naturally to obtain a gold nanoparticle sol with a diameter of about 45±10 nm. Take 10 mL of gold nanoparticle sol as a seed, dilute it ten times, and gradually add 4 mL of 20 mM silver nitrate into the seed solution containing a certain amount of sodium citrate and ascorbic acid to obtain silver-coated gold with a particle size of 150±10 nm. Nanoparticles. Take the above silver-coated gold nanoparti...

Embodiment 2

[0039] Detection of enhanced fluorescence of core-shell nanoparticles on glass flake-assembled quantum dots.

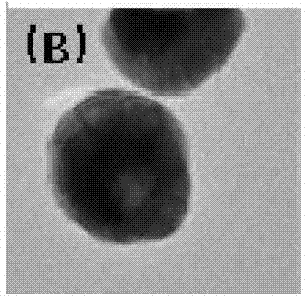

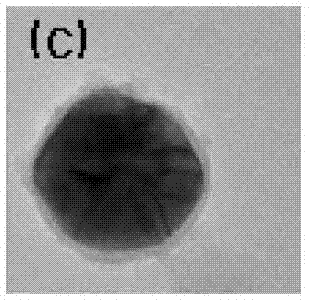

[0040] Synthesis of oil-phase CdSe nanoparticles and a novel inorganic perovskite CsPbBr by high-temperature hot-injection method 3 quantum dots, Figure 3A Fluorescence photos and transmission electron microscope images of oil-phase CdSe quantum dots, Figure 3B Inorganic CsPbBr 3 Fluorescence photographs and transmission electron microscope images of quantum dots. The particle size of CdSe quantum dots in the figure is -3.7 nm, CsPbBr 3 Particle Size - 8 nm.

[0041] Quantum dots were assembled by chemical adsorption method / LB film / spin-coating / dip-coating. The specific implementation is as follows. The surface of the glass substrate is aminated with aminosilane, and the aminated substrate is soaked in a solution containing quantum dots. Due to the ligand exchange between the amino group and the quantum dots, the quantum dots are thus adsorbed on the surface o...

Embodiment 3

[0044] Detection of enhanced fluorescence of gold flake-assembled quantum dots by core-shell nanoparticles.

[0045] The gold film is constructed by thermally evaporating a gold layer / magnetron sputtering gold layer / and single crystal Au(111) with a thickness of about 200 nm on the surface of the silicon wafer. The silicon wafer is cleaned by Piranhas Solution (H 2 SO 4 :H 2 o 2 -1:2), toluene / isopropanol (1:1), acetone / isopropanol (1:1), ethanol, ultrapure water for ultrasonic cleaning. In order to avoid self-quenching caused by energy transfer in direct contact between the quantum dots and the gold film, we deposited a nanometer-thick aluminum oxide dielectric layer on the surface of the gold film using atomic layer deposition technology, which can effectively avoid the quenching phenomenon caused by direct contact, and at the same time The thick aluminum oxide layer will not interfere with the coupling phenomenon of the system.

[0046] Chemical adsorption method: immer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap