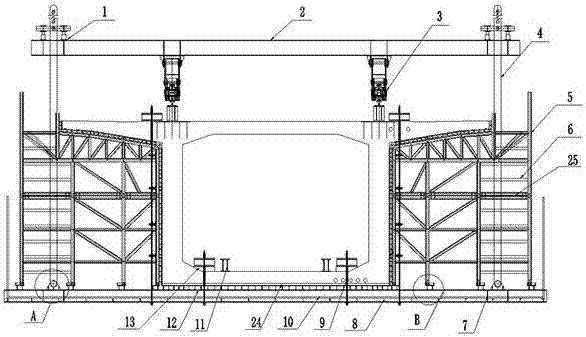

Multifunctional railway line-crossing swing bridge closure construction formwork and construction method thereof

A railway line, multi-functional technology, applied in the field of formwork application, can solve the problems of steel shell becoming a hidden danger in the later stage, existing line damage, and difficulty in hanging baskets retreating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

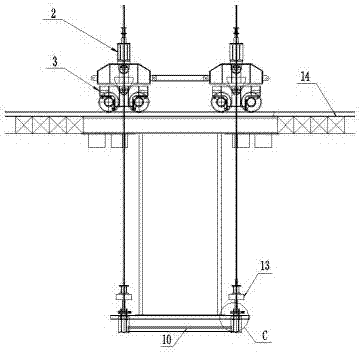

[0031] Used in lifting rails, the steps are as follows:

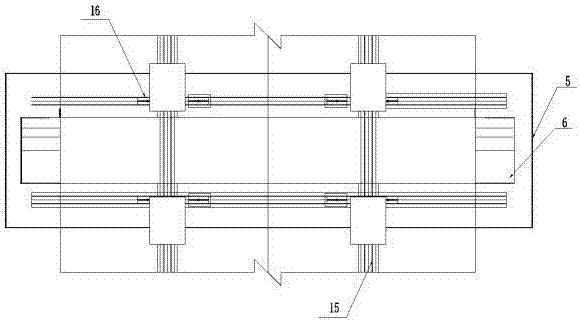

[0032] Step A. According to the functional requirements, special design and processing are required. The bottom of the lateral steel formwork 25 that can be moved laterally is welded to the reinforcing column 17, and the original column of the lateral steel formwork 25 is jointly stressed, and the rolling bearing 20 is connected to the original column of the formwork through the pin. Connected with the reinforcement column 17;

[0033] Step B, before the construction of the mid-span closure, install the lateral steel formwork 25 that can move laterally on the traveling equipment, and use the limit pins 18 to pin and fix the lateral steel formwork 25. A limit stop 22 of hard wood is set on the limit bottom plate 23 at the bottom, and a walking pair tie rod 24 is installed before walking;

[0034] Step C, utilize the movable hoisting equipment to transport the hanger section hanger and the lateral steel formwork 25 to th...

Embodiment 2

[0040] Applied in lifting cement board, the steps are as follows:

[0041] Step A. According to the functional requirements, special design and processing are required. The bottom of the lateral steel formwork 25 that can be moved laterally is welded to the reinforcing column 17, and the original column of the lateral steel formwork 25 is jointly stressed, and the rolling bearing 20 is connected to the original column of the formwork through the pin. Connected with the reinforcement column 17;

[0042]Step B, before the construction of the mid-span closure, install the lateral steel formwork 25 that can move laterally on the traveling equipment, and use the limit pins 18 to pin and fix the lateral steel formwork 25. A limit stop 22 of hard wood is set on the limit bottom plate 23 at the bottom, and a walking pair tie rod 24 is installed before walking;

[0043] Step C, utilize the movable hoisting equipment to transport the hanger section hanger and the lateral steel formwork...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com