Frame structure with self resetting function

A frame structure, self-resetting technology, applied in the direction of truss-type structure, elongated structural members for load-bearing, structural elements, etc., can solve the problems of complex seismic action, large residual deformation of components, damage to structural components, etc. Achieve good economy and convenience, good ductility and energy consumption, and meet the effect of ductility and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

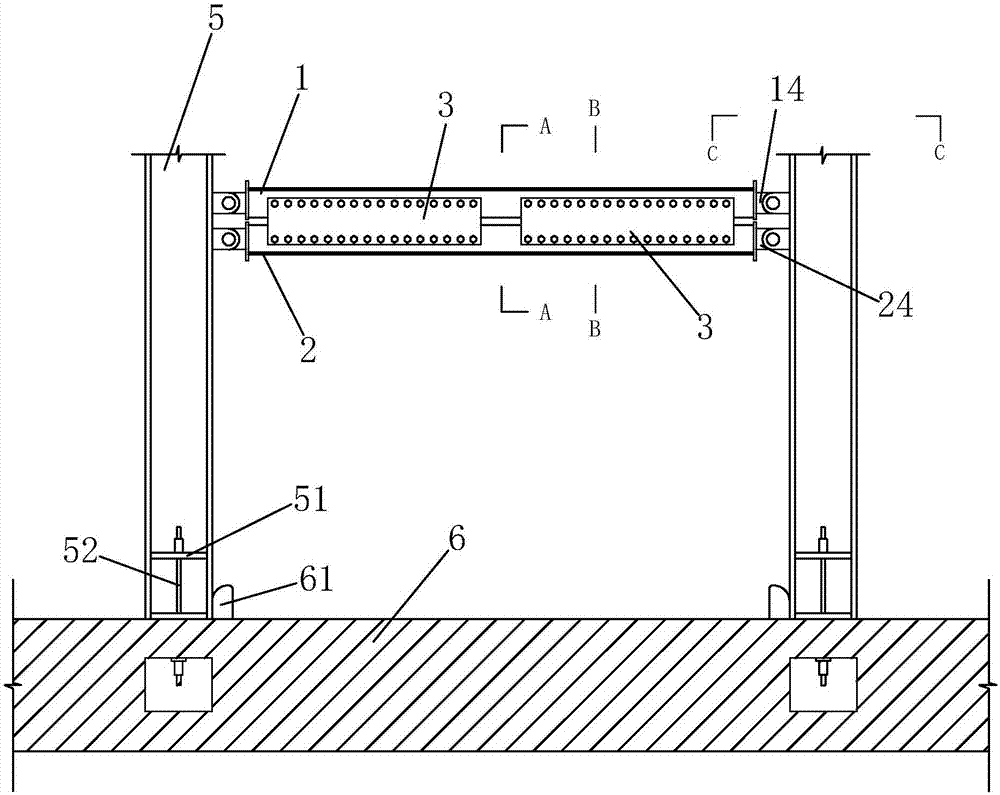

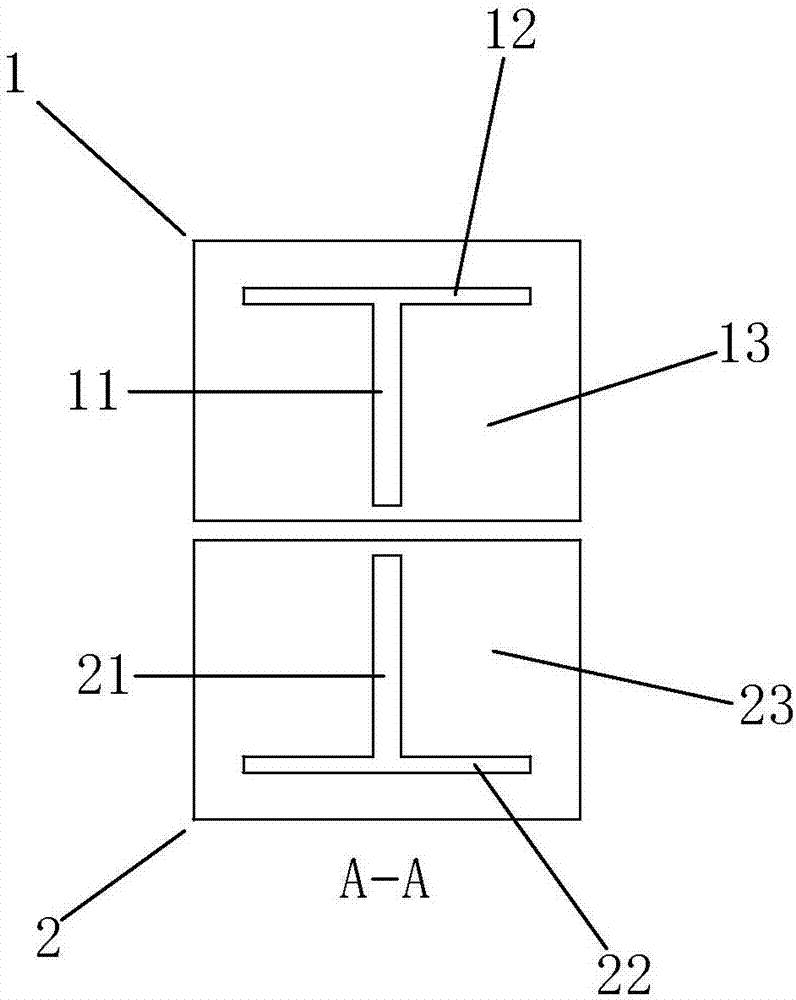

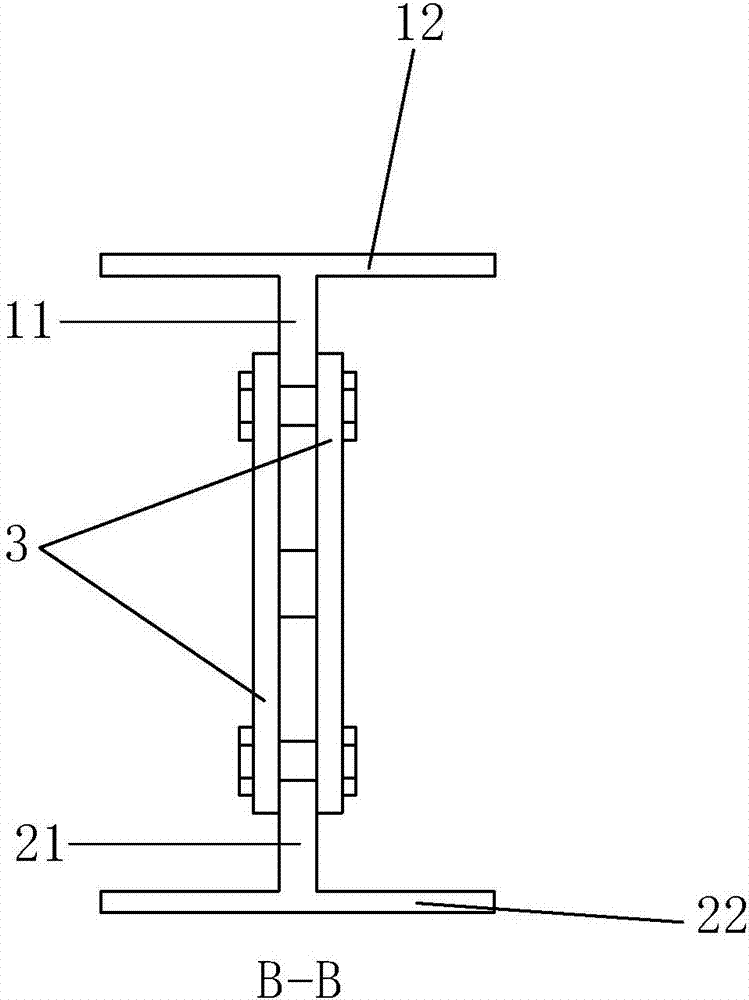

[0033] Such as figure 1 As shown, a frame structure with self-resetting function includes a T-shaped upper bar 1, a T-shaped lower bar 2, two pairs of hard connecting steel plates 3 and two I-shaped columns 5.

[0034] Such as figure 1 and figure 2 As shown, the T-shaped upper bar 1 includes an upper web 11 and an upper top plate 12 fixedly connected to each other, and an upper end plate 13 is respectively fixed at both ends, and an upper ear plate 14 protrudes from the upper end plate 13, as Figure 5 As shown, in addition, the upper web 11 of the T-shaped upper rod 1 is provided with two elongated through holes 15 parallel to the length direction of the T-shaped upper rod 1 and arranged in sequence along the length direction of the T-shaped upper rod 1;

[0035] Such as figure 1 and figure 2 As shown, the T-shaped lower rod 2 includes a lower web 21 and a lower bottom plate 22 fixedly connected to each other, and the lower end plates 23 are respectively fixed at both e...

Embodiment 2

[0041] Such as Figure 6 As shown, a frame structure with self-resetting function is arranged between two I-shaped columns 5, including a T-shaped upper rod 1, a T-shaped lower rod 2, two pairs of mild steel plates 4 and two I-shaped columns 5 .

[0042] The T-shaped upper rod 1 includes an upper web 11 and an upper top plate 12 fixedly connected to each other, and an upper end plate 13 is respectively fixed at both ends, and an upper ear plate 14 protrudes from the upper end plate 13;

[0043] The T-shaped lower rod 2 includes a lower web 21 and a lower bottom plate 22 fixedly connected to each other, and a lower end plate 23 is respectively fixed at both ends, and a lower ear plate 24 protrudes from the lower end plate 23;

[0044] Such as Figure 6 and Figure 8As shown, two I-shaped columns 5 are vertically placed on the concrete foundation 6, and a stiffening rib 51 is fixed on both sides of the web of each I-shaped column 5, and each stiffening rib 51 is passed throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com