Marine steel-made fireproof door easy to open

A technology for fire doors and ships, which is applied in the direction of fire doors, door leaves, building fastening devices, etc. It can solve the problems of poor sound insulation performance, inconvenient use, and unstable locking, etc., and achieve good fire and heat insulation effects, stable locking, Turn on handy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

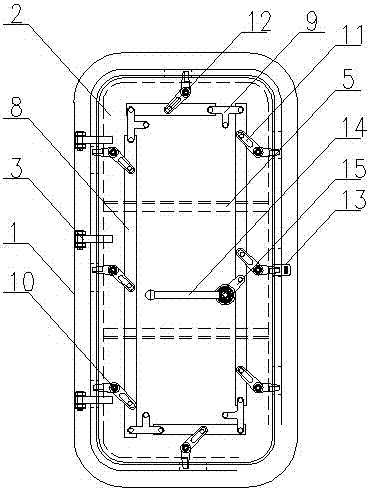

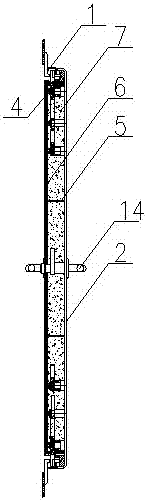

[0012] Below in conjunction with accompanying drawing, the specific embodiment of the present invention is described in further detail:

[0013] As shown in the figure, the marine easy-to-open steel fire door includes a door frame 1 and a door body 2. One side of the door body 2 is installed on the door frame 1 through a hinge 3, and a ring of sealing strip 4 is installed on the inner edge of the door body 2. The door When the body 2 is closed, the sealing strip 4 is attached to the door frame 1 . The door body includes a steel door panel and four side sealing panels, and the door panel and the sealing panel are welded or fixed by bolts. A plurality of parallel reinforcing ribs 5 are welded and installed between the front and rear door panels, and the two ends of the reinforcing ribs 5 are welded to the four side sealing plates. A calcium silicate board layer 6 is installed on the inner side of the front door panel, and ceramic wool 7 is filled between the calcium silicate bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com