Rapid cold stretch bending technology for thin-walled small-radius pipes

A small-radius, cold-drawn bending technology, applied in the field of pipe bending, can solve the problems of messy workplaces, unfavorable health of workers, poor air quality, etc., and achieve the effect of good pipe quality, simple structure and good support.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

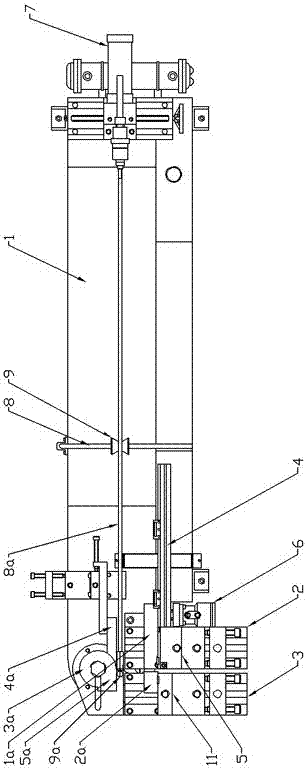

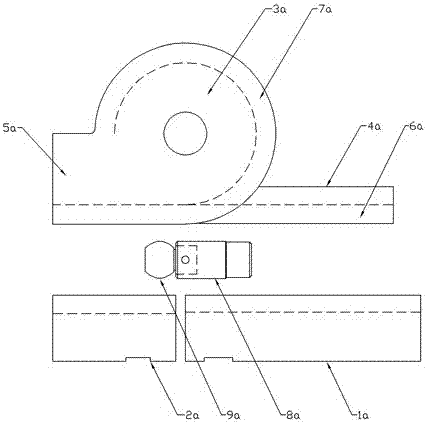

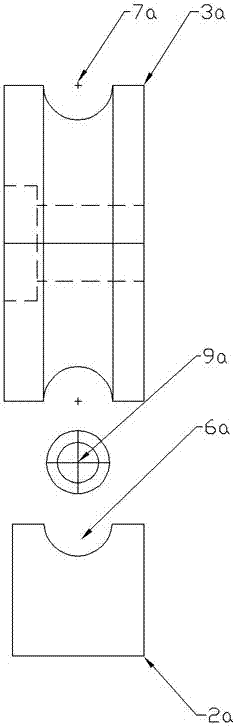

[0019] like Figure 1 to Figure 4 As shown, in this embodiment, the thin-walled small-radius pipe rapid cold-drawing bending technology uses a thin-walled small-radius pipe bender to perform rapid cold-drawn bending of thin-walled small-radius pipes, and the thin-walled small-radius pipe bend The pipe machine includes a body 1 and a fixed arm 2 arranged on the body 1, a rotating arm 3 and a pipe bending die, and the fixed arm 2 and the rotating arm 3 are all arranged on the body 1; Mold comprises guide mold 1a, clamping mold 2a, circular mandrel 3a and anti-wrinkle mold 4a, described circular mandrel 3a is provided with the straight die 5a that matches with described clamping mold 2a, and described anti-wrinkle mold 4a sticks Lean against one side of the circular core mold 3a, and the end of the anti-wrinkle mold 4a is provided with an arc suitable for the circular core mold 3a, and the guide mold 1a is located on the side of the clamp mold 2a Front and compatible with the an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com