A kind of preparation method of heap carving ceramic plate decorative painting

A technology for ceramic plates and decorative paintings, applied in special decorative structures, processes for producing decorative surface effects, decorative arts, etc., can solve the problems of insufficient three-dimensional 3D effect, blunt etched edges, and insufficient colors. Rich feel, easy to take care of, smooth and natural effect of picture bump transition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the drawings and the following embodiments. It should be understood that the drawings and the following embodiments are only used to illustrate the present invention rather than limit the present invention.

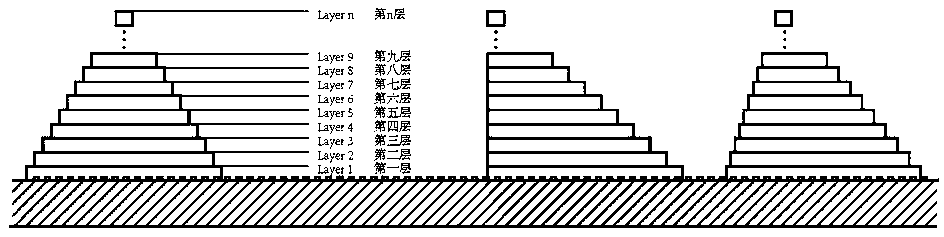

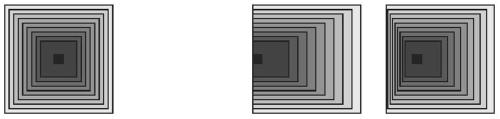

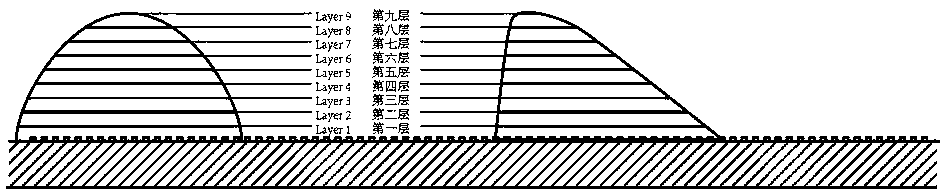

[0025] The present invention adopts the method of stacking glazes to make decorative paintings on ceramic plates: computer 3D digital stacking glaze technology, three-dimensional presentation. Strong three-dimensional sense, good permeability, high fidelity, with a unique decorative effect.

[0026] Step 1: Use a ceramic plate, which can be a large-scale ceramic plate, for example, the product specification can be 900mm×1800mm×(3.5-5.5)mm, or 1200×2400×(3.5-5.5)mm. Cut to the specified size according to the size of the pattern (the mosaic picture of the first mate is not cut). In addition, the ceramic plate is preferably an environment-friendly ceramic plate. In one example, environmental p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com