Surface defect detection method of robust based on machine vision

A technology of machine vision and defect detection, applied in the field of image processing, to achieve the effect of convenient application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

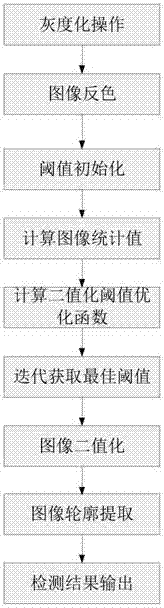

[0033] In this embodiment, the circular defect detection on the metal surface is taken as an example for illustration, and the process is as follows figure 1 As shown, the specific implementation of the detection steps:

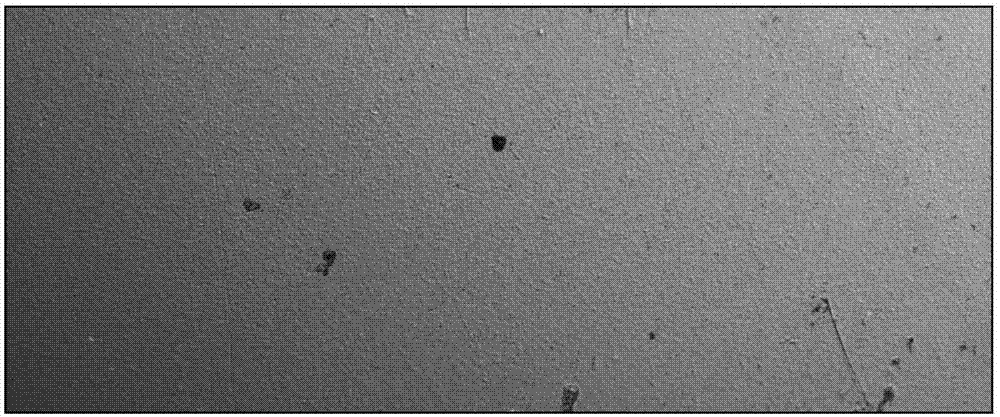

[0034] Step 1: Grayscale processing. The image of the surface to be detected is collected by the camera. If it is a color image, it is grayscaled first to obtain a grayscale image I. The grayscale image I is as follows: figure 2 shown.

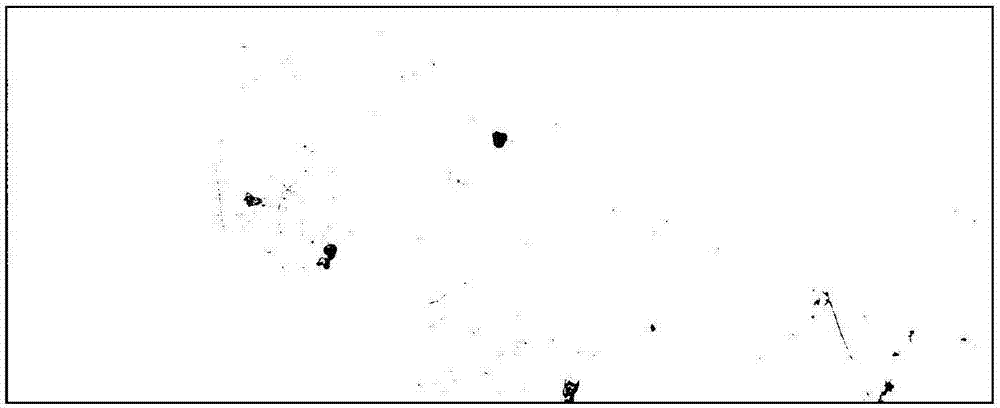

[0035] Step 2: Invert the image. If the gray value of the damage is higher than the background value, the gray image I is inverted.

[0036] Step 3: Threshold initialization. Initialize the binarization threshold t, and calculate the probability statistics value P of the image 0 (t).

[0037]

[0038] Among them, p i is the probability of gray value i, p i =n i / N, where ni is the number of pixels with gray value i in the image, and N is the number of pixels in the entire image.

[0039] Step 4: Calculate the av...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com