Monovinylarene-conjugated diene copolymer, preparation method thereof, random linear copolymer, vulcanized rubber and application

A technology of monovinylarene and conjugated diene, which is applied in the field of monovinylarene-conjugated diene copolymer and its preparation and random linear copolymer and composition and vulcanized rubber, which can solve the problems affecting the damping reduction of products. The application of seismic materials, low damping value, etc., to achieve good damping performance and wide damping temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0126] The polymerization reaction was carried out in a 5-liter stainless steel stirred reactor, and the specific operations were as follows.

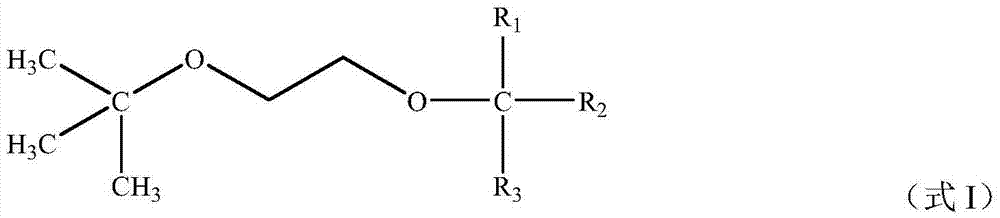

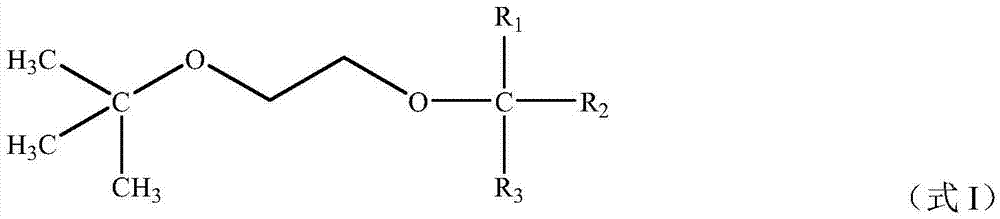

[0127](1) Under the protection of high-purity nitrogen, add 2288g of mixed solvent (the mixed solution of cyclohexane and normal hexane, the mass ratio of cyclohexane / normal hexane is 82 / 18), 64g of styrene (denoted as St, below same) and 190g butadiene (referred to as Bd, the same below), then add 3.66mmol of 1,2-di-tert-butoxyethane (represented as A, A / Li=1, molar ratio), open the reactor Stir (rotating speed is set at 200rpm) to mix the materials evenly. Afterwards, the reaction material was heated with a circulating water bath. When the temperature in the reactor rose to 25°C, the n-butyllithium initiator was used to kill impurities, and then 3.66mmol of n-butyllithium was added to initiate polymerization. During the polymerization reaction, The reaction heat was not removed and the pressure was controlled at 0.2 MPa, and the rea...

Embodiment 2

[0140] The polymerization reaction was carried out in a 5-liter stainless steel stirred reactor, and the specific operations were as follows.

[0141] (1) under the protection of high-purity nitrogen, add 2288g mixed solvent (being the mixed solution of hexanaphthene and n-hexane, the mass ratio of hexanaphthene / n-hexane is 90 / 10), 64g styrene (that is, St) and 190g of butadiene (i.e., Bd), then add 5.78mmol of 1,2-di-tert-butoxyethane (referred to as A, A / Li=1.5, molar ratio), open the reactor and stir (rotating speed is set at 200rpm) to mix the material evenly. Afterwards, the reaction material was heated with a circulating water bath. When the temperature in the reactor rose to 35°C, the n-butyllithium initiator was used to kill impurities, and then 3.97 mmol of n-butyllithium was added to initiate polymerization. During the polymerization reaction, The reaction heat was not removed and the pressure was controlled at 0.2 MPa, and the reaction was carried out for 60 minute...

Embodiment 3

[0144] The polymerization reaction was carried out in a 5-liter stainless steel stirred reactor, and the specific operations were as follows.

[0145] (1) under the protection of high-purity nitrogen, add 2288g mixed solvent (being the mixed solution of hexanaphthene and n-hexane, the mass ratio of hexanaphthene / n-hexane is 82 / 18), 51g styrene (that is, St) and 203g of butadiene (i.e., Bd), then add 4.81mmol of 1,2-di-tert-butoxyethane (referred to as A, A / Li=1.2, molar ratio), open the reactor and stir (rotating speed is set at 200rpm) to mix the material evenly. Afterwards, the reaction material was heated with a circulating water bath. When the temperature in the reactor rose to 50°C, the n-butyllithium initiator was used to kill impurities, and then 3.87mmol of n-butyllithium was added to initiate polymerization. During the polymerization reaction, The temperature in the reactor was controlled to be 50° C. and the pressure was controlled to be 0.2 MPa, and the reaction wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| dielectric loss factor | aaaaa | aaaaa |

| dielectric loss factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap