Mounting structure of detergent dispenser

A detergent injection and installation structure technology, applied in the field of washing machines, can solve the problems of uneven force on the water storage box, messy feeling of the user as a whole, and safety, and achieve the effects of good intuitive feeling, reduced quantity, and reduced possibility of fire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

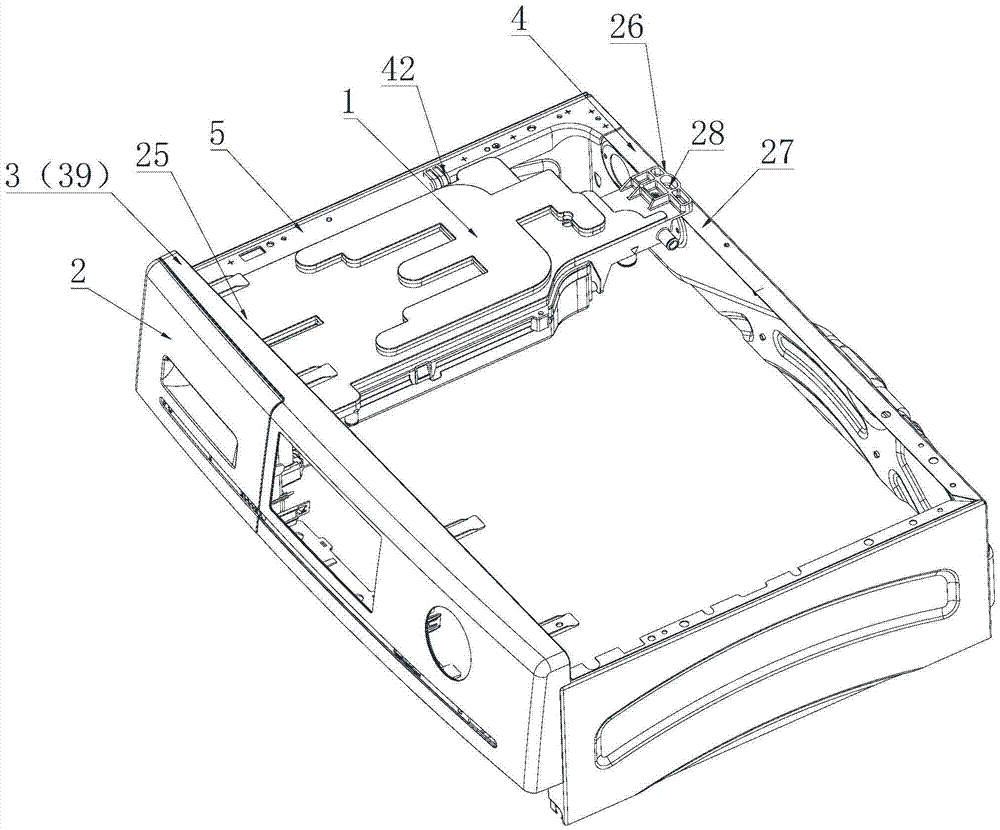

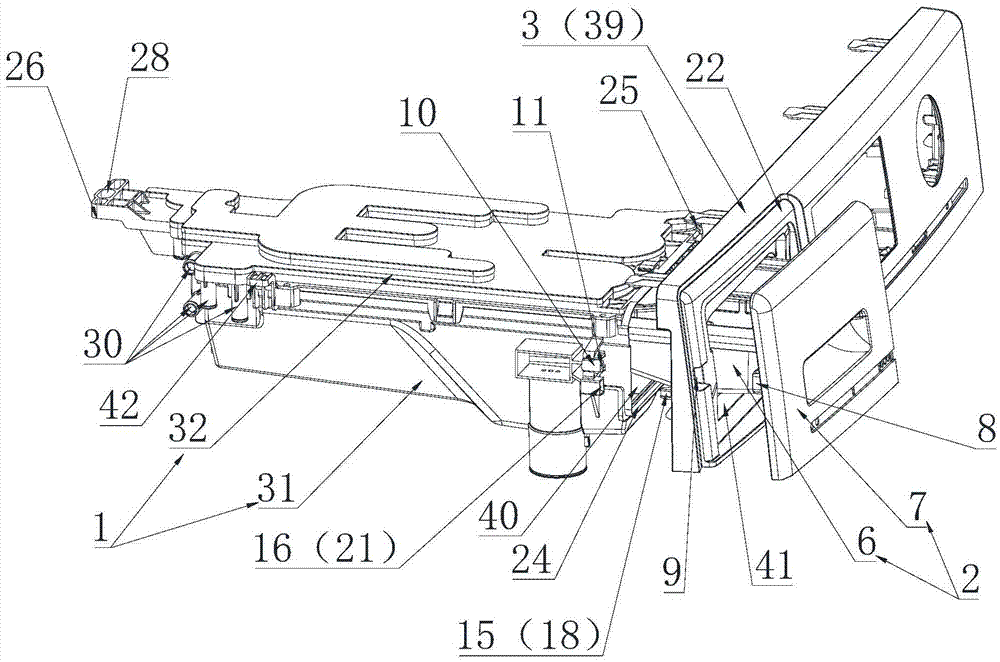

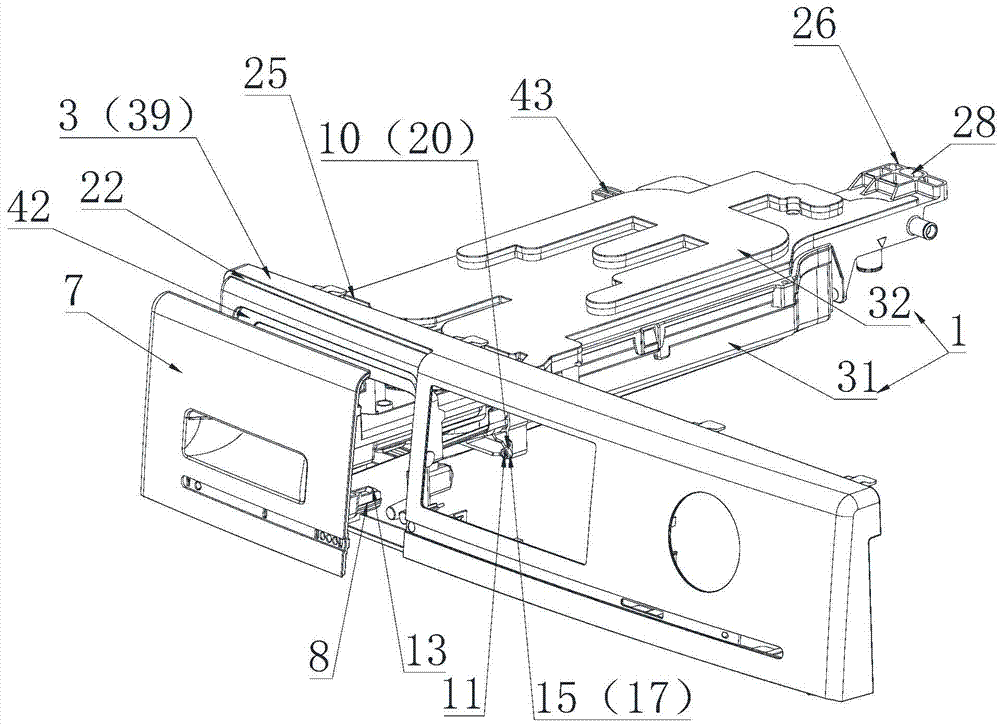

[0029] The installation structure of a detergent dispenser according to the present invention comprises: a water storage box 1, a drawer assembly 2 that can be pushed in and out of the water storage box, and the water storage box 1 is installed in the upper part of the box and the box. The body front plate 3 is matched, and the inlet and outlet 44 of the drawer assembly 2 are provided at the matching position. The water storage box 1 is provided with a first opening 40 corresponding to the box body front plate 3, and the box body front plate 3 is provided with a second The opening 41, the first opening 40 and the second opening 41 form an inlet and outlet 44 of the drawer assembly 2 through the inlet and outlet 44, the drawer assembly 2 enters and exits the water storage box 1 through the inlet and outlet 44, and pulls out the water storage box 1 and then faces the drawer assembly 2 add detergent, push the rear drawer assembly 2 of the water storage box 1 to cooperate with the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com