Inner barrel for dewatering machine

A dehydrator and inner cylinder technology, applied in the field of mechanical washing, can solve the problems of easy damage, poor drainage effect, increase production and living costs, etc., and achieve the effect of rationally integrating resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further explained below in conjunction with the accompanying drawings and embodiments.

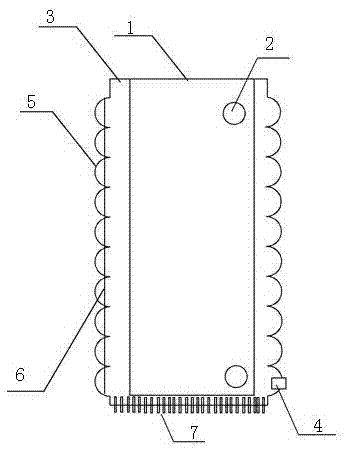

[0013] Such as figure 1 As shown, an inner cylinder for a dehydrator includes an inner cylinder body 1, a water outlet hole 2 provided on the inner cylinder body 1, a water collection bucket 3 sleeved outside the inner cylinder body 1, and a drainage tube provided on the water collection bucket 3. The hole 4 is provided with a drainage groove 5 on the water collecting bucket 3, and the drainage groove 5 is matched with the drainage hole 4.

[0014] The water collecting bucket 3 is provided with several support columns 6 . Drain hole 4 is provided with at least three. The bottom surface of the water collecting bucket 3 is provided with a heat radiation fin layer 7 .

[0015] The above content is an example and description of the present invention, but it does not mean that the advantages that the present invention can obtain are limited by this, any s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com