Oscillating arm type bulkhead gate locking mechanism driven by hydraulic cylinders

A flat gate and locking mechanism technology, applied in water conservancy engineering, marine engineering, coastline protection and other directions, can solve problems such as accidents, gate falling, and high parking accuracy requirements, and achieve the effect of reliable technology and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation to the present invention, they are only examples, and at the same time, the advantages of the present invention will become clearer and easier to understand.

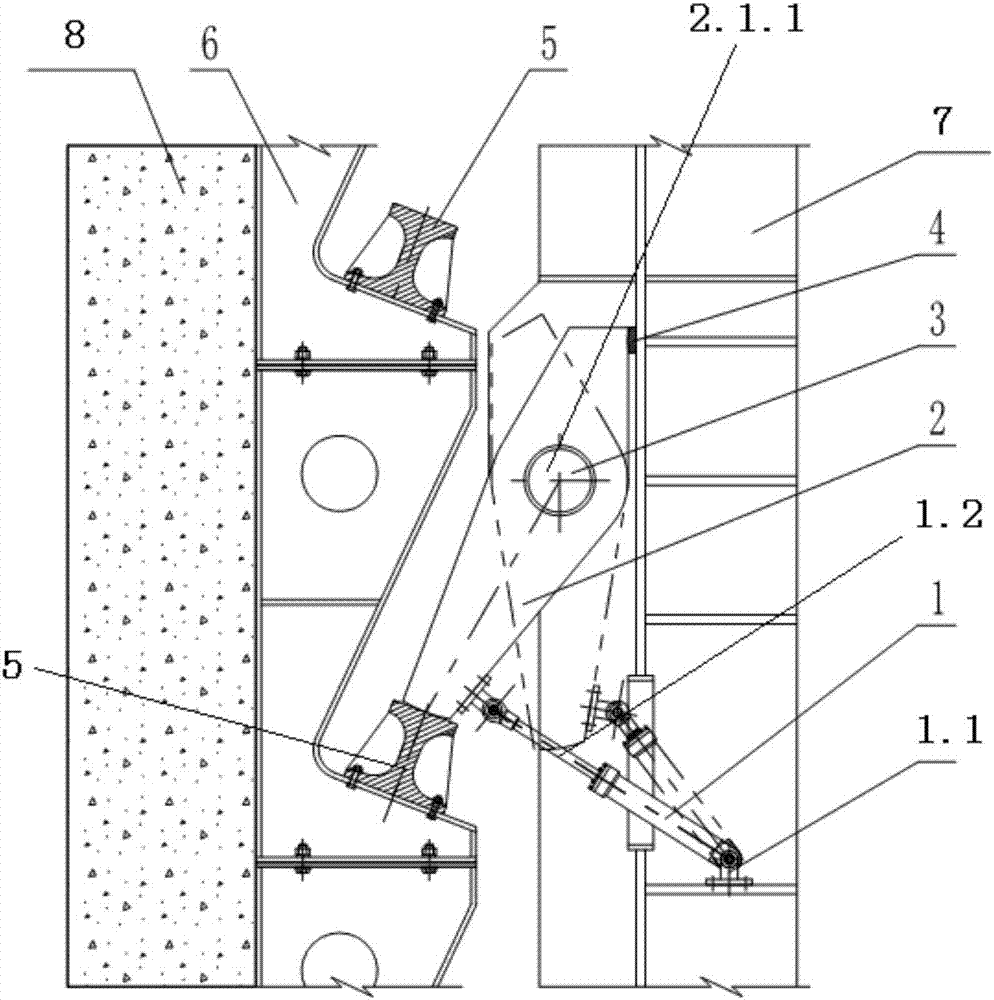

[0014] refer to figure 1 Shown: a swing arm type flat gate locking mechanism driven by hydraulic cylinders, the body 7 of the swing arm type flat gate locking mechanism driven by several hydraulic cylinders is arranged in sequence along the longitudinal direction, and the swing arm type driven by each hydraulic cylinder The plate gate locking mechanism body 7 includes a driving cylinder 1, a swing arm 2, a locking shaft and a shaft sleeve 3, a support block 4, a locking support track 5, a stepped locking frame 6 and a driving cylinder hinge seat 7; Located below the swing arm 2, the tail of the driving cylinder 1 is hinged to the gate side column hing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com