A suspended type fully enclosed slag removal system

A fully enclosed and suspended technology, applied in mechanical removal operations, in the field of suspended fully enclosed one-way continuous slag removal system, can solve the problems of high production cost and inability to overcome the slag jamming of the two-way chain, so as to achieve low loss and overcome slag jamming. The problem, the effect of overcoming gravity to tighten the chain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

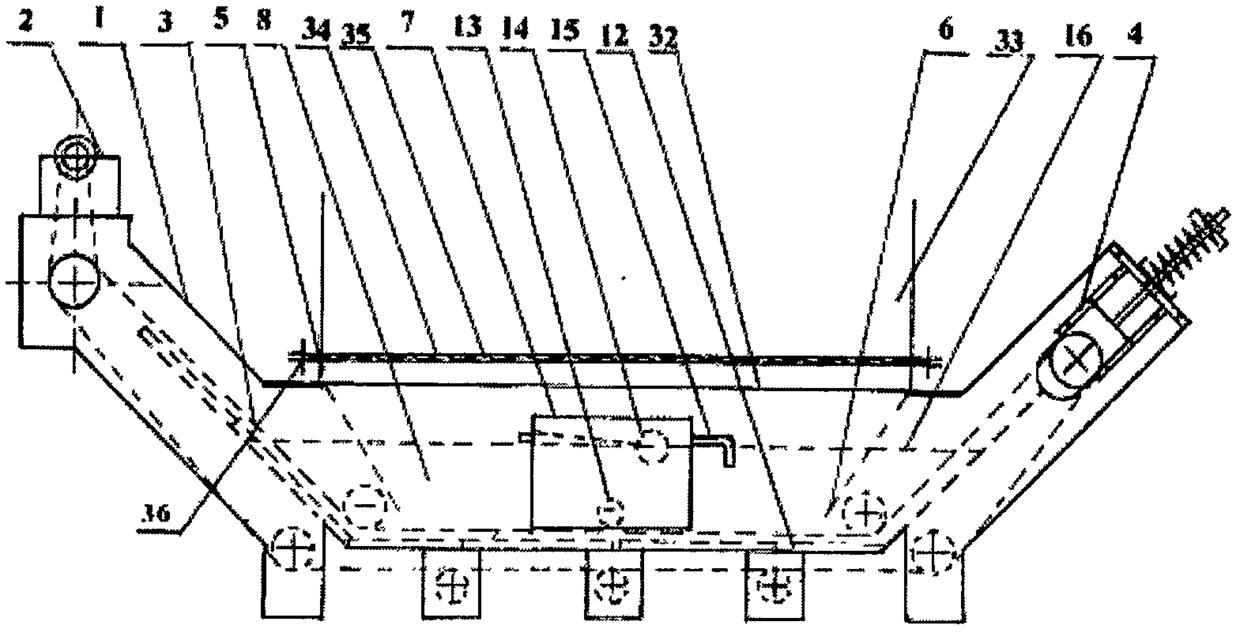

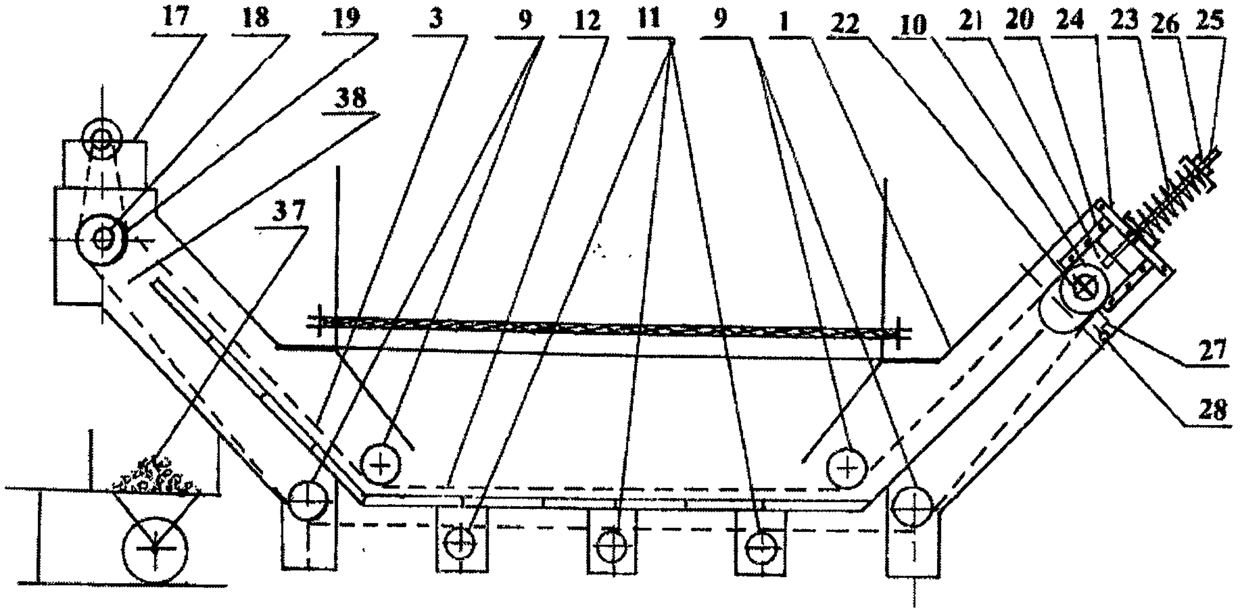

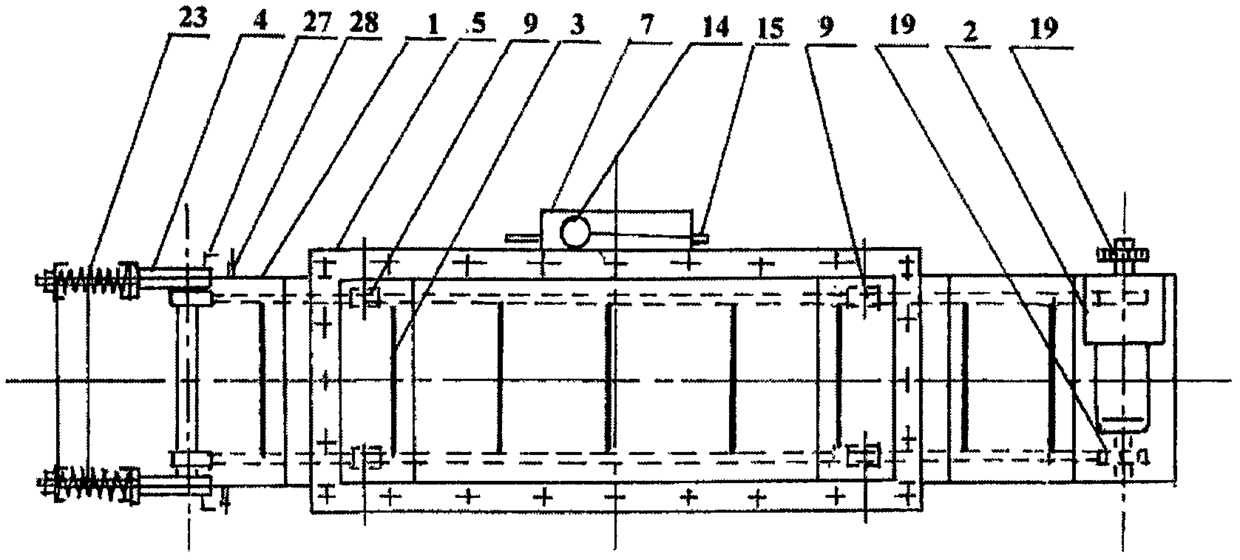

[0018] combined with figure 1 , 3 It can be seen that the fully enclosed one-way continuous slag removal system of the present invention is mainly composed of a slag removal tank, a power unit, a scraper chain, a fastening and automatic protection device, a suspension device, a water seal partition and a water supply tank, wherein the slag removal Slot 1 is a ship-shaped box with two ends upturned, open at the top, and closed all around. One end is provided with a power device 2 that drives the movement of the scraper chain 3; the other end is provided with a chain fastening and automatic protection device for fastening the chain. 4. A suspension device 5 is provided on the upper open part of the slag removal tank 1; a water body 8 is filled in the closed box of the slag removal tank, and a water seal partition 6 is provided; On the board, a hole 13 is opened at the bottom of the water replenishment tank 7, so that the water body 8 in the replenishment water tank 7 and the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com