Three-dimensional knitting equipment

A three-dimensional weaving and three-dimensional technology, applied in the direction of fabrics, textiles, looms, etc., can solve the problems of difficulty in removing or adding yarn, and the yarn carrier cannot achieve free movement, etc., to achieve easy processing, convenient installation and disassembly, and guarantee. effect of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The embodiments of the present invention will be further described below in conjunction with the drawings.

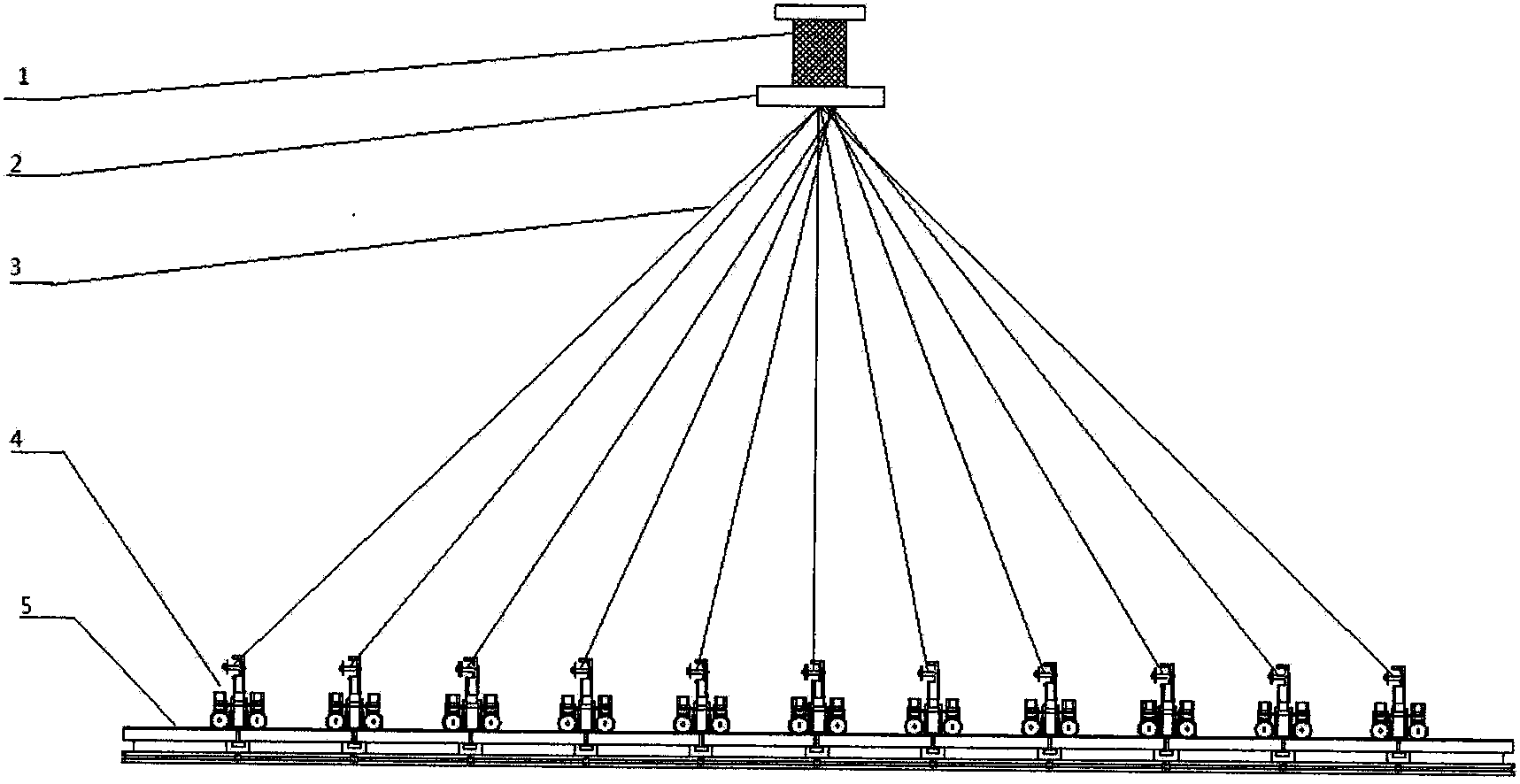

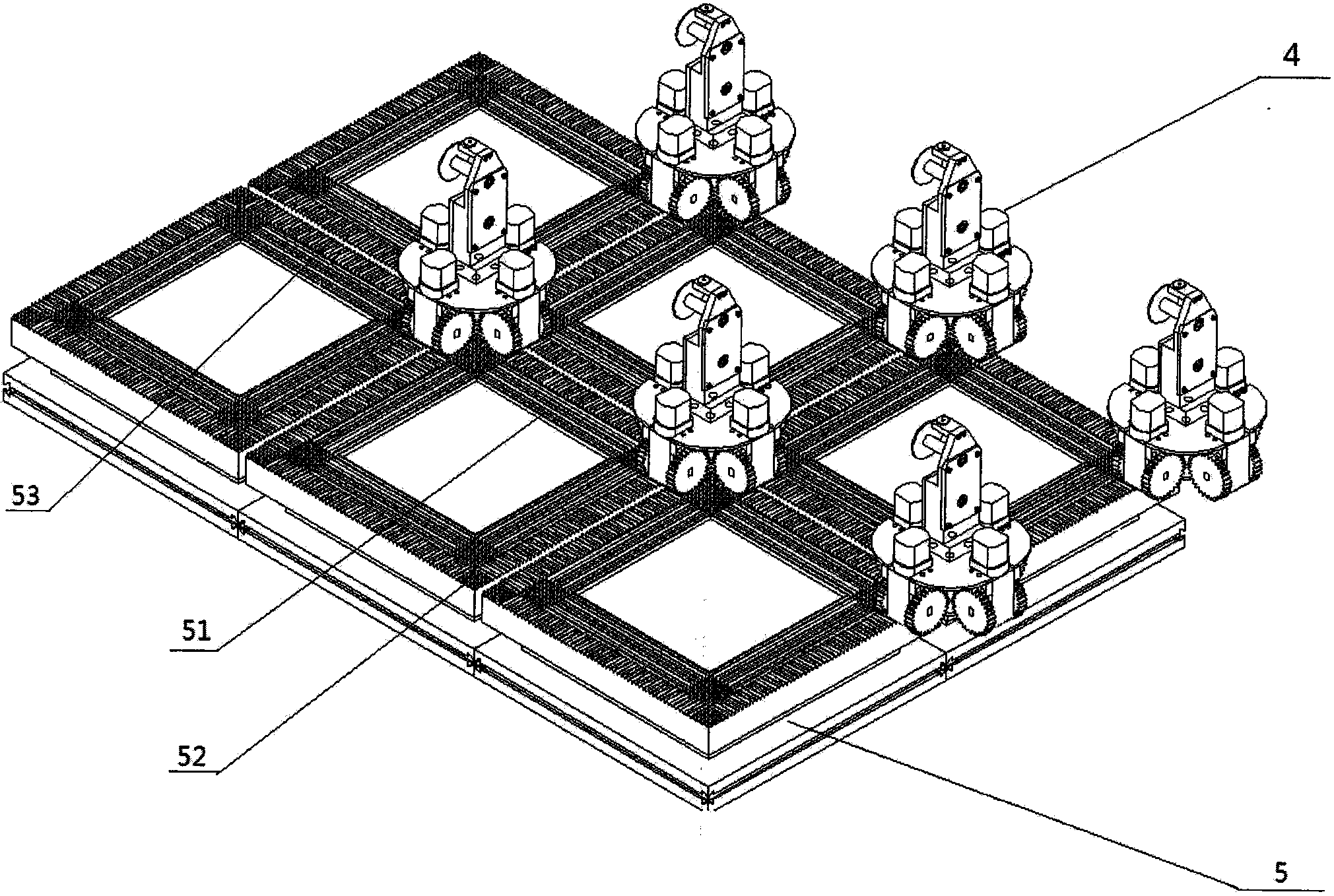

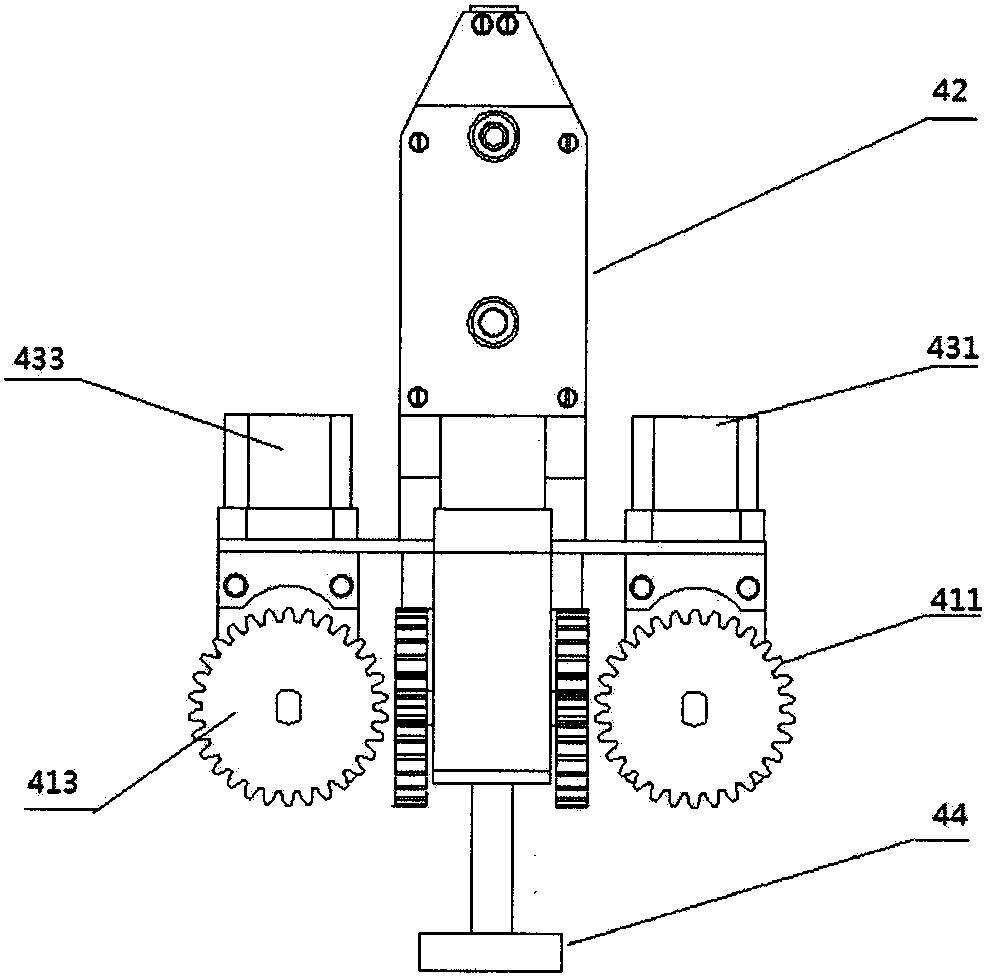

[0025] The overall picture of the three-dimensional braiding equipment is as figure 1 Shown. In the overall view, 1 is a three-dimensional braiding preform, 2 is a forming device, 3 is a knitting yarn, 4 is a gear-type active yarn carrier, and 5 is a rack-type knitting chassis. The gear-type active yarn carrier 4 is equipped with four DC motors, and each DC motor drives a pair of gears respectively, and there are a total of four pairs of gears. Each pair of gears are coaxial, with two DC motors in the X-axis direction and two DC motors in the Y-axis direction. In this way, the movement in each dimension is powered by two DC motors, and the gear-type active yarn carrier 4 is directly placed on the chassis composed of racks, and the two sets of racks on the chassis are arranged at equal intervals.

[0026] The knitting yarns are carried by the yarn carrier and arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com