A system that facilitates rapid detection of hob wear

A technology of wear degree and hob, which is applied in the system field of rapid detection of hob wear degree, and can solve the problems that the detection and tool change time should not be too long, affect the speed of shield tunneling tool change, and increase the safety hazards of workers, etc. , to achieve the effect of solving the risk of manual inspection, strong practicability, and reducing potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

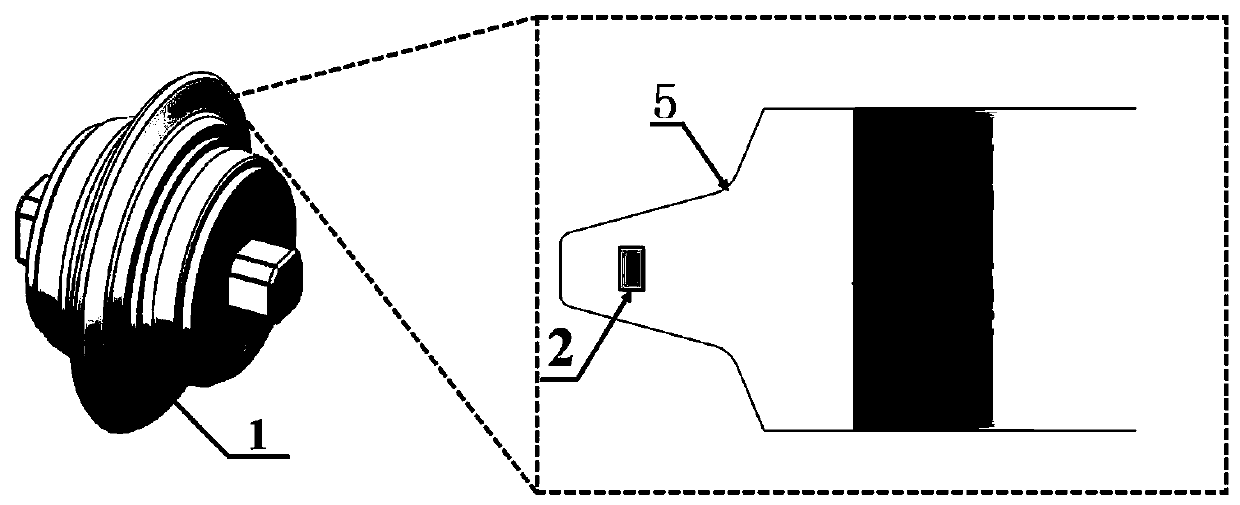

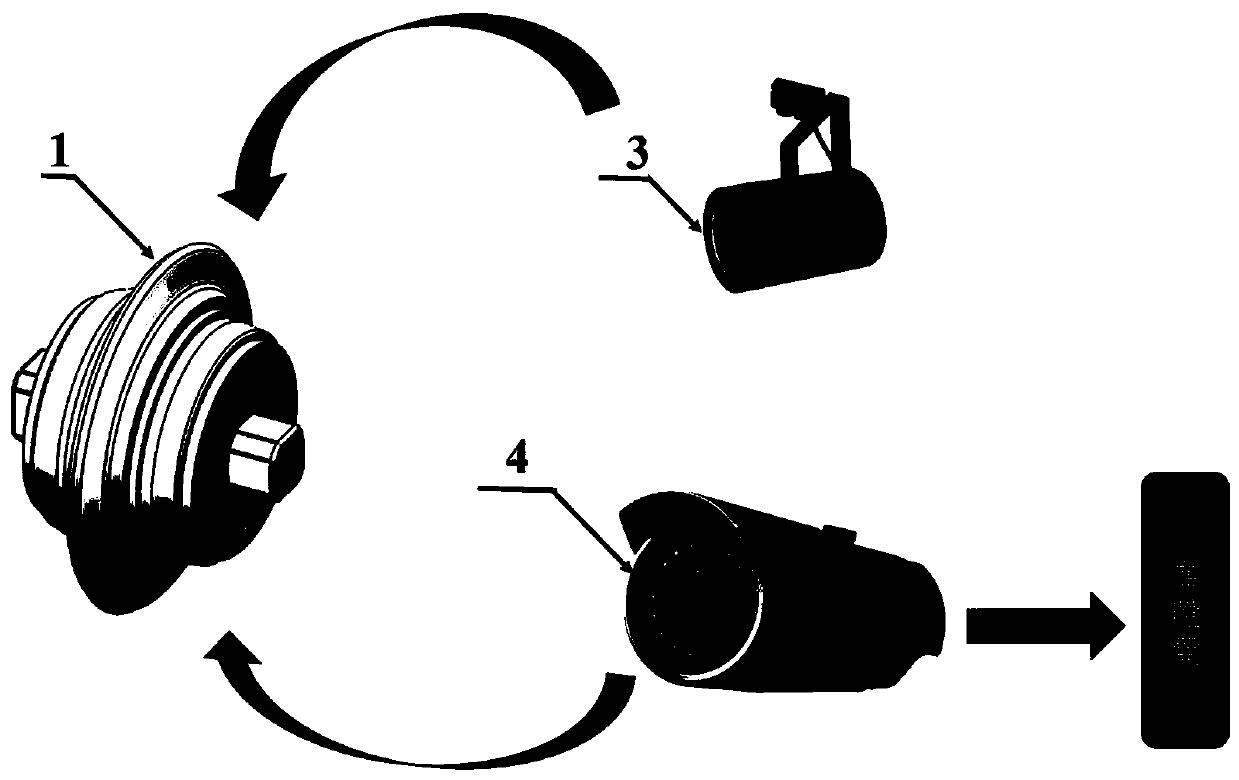

[0036] Such as figure 2 As shown, the present invention discloses a system for quickly detecting the degree of hob wear, comprising a disc-shaped hob 1, an oxygen-nitrogen system green fluorescent powder 2 placed in the knife ring of the disc-shaped hob (1), cross-assembled on The Ziguang chip and cutterhead hob monitoring system under the front shield; the disc-shaped hob is installed at the corresponding position of the shield machine or TBM hard rock tunneling machine; the Ziguang chip is placed under the front shield for protection, and uniformly distributed around the front shield. The cutter head and hob monitoring system is also evenly distributed under the front shield, and arranged crosswise with the purple LED chips;

[0037] The disc-shaped hob cutter ring of the detection system adopts an internal groove design, and the width and depth of the groove are respectively 1 / 10 of the hob blade width and cutter ring diameter;

[0038] Under the irradiation of the BaSiO...

Embodiment 2

[0041] Such as figure 2 As shown, the present invention discloses a device system for quickly detecting the degree of hob wear, comprising a disc-shaped hob 1, an oxygen-nitrogen system green fluorescent powder 2 placed in the ring of the disc-shaped hob 1, cross-assembled in the front The Ziguang chip and cutterhead hob monitoring system under the shield; the disc hob is installed at the corresponding position of the shield machine or TBM hard rock tunneling machine; the Ziguang chip is placed under the front shield for protection, and uniformly Distributed around the front shield. The cutter head and hob monitoring system is also evenly distributed under the front shield, and arranged crosswise with the purple LED chips;

[0042] The disc-shaped hob cutter ring of the detection system adopts an internal groove design, and the width and depth of the groove are respectively 1 / 9 of the hob blade width and cutter ring diameter;

[0043] Under the irradiation of the BaSiON:Eu ...

Embodiment 3

[0046] Such as figure 2 As shown, the present invention discloses a device system for quickly detecting the degree of hob wear, comprising a disc-shaped hob 1, an oxygen-nitrogen system green fluorescent powder 2 placed in the ring of the disc-shaped hob 1, cross-assembled in the front The Ziguang chip and cutter head hob monitoring system under the shield; the disc hob is installed at the corresponding position of the shield machine or TBM hard rock tunneling machine. The purple light chip is placed under the front shield for protection, and is evenly distributed around the front shield. The cutter head and hob monitoring system is also evenly distributed under the front shield, and arranged crosswise with the purple LED chips;

[0047] The disc-shaped hob cutter ring of the detection system adopts an internal groove design, and the width and depth of the groove are respectively the width of the hob blade and the diameter of the cutter ring 1 / ;

[0048]Under the irradiatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| spectroscopy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com