Rotary type variable resistor

A resistor and rotary technology, applied in the direction of adjustable resistors, resistors, sliding contact resistors, etc., can solve problems such as difficult production, increased cost, and limited rotation angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

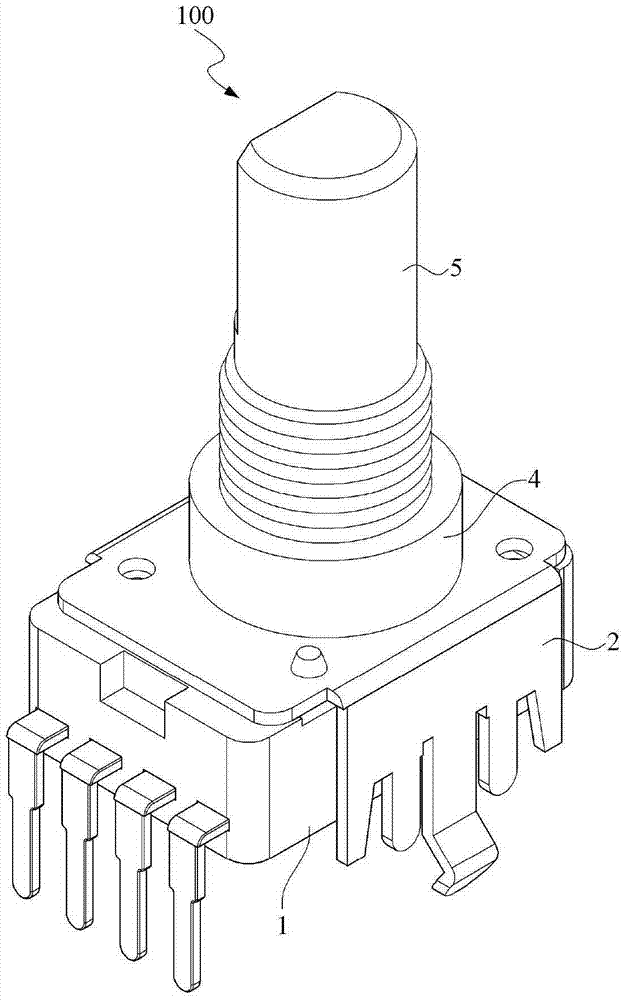

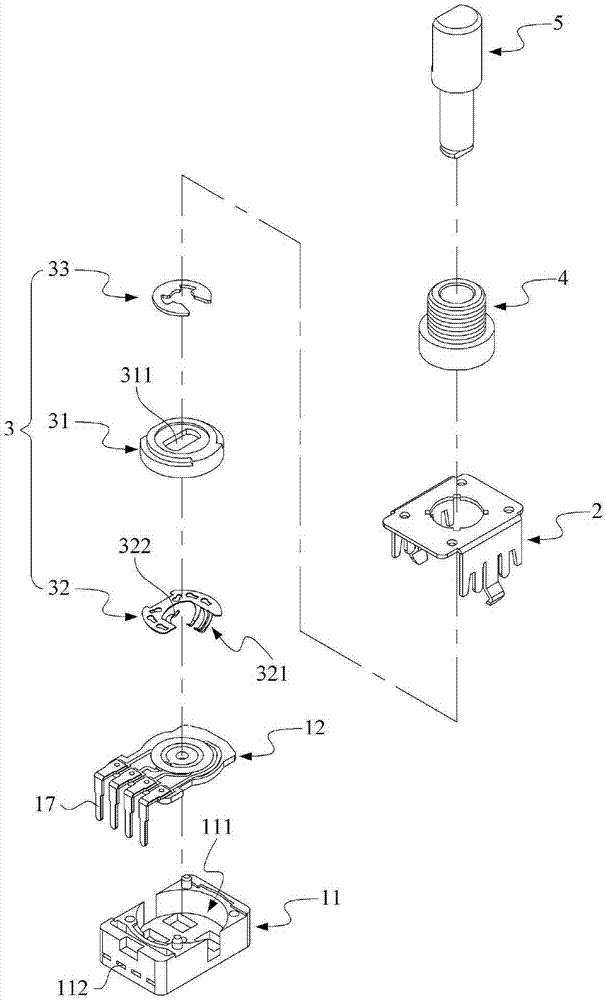

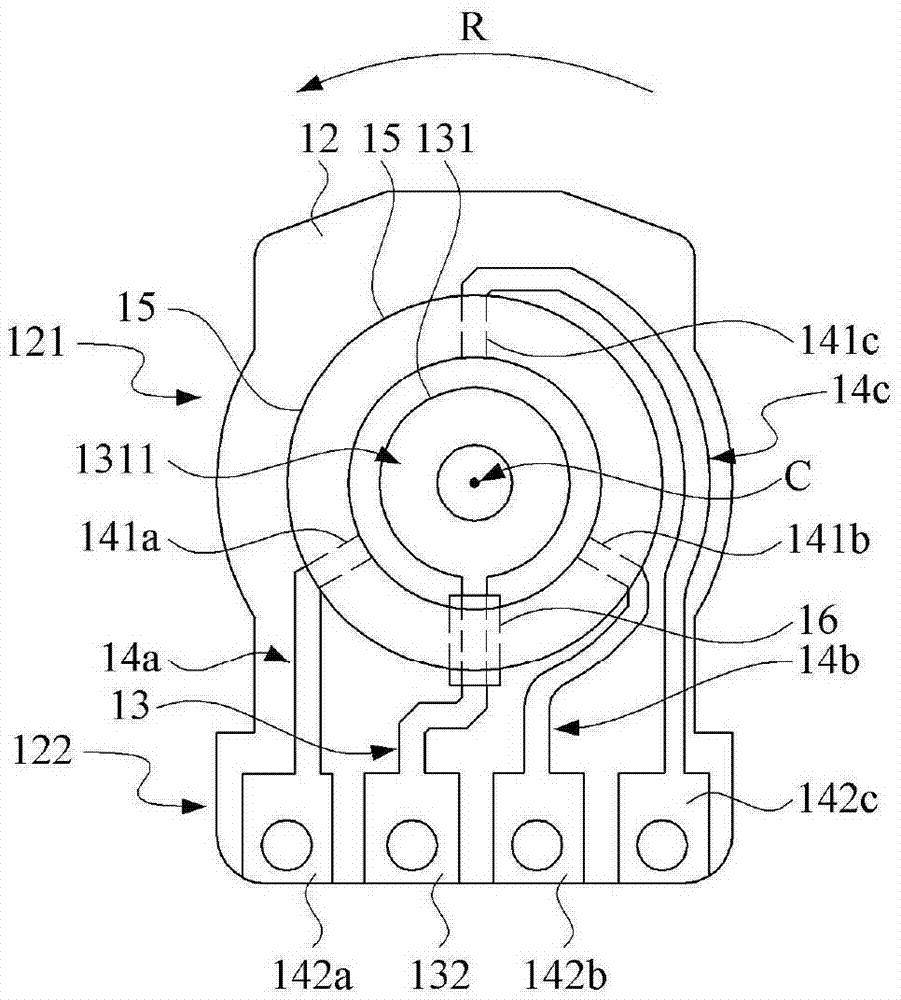

[0048] see Figure 1 to Figure 4 , figure 1 A three-dimensional schematic diagram showing a rotary variable resistor provided by a preferred embodiment of the present invention; figure 2 A three-dimensional exploded schematic diagram showing a rotary variable resistor provided by a preferred embodiment of the present invention; image 3 A schematic plan view showing a resistive circuit module provided by a preferred embodiment of the present invention; Figure 4 A schematic circuit diagram of a resistance circuit module provided by a preferred embodiment of the present invention is shown.

[0049] Such as Figure 1 to Figure 4 As shown, a rotary variable resistor 100 includes a resistor circuit module 1 , a fixing frame 2 , a brush assembly 3 , a bushing 4 and a shaft 5 .

[0050] The resistance circuit module 1 comprises an insulating base 11, a circuit substrate 12, an output circuit 13, three input circuits 14a, 14b, 14c, a ring-type resistance layer 15, an insulating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com