Improved damped rotation type charge level indicator and material level judgment method

A material level meter and material level technology, which is applied in the field of powder measurement, can solve the problems of broken hammer, buried hammer, and inability to accurately determine the material level, and achieve the effect of improving the accounting efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

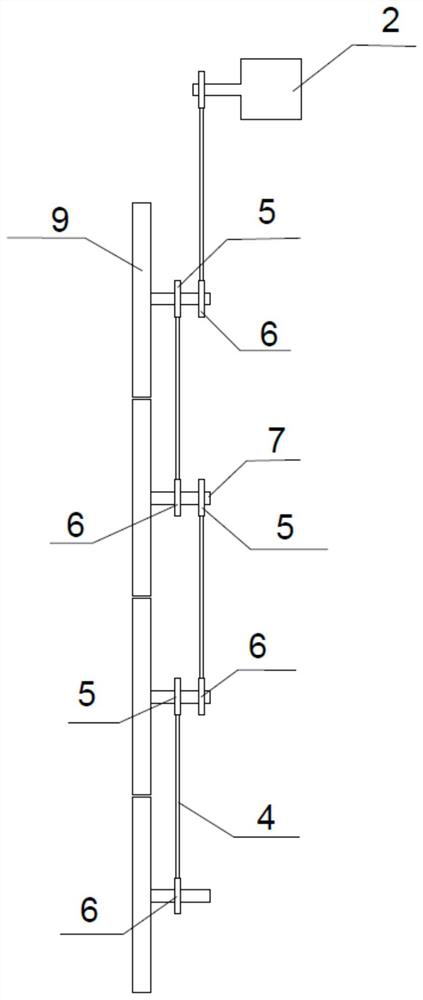

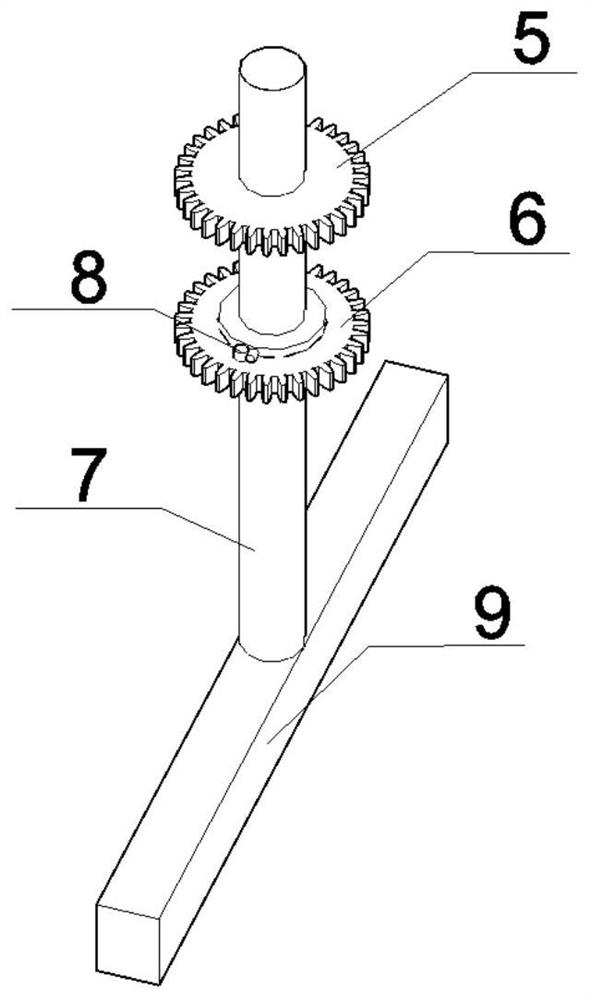

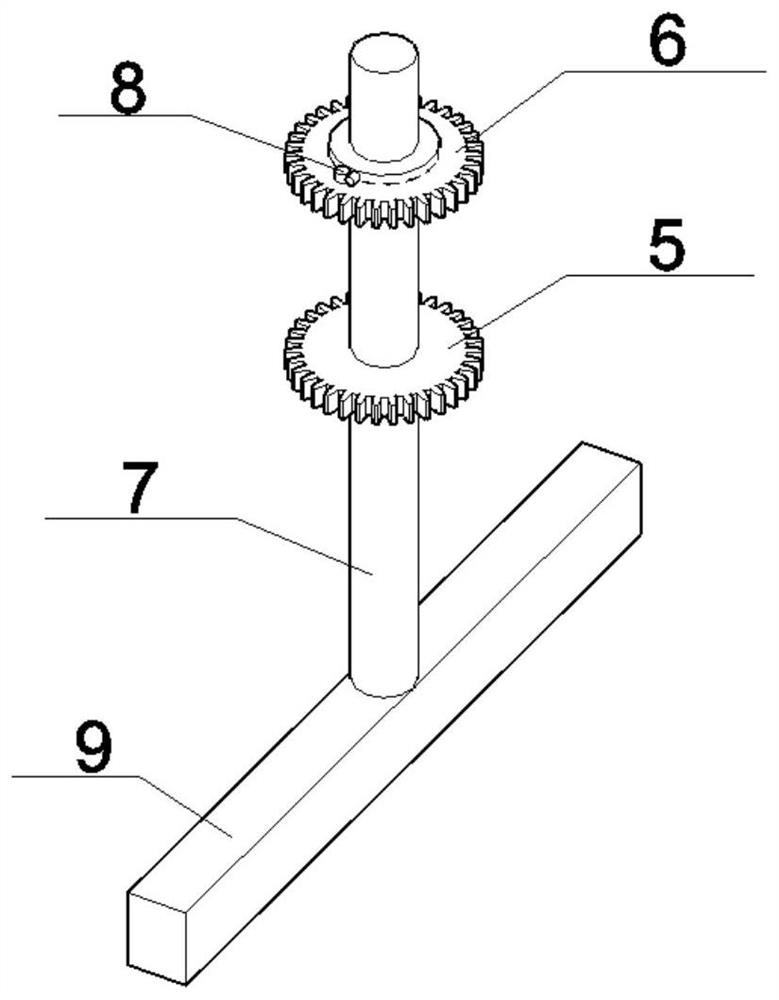

[0027] This embodiment provides an improved sealing material disconnection, including processor 1, a sealing motor 2, a powder bin 3, a transmission chain 4, a transmission mechanism, a rotating blade 9, and a sealing box 10. The processor 1 is electrically connected to the spinning motor 2, and the output signal of the blotting motor 2 to the processor 1 includes the number of rotation rings and the torque shift amount, and the spinning motor 2 is located at the top, resistance of the powder bin 3. The rotary motor 2 is a two-way rotary motor. The processor 1 can determine the material according to the signal (including the number of rotation rings, the number of working torque values) transmitted according to the semicocular 2, wherein the number of rotation of the rotation motor 2 is initially judged, and then then Calculate the size of the torque enhancement based on the operation. The blocker motor 2 can transmit the signal to the processor 1 in real time, and the processor 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com