Control method and control apparatus for magnetic force operating mechanism

A technology of an operating mechanism and a control method, which is applied to high-voltage air circuit breakers, electrical components, electrical switches, etc., can solve the problems of low buffering efficiency, low reliability, and poor controllability of spring buffering characteristics, so as to reduce bounce and rebound. , the effect of reducing mechanical impact and reducing movement speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

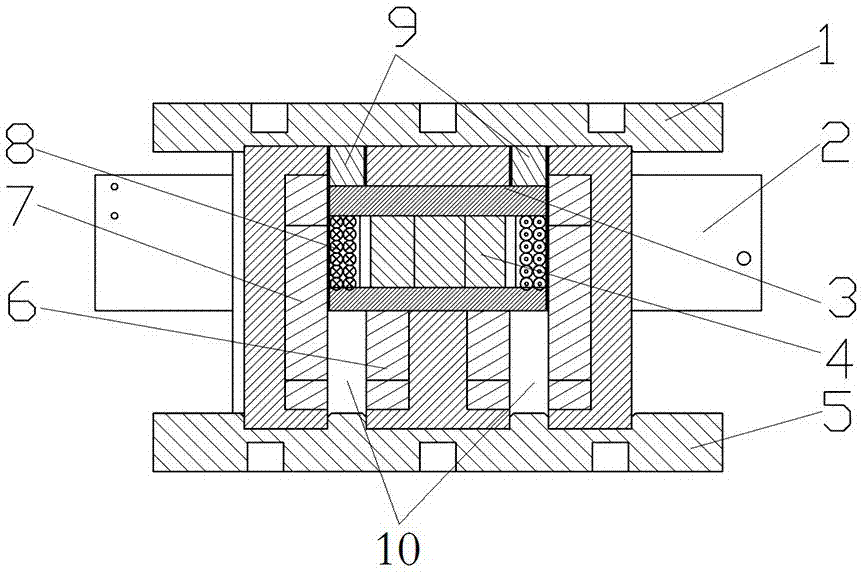

[0024] Such as figure 1 and figure 2 As shown, the magnetic operating mechanism includes a mechanism frame, and the mechanism frame includes a plurality of columns arranged at intervals extending in the up and down direction, an upper cover plate 1 and a lower bottom plate 5 fixed at both ends of the columns, and a mechanism fixed on the outside of the columns. Frame 2, a coil assembly is equipped with a reciprocating movement along the up and down direction on the mechanism frame. The plate 4 and the baffles at both ends form a ring groove, and the electromagnetic coils are correspondingly wound in the ring groove to be fixed on the coil frame 3, and all or part of the coil frame is made of ferromagnetic material, which can play a corresponding role as an iron core.

[0025] Each column of the above-mentioned mechanism frame can be divided into a mid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com