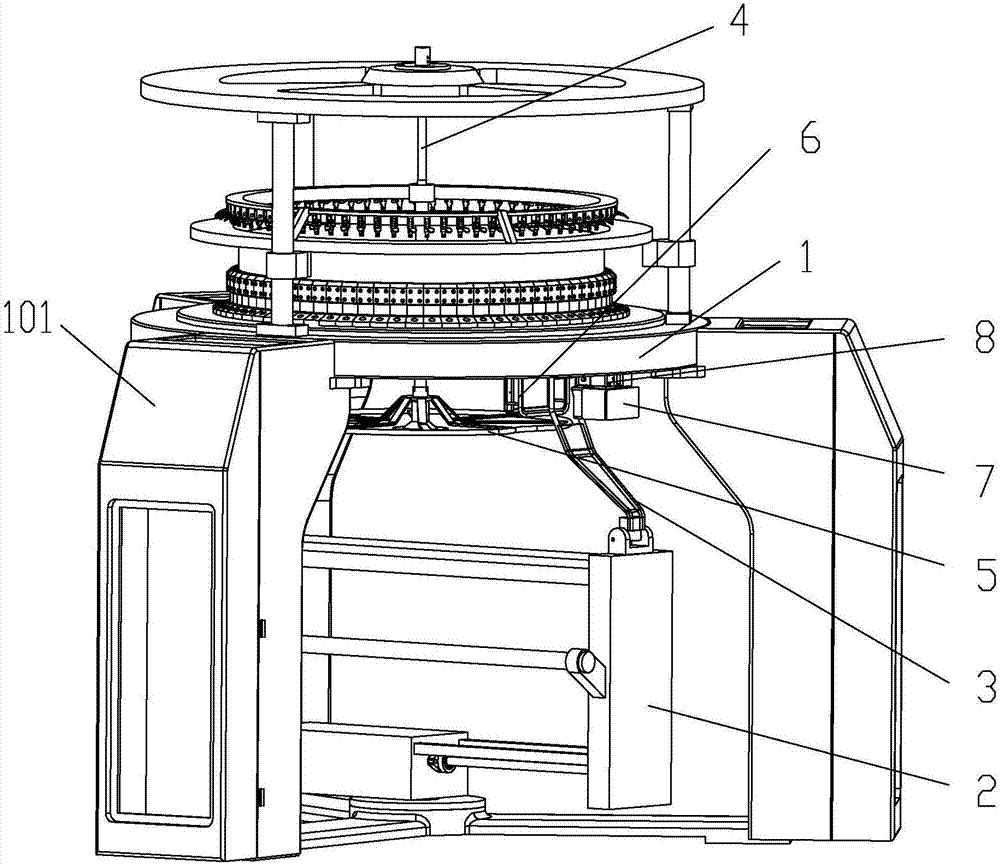

Device and method for acquiring real-time cloth cover image of circular weft knitting machine

A real-time image and acquisition device technology, applied in the field of knitting machinery, can solve the problems of inconsistent light and shade, missed cloth, unclear and consistent texture, etc., to achieve the effect of clear and consistent texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

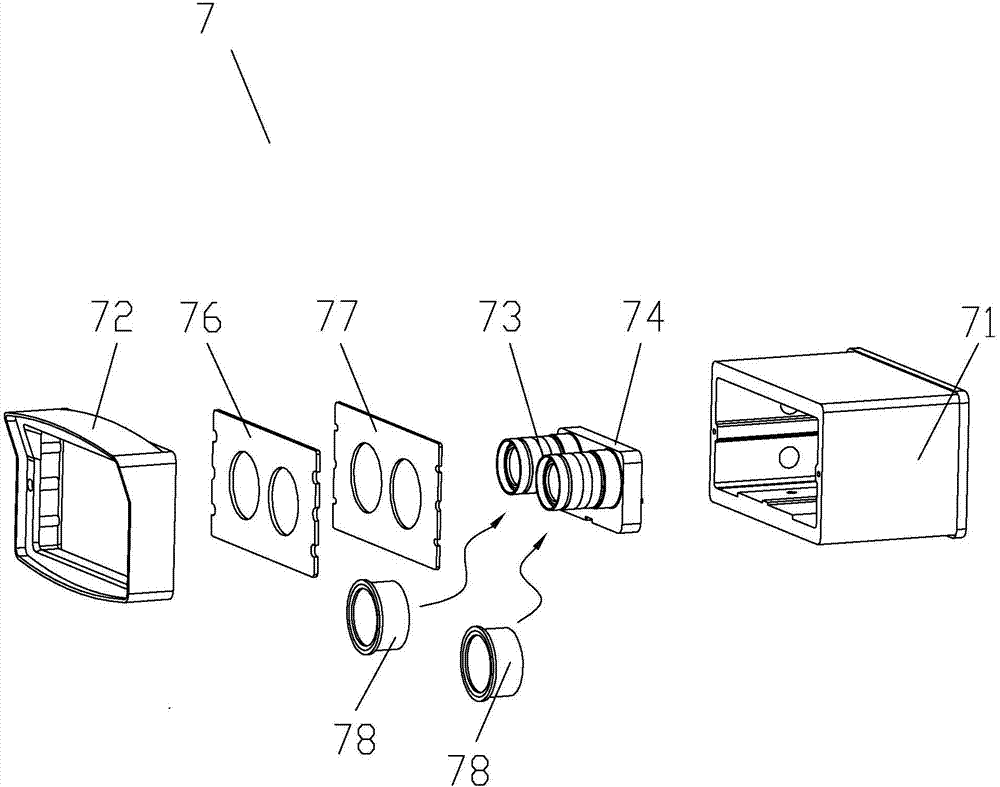

[0032] In order to avoid missed inspection of the cloth surface, based on step 1, the first implementation method is provided. The original cloth roll rack linkage rod 3 is replaced with an open cloth roll rack linkage rod 3, which is generated when the multi-camera 7 is used to acquire images. Obtain the image of the cloth surface behind the linkage rod 3 of the cloth roll frame by overlapping the viewing angles.

[0033] Provide the second implementation method again, by setting the camera 7 at an included angle, the image of the cloth surface behind the linkage rod 3 of the cloth rolling rack is obtained by overlapping the angles of view generated when the images are obtained by multiple cameras, so as to avoid real-time detection of defective cloth of the circular weft machine The cloth surface in the system has missed detection.

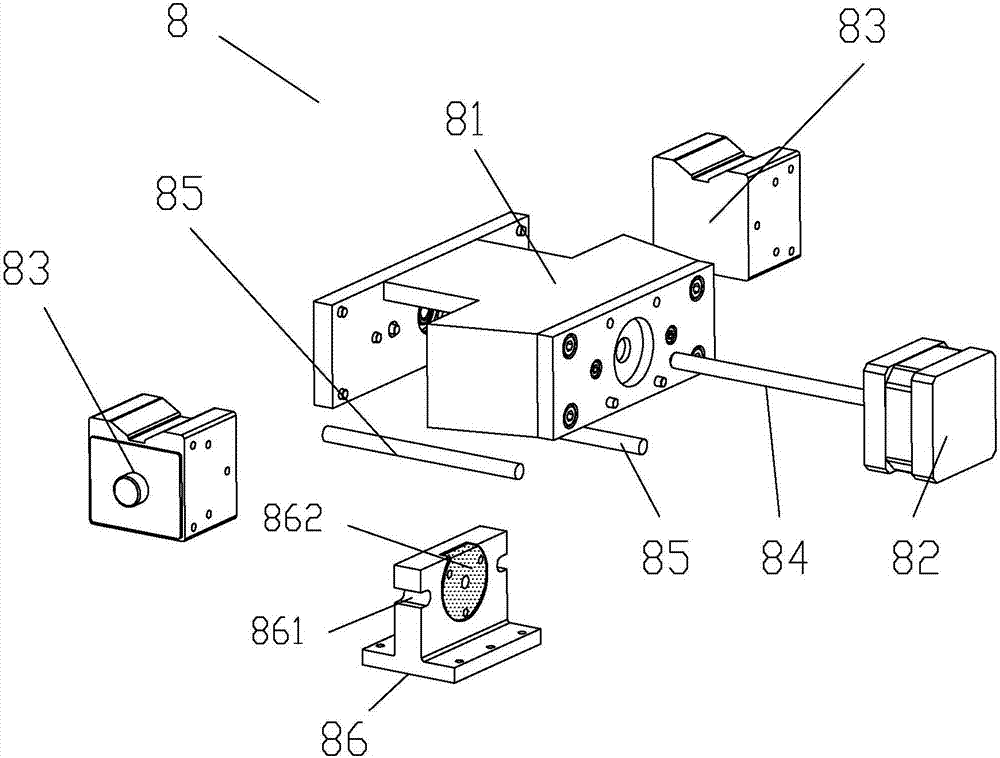

[0034] Provide the first embodiment of the image acquisition device according to the first implementation method in the above image acquisition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com