Shrimp screening machine

A rack and shrimp plate technology, applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of bulky and bulky machines, high vibration noise, poor sorting accuracy, etc., achieve accurate classification, low price, and reduce cleaning the troublesome effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

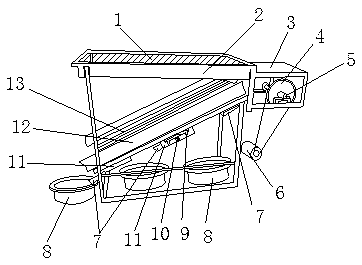

[0018] Such as Figure 1-3 Shown, a kind of shrimp sifting machine comprises frame and the installation frame 3 that is arranged on one side of frame. A storage device is installed on the top of the frame, and a shrimp screening mechanism is arranged on the frame below the storage device. The installation frame 3 is provided with a power unit, and the power unit is connected to the shrimp sifting mechanism through transmission. The shrimp sifting mechanism includes a shrimp sifting tank 12 installed obliquely downward in the frame, and a vibrating screening device is arranged in the shrimp sifting tank 12, and the vibration screening device is connected with a power unit through transmission. The bottom of the vibration screening device is provided with several shrimp sieving plate mechanisms, and a container 8 is arranged below the outlet position of the shrimp sieving plate mechanism, and the container 8 corresponds to the shrimp sieving plate mechanism one by one.

[0019...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com