Valve-spring-free four-stroke engine

A four-stroke engine, valve spring technology, applied in engine components, machines/engines, mechanical equipment, etc., can solve problems such as extra energy consumption of valve springs, and achieve the effects of reducing wear, low production cost, and easy manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

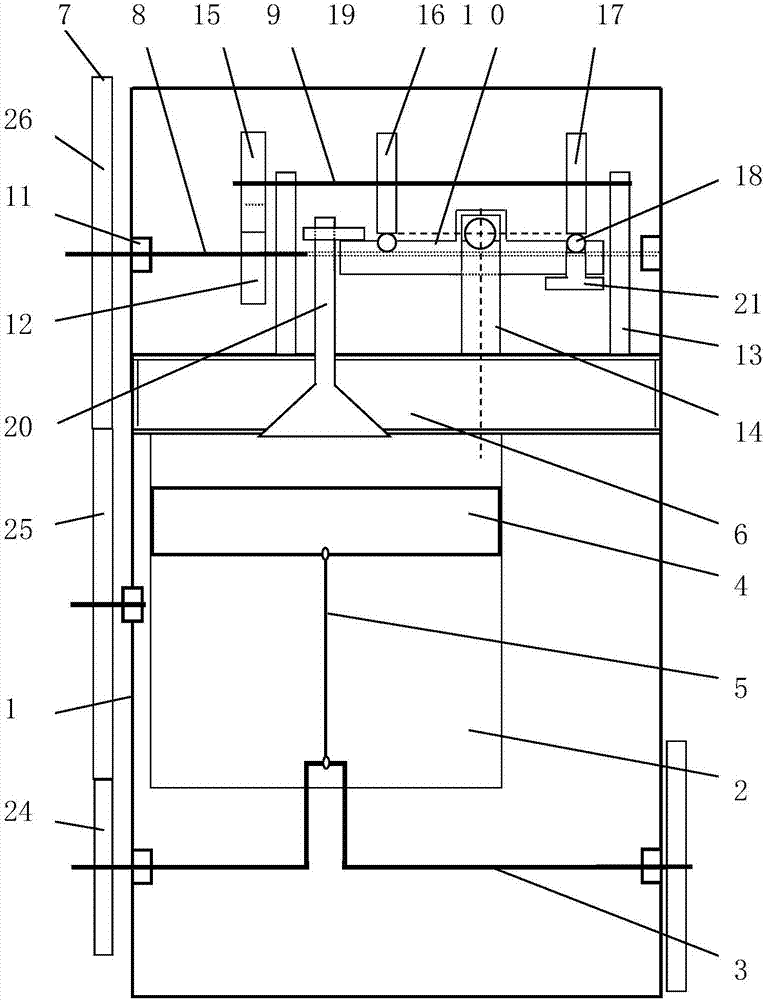

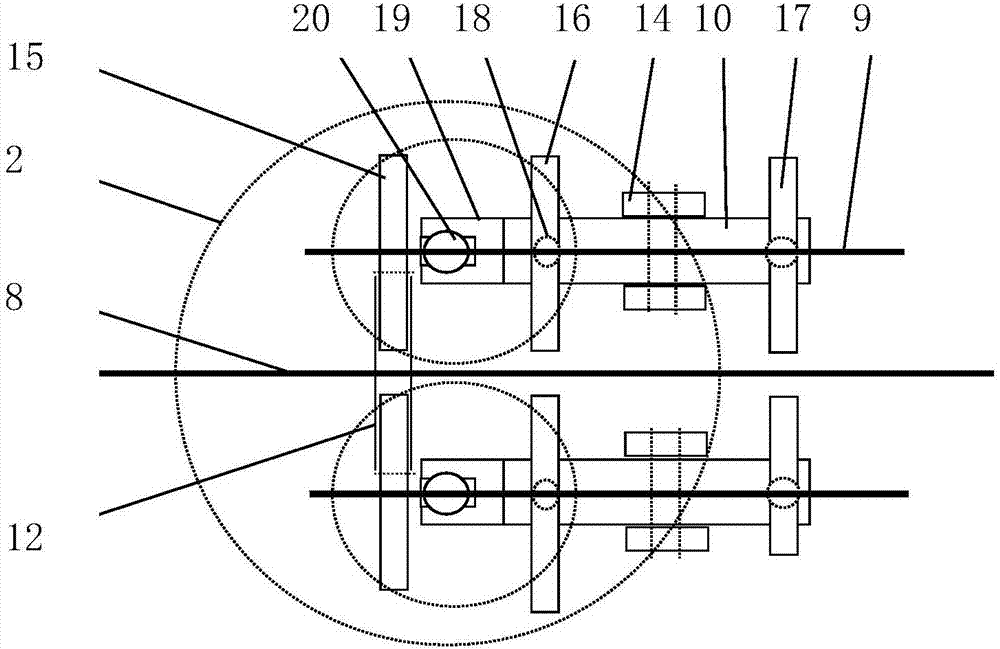

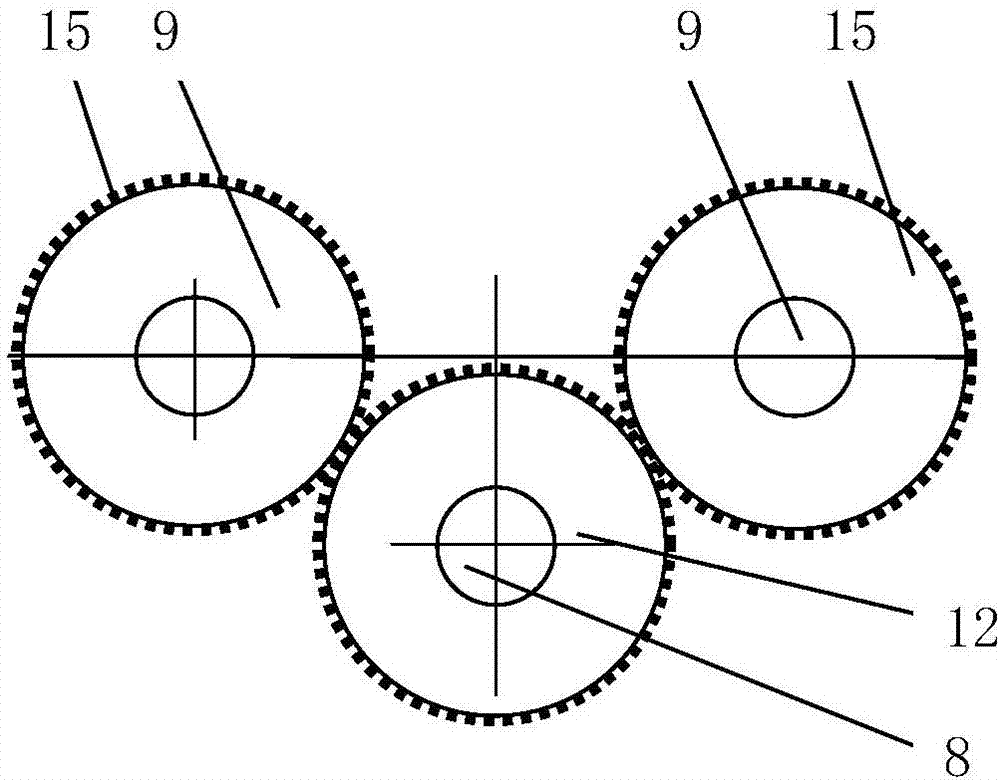

[0026] Such as figure 1 figure 2 image 3 As shown, the four-stroke engine without valve springs includes a cylinder block 1, a cylinder 2, a crankshaft 3, a piston 4, a connecting rod 5, an intake and exhaust chamber 6, and a gear set 7, and the crankshaft 3 drives the valve mechanism through the gear set 7. , characterized in that: the gas distribution mechanism includes a rotor drive shaft 8, a convex-concave rotor 9 and a lever 10; the rotor drive shaft 8 is arranged on the top surface of the intake and exhaust cavity 6 through a bearing frame 11, and a driving gear is arranged on the shaft 12. The top surface of the intake and exhaust chamber 6 is provided with a rotor bracket 13 and a lever bracket 14, and the rotor bracket 13 is provided with two convex-concave rotors 9, and the lever bracket 14 is provided with two levers 10; the convex-concave rotor 9 is provided with driven gear 15, cam 16 and concave wheel 17, and driving gear 12 meshes with driven gear 15 (see ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com